Method for processingFischer-Tropsch wax production series products

A series of products and processing fee technology, applied in the field of processing fee-Tropsch wax production series products, can solve the problems of affecting product quality, product purpose, carbon deposition and coking, etc., to achieve rich product lines and strong product pertinence , The effect of high operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

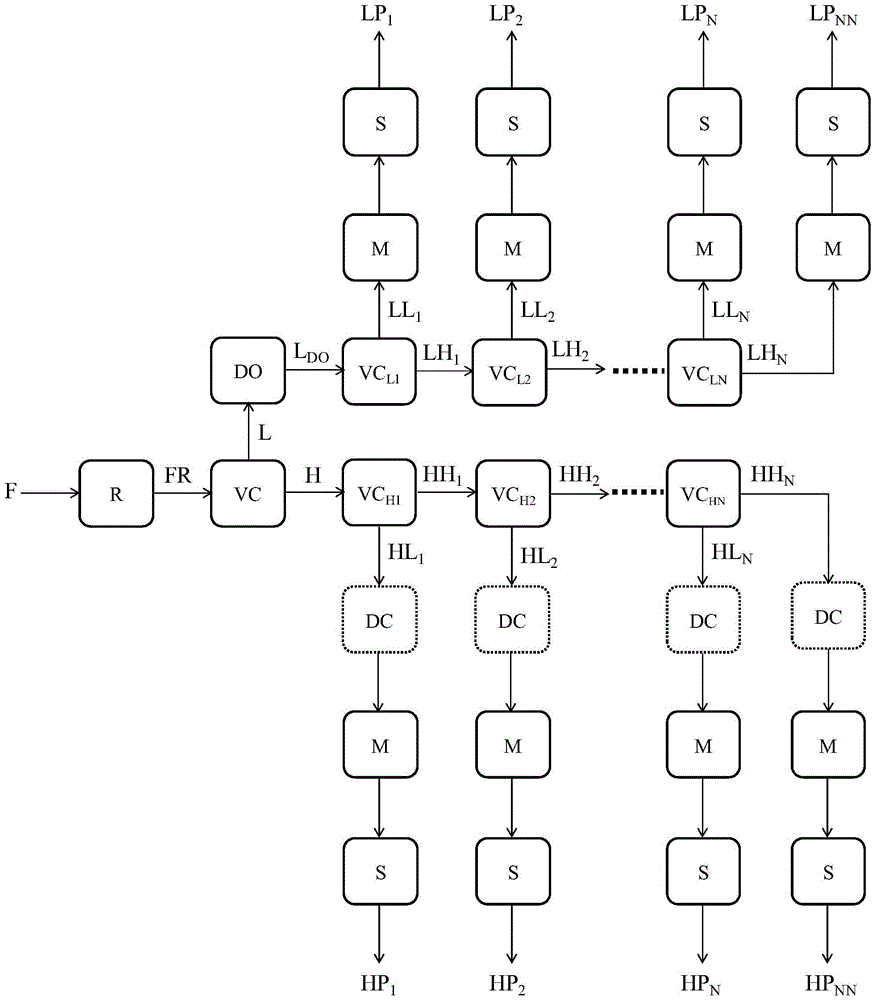

Method used

Image

Examples

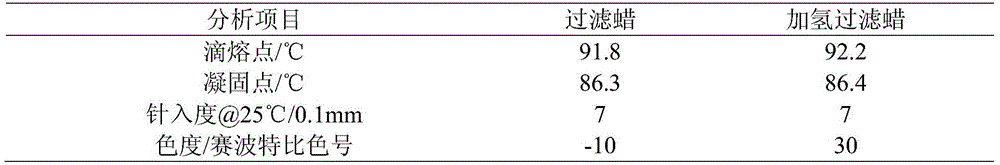

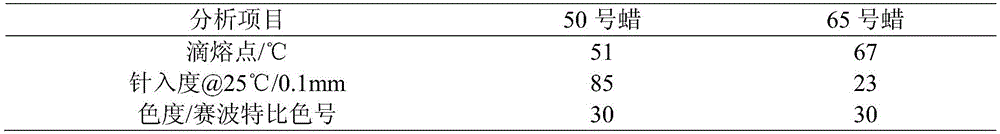

Embodiment 1

[0048] The Fischer-Tropsch synthetic filter wax obtained by a low-temperature Fischer-Tropsch synthesis process is used as raw material, and the hydrogenated filter wax is obtained through hydrogenation refining. The hydrogenation temperature is 310 ° C, and the reaction pressure is 6 MPa. The properties of the material before and after hydrogenation are shown in Table 1. The hydrogenation filtration wax enters the thin-film evaporator, the operating temperature is 250°C, and the operating pressure is 30Pa, and the hydrogenation filtration wax is separated into a Fischer-Tropsch light wax oil component and a Fischer-Tropsch heavy wax group with an end boiling point of about 500°C point. The Fischer-Tropsch light wax oil component enters the deoiling unit, and the deoiled Fischer-Tropsch light wax enters the short-path evaporator with an operating temperature of 125°C and an operating pressure of 0.7Pa to evaporate the diesel fraction and the remaining Fischer-Tropsch light wax ...

Embodiment 2

[0059] Fischer-Tropsch synthesis filter wax obtained by another Fischer-Tropsch synthesis process was used as raw material, and hydrogenated filter wax was obtained through hydrogenation refining. The hydrogenation temperature was 300°C and the reaction pressure was 10MPa. The hydrogenated filtration wax enters the thin-film evaporator, the operating temperature is 260°C, and the operating pressure is 30Pa, and the hydrogenated filtration wax is separated into a Fischer-Tropsch light wax oil component and a heavy Fischer-Tropsch wax component with an end boiling point of about 600°C . The Fischer-Tropsch light wax oil component enters the deoiling unit, and the deoiled Fischer-Tropsch light wax enters the short-path evaporator with an operating temperature of 125°C and an operating pressure of 0.7Pa to evaporate the diesel fraction and the remaining Fischer-Tropsch light wax The high quality wax component enters the next stage evaporator. The Fischer-Tropsch light wax compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com