Collagen foaming agent, compound modified collagen foaming agent and their preparation methods

A collagen and foaming agent technology, which is applied in the field of fine chemicals and achieves good application prospects, good foaming stability and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

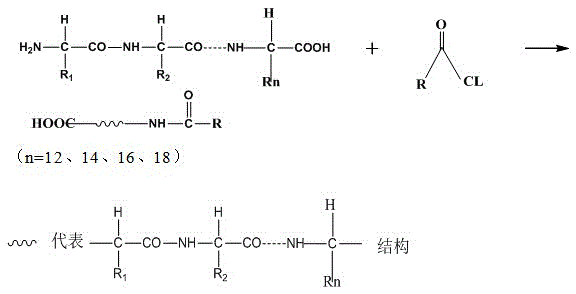

[0037] The preparation method of above-mentioned collagen foaming agent is realized by the following steps:

[0038] Step 1: Preparation of hydrolyzed gelatin:

[0039] Make gelatin with a dry weight of 20g into an aqueous solution with a mass fraction of 10%~30%, raise the temperature to 50°C, adjust the pH to 8~9 after the gelatin is completely dissolved, and use alkaline protease with a dry weight of 0.5%~3% of the gelatin Hydrolyze the gelatin, after reacting for 1h~4h, heat up to 90°C to inactivate the enzyme, and filter to obtain the hydrolyzed gelatin solution;

[0040] Step 2: Adjustment of the pH of the gelatin solution:

[0041] Adjust the hydrolyzed gelatin solution so that its pH reaches 9-10;

[0042] Step 3: Preparation of collagen foaming agent:

[0043] Add 0.5~3.0g of long-chain fatty acid chloride to the hydrolyzed gelatin solution, stir and react at 30~80°C for 1~6h, and prepare collagen egg foaming agent.

[0044] In step 1 and step 2, the pH adjustment...

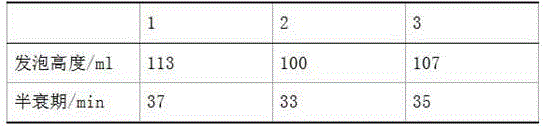

Embodiment 1

[0050] Step 1: Preparation of hydrolyzed gelatin:

[0051] Make 20g dry weight of gelatin into an aqueous solution with a mass fraction of 10%, raise the temperature to 50°C, adjust the pH to 9 after the gelatin is completely dissolved, hydrolyze the gelatin with alkaline protease of 0.5% gelatin dry weight, react for 4 hours, and raise the temperature Heat to 90°C to inactivate the enzyme, and filter to obtain the hydrolyzed gelatin solution;

[0052] Step 2: Adjustment of the pH of the gelatin solution:

[0053] Adjust the hydrolyzed gelatin solution so that its pH reaches 9;

[0054] Step 3: Preparation of collagen foaming agent:

[0055] Add 3.0 g of long-chain fatty acid chlorides to the hydrolyzed gelatin solution, and stir and react at 30°C for 6 hours to prepare a foaming agent for collagen eggs;

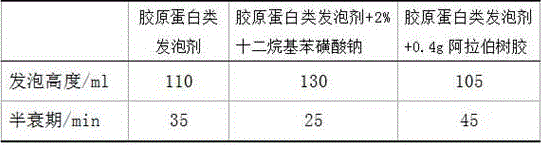

[0056] Step 4: Preparation of collagen compound modified foaming agent:

[0057] Adding 0.05% sodium dodecylbenzene sulfonate based on the mass of the collagen foaming a...

Embodiment 2

[0062] Step 1: Preparation of hydrolyzed gelatin:

[0063] Make 20g dry weight of gelatin into an aqueous solution with a mass fraction of 20%, raise the temperature to 50°C, adjust the pH to 8 after the gelatin is completely dissolved, hydrolyze the gelatin with alkaline protease with a dry weight of 1.5% gelatin, and react for 2.5 hours, Raise the temperature to 90°C to inactivate the enzyme, and filter to obtain the hydrolyzed gelatin solution;

[0064] Step 2: Adjustment of the pH of the gelatin solution:

[0065] Adjust the hydrolyzed gelatin solution so that its pH reaches 9;

[0066] Step 3: Preparation of collagen foaming agent:

[0067] Add 1.5 g of long-chain fatty acid chlorides to the hydrolyzed gelatin solution, stir and react at 55°C for 3 hours to prepare a foaming agent for collagen eggs;

[0068] Step 4: Preparation of collagen compound modified foaming agent:

[0069] Adding 0.30% sodium dodecylbenzene sulfonate based on the mass of the collagen foaming a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com