Patents

Literature

34 results about "Gelatin hydrolysate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

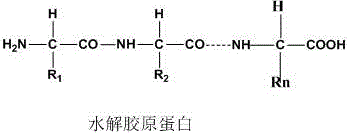

Gelatin is an irreversibly hydrolyzed form of collagen, wherein the hydrolysis results in the reduction of protein fibrils into smaller peptides, which will have broad molecular weight ranges associated with physical and chemical methods of denaturation, based on the process of hydrolysis.

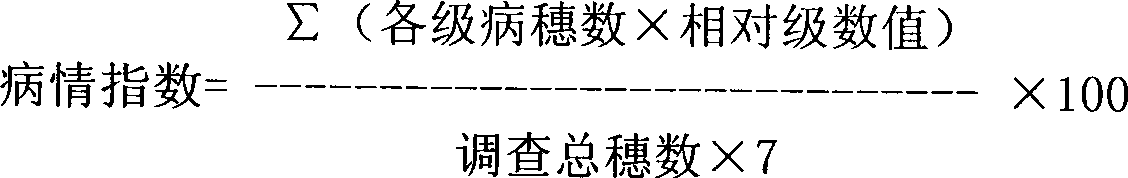

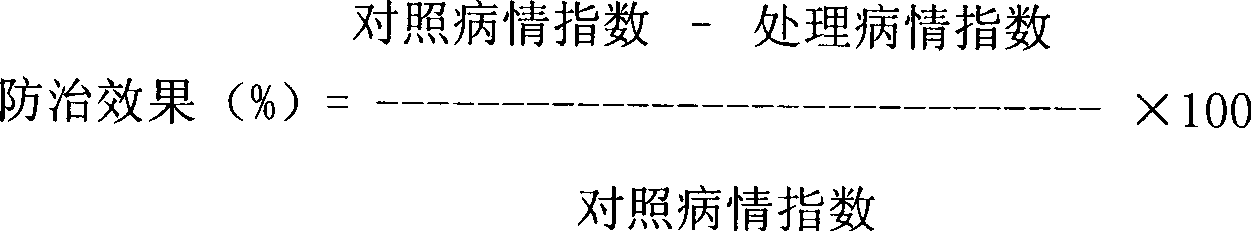

Biological preparation capable of preventing and treating cruciferae club root and use thereof

InactiveCN101416641AGood control effectSolve prevention and control problemsBiocideBacteriaSucroseRussulaceae

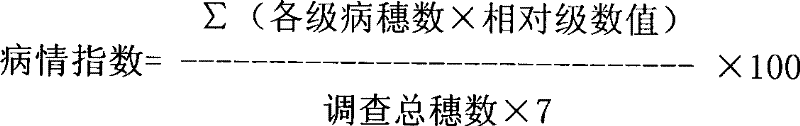

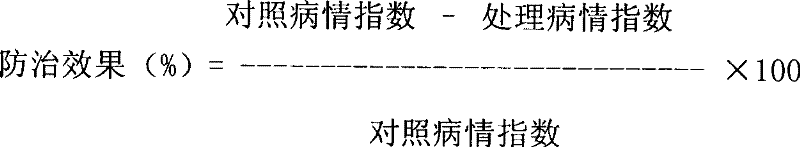

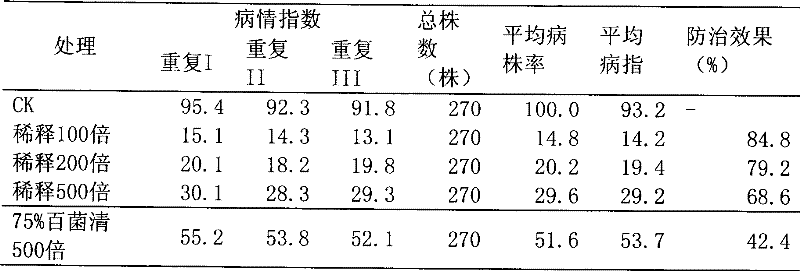

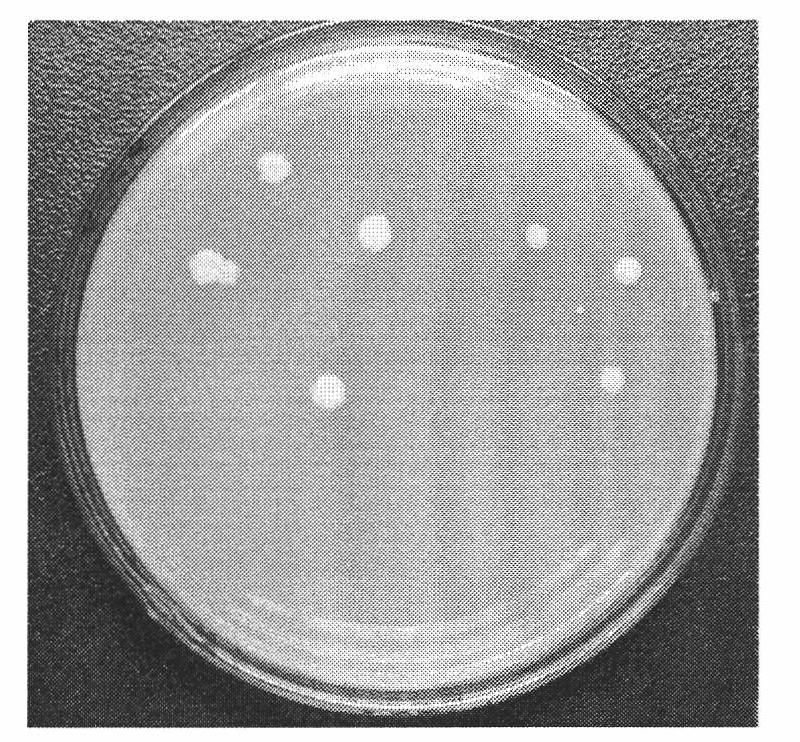

The invention relates to a biological agent against crucifer club root and application thereof, belonging to the technical field of bio-pesticide. The strain for production is Bacillus subtilis XF-1, whose preserving number is CGMCC NO.2357. The stain has the characteristics as follows: (1) the primary colony on the LB culture substrate is white and round having a wet surface; the later colony is light yellow having uneven edge with dry and crimple surface; observed from the microscope, the strain is short-bar shaped and movable with spore, peritricha and dimension of 0.7 - 0.8 * 2.0-2.4 mum; (2) the strain is Gram-positive and aerobic and makes use of glycogen, sugar, citrate, gelatin hydrolysate, starch and casein, but does not make use of cellulose, tyrosine and catalase positive; (3) the stain has the function of sterilization, disease prevention, and yield improvement. The embodiment of the invention is as follows: using the test tube of Bacillus subtilis XF-1 stain, shake cultivation, and culture solution for fermentation to prepare biological agent, then applying the biological agent to the rhizosphere soil of crucifer crops, thereby having good effect in preventing and treating, and simple production.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Modified membrane fabric, preparation method and application thereof

ActiveCN103976886AStrong residentReduce evaporationCosmetic preparationsAntipyreticPullulanCarrageenan

The invention provides a modified membrane fabric and a preparation method and application of the modified membrane fabric. The surface of the modified membrane fabric is coated with a polymer or polymer dispersion, and the polymer in the polymer or polymer dispersion may be polysaccharide, polypeptide and protein, may be an artificial polymerized polymer or may be a modified natural high polymer material or a mixture thereof, including but not limited to one or more selected from the group consisting of gelatins (such as gelatin and gelatin hydrolysate), cellulose ethers (e.g., carboxymethyl cellulose and hydroxyethyl methyl cellulose), modified starches (e.g., pullulan and hydroxypropyl starch), PVP, PVA, hyaluronic acids, albumin, chitosan, dextran, Arabic gum, xanthan gum, carrageenan, pectin, konjac gum, agar, Carbomer, carrageenin, polyvinylpyrrolidone, polyacrylamide, polyacrylate and polyacrylic acid and its derivatives. When the modified membrane fabric comes across water in use, the polymer on the surface of the modified membrane fabric can bond with water molecules to form a water retention system which has better retention performance compared with pure water and enables an evaporation speed to be slower and retention performance on the skin to be better.

Owner:李和伟

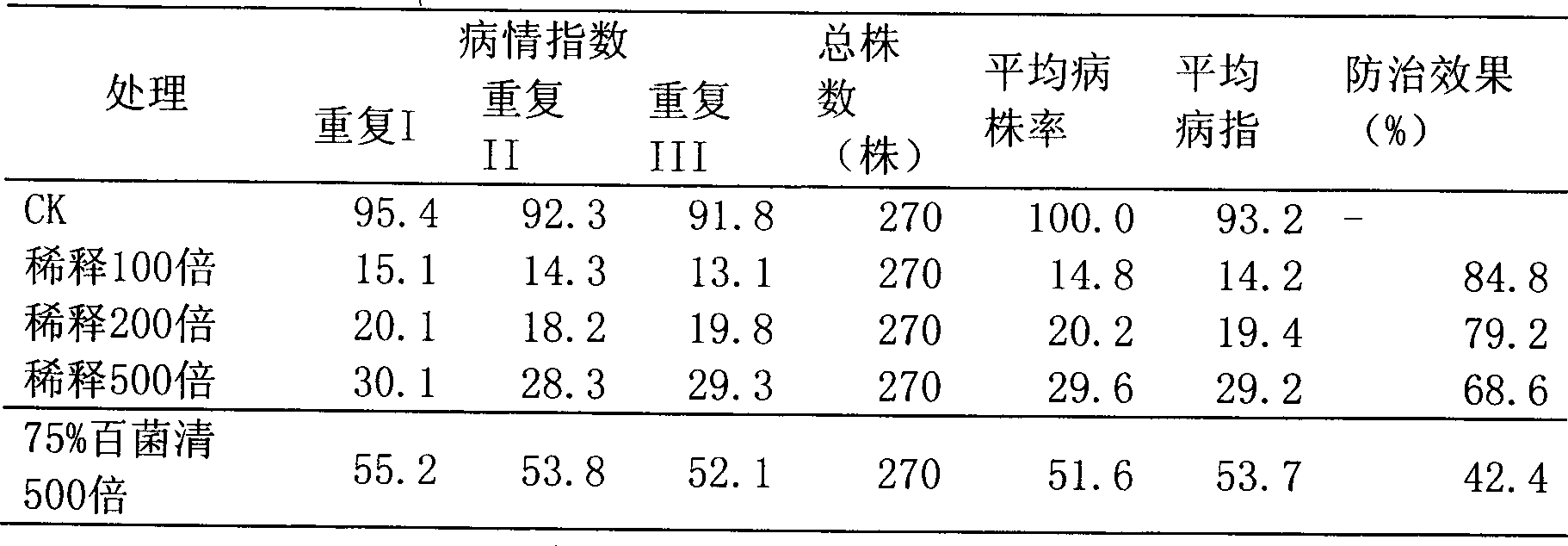

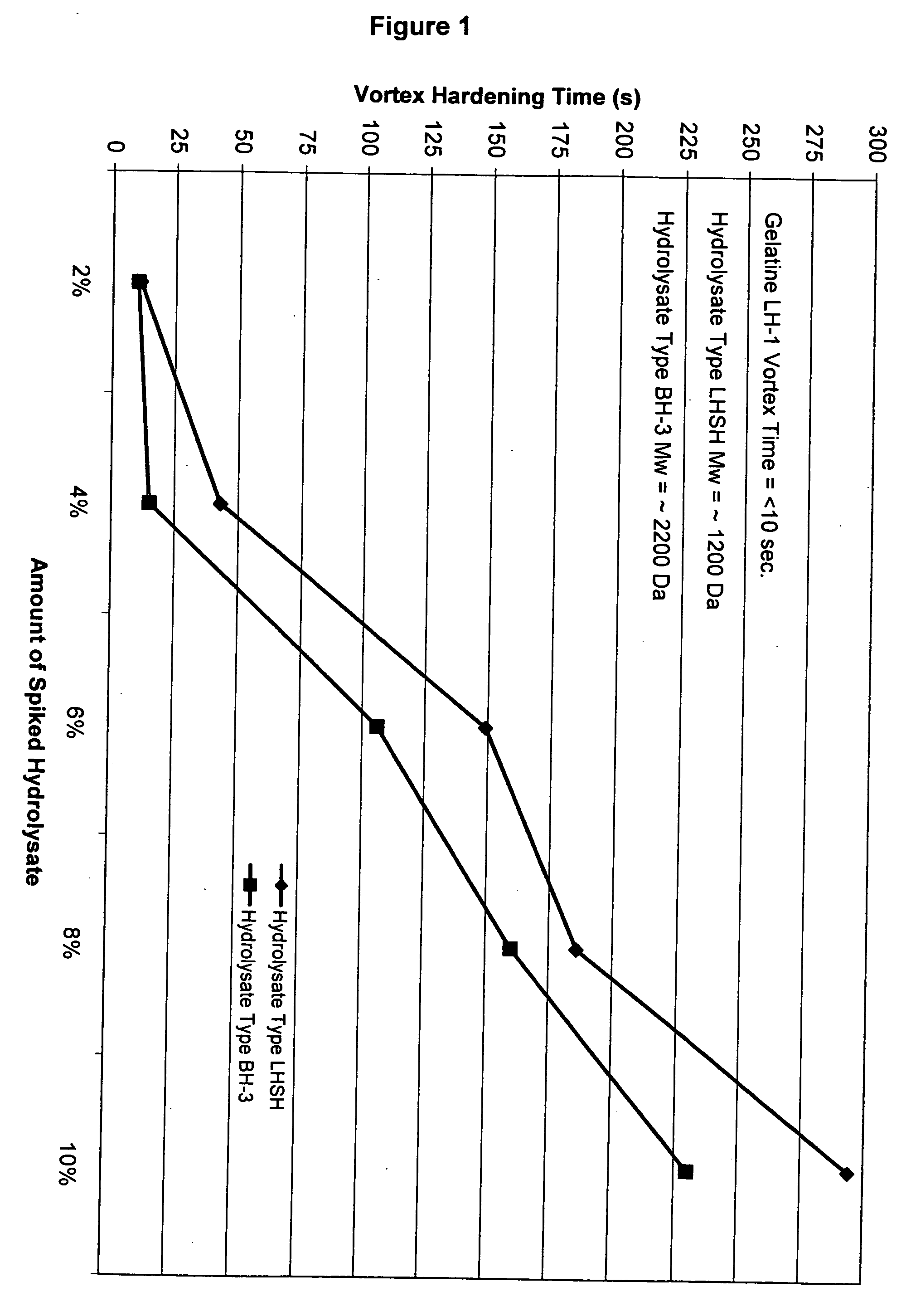

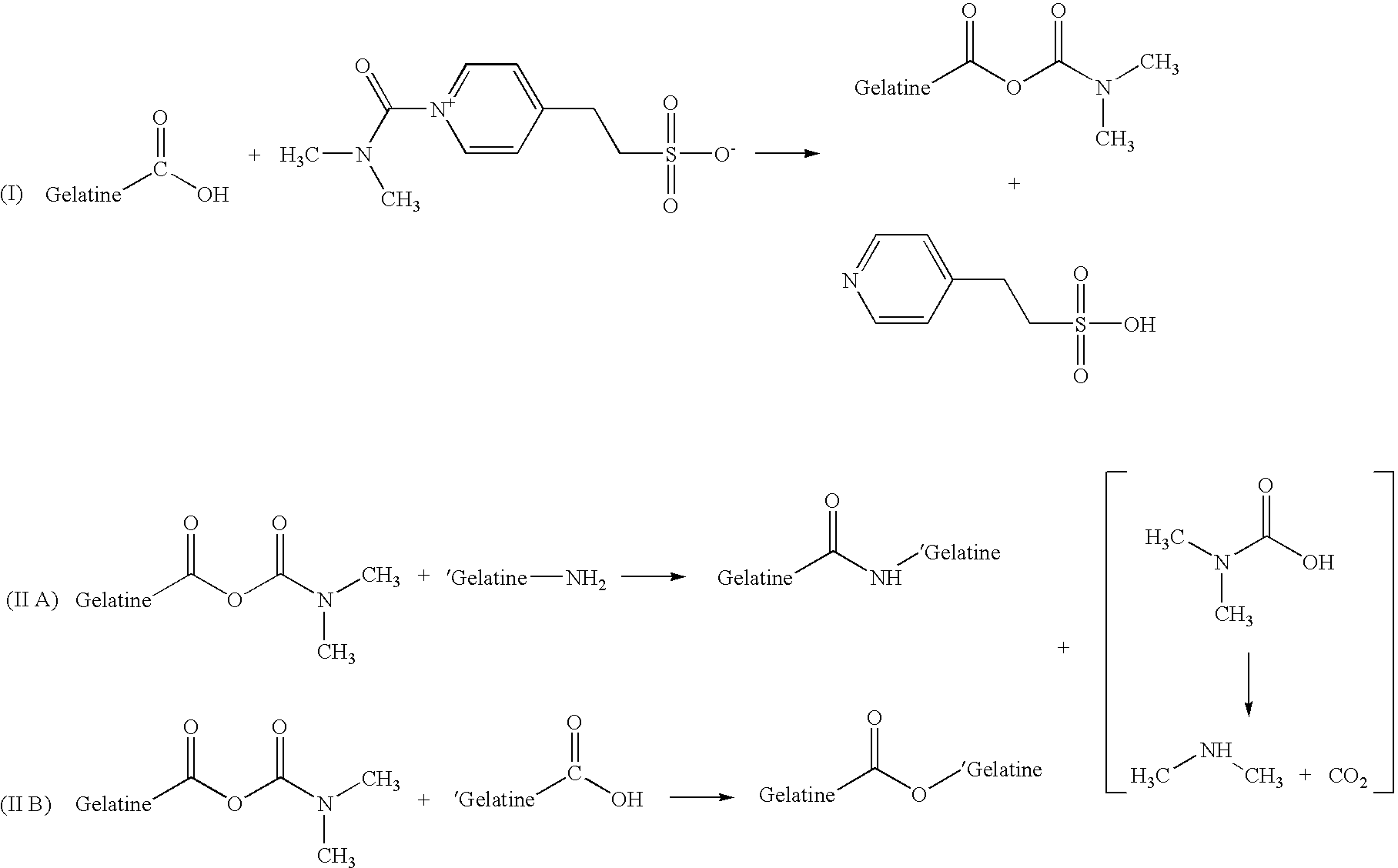

Process for making a low molecular weight gelatine hydrolysate and gelatine hydrolysate compositions

ActiveUS20060269987A1Reduce crosslinkingImprove propertiesIn-vivo radioactive preparationsPeptide/protein ingredientsGelatin hydrolysateDissolution

The present invention provides a process to make a gelatine hydrolysate, a gelatine hydrolysate and gelatine compositions comprising gelatine hydrolysates. More specifically, the invention provides gelatine compositions having improved cross-linking and dissolution properties.

Owner:GELITA AG

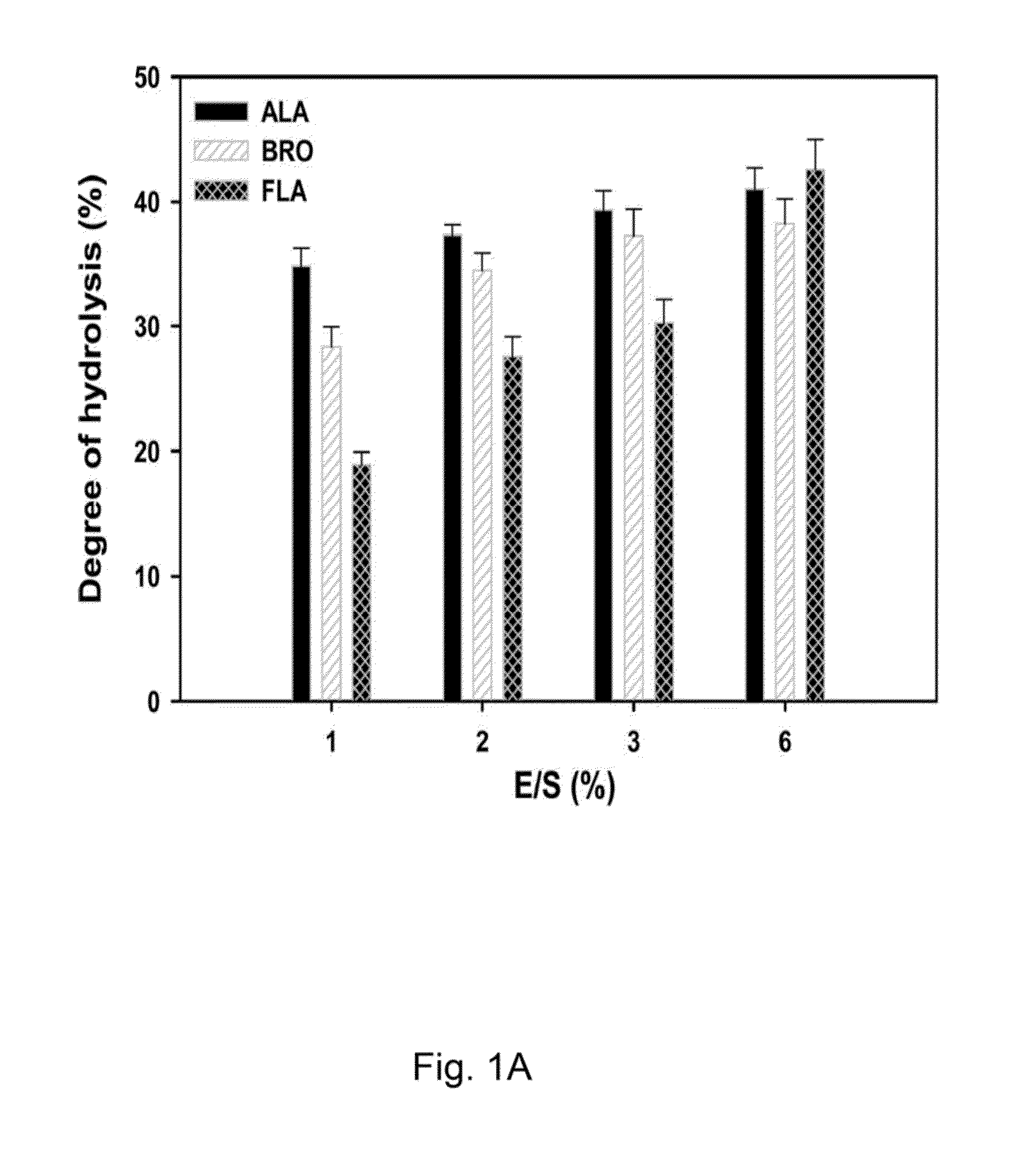

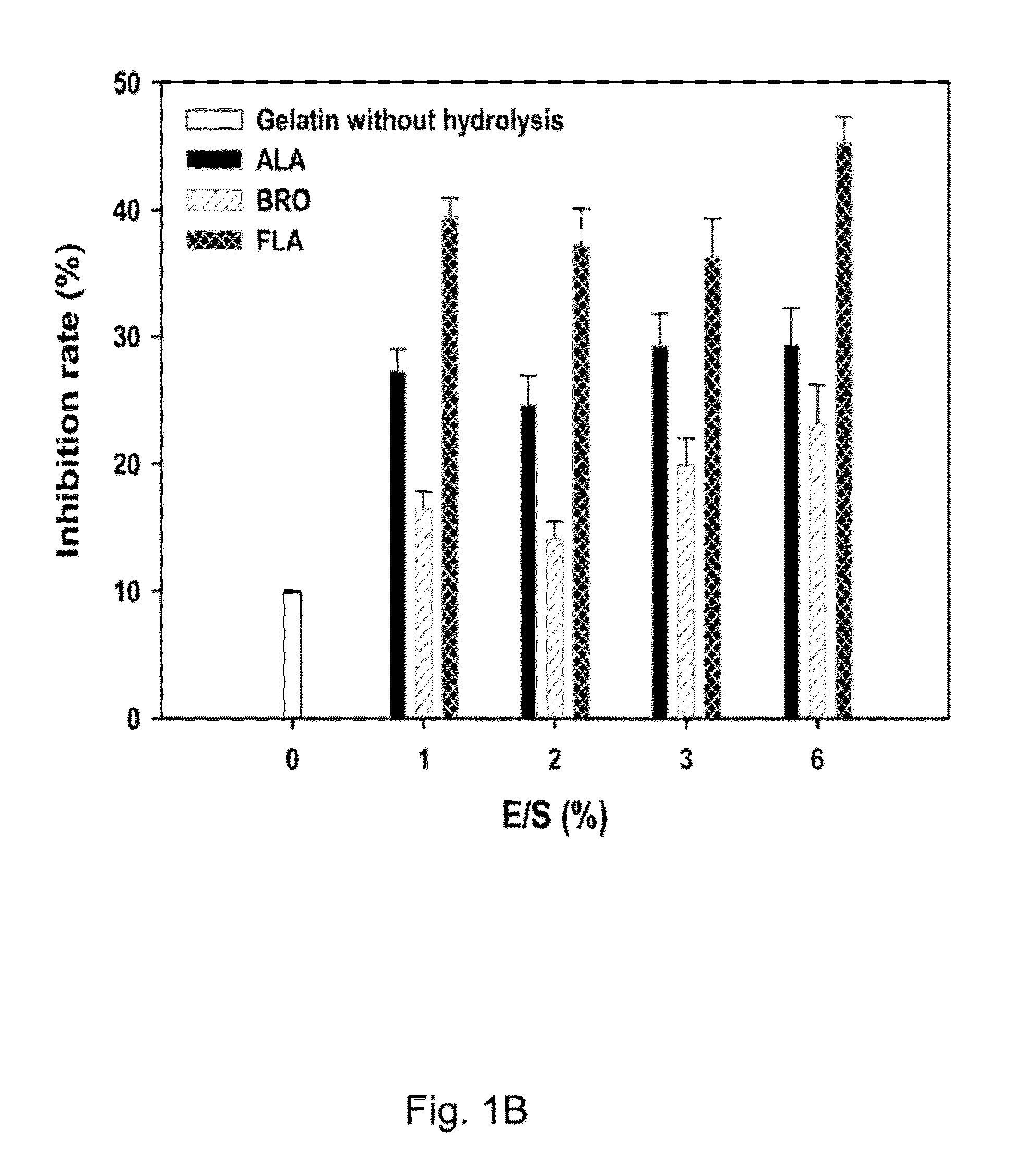

Peptide for inhibiting dipeptidyl-peptidase iv

InactiveUS20140193463A1Metabolism disorderTetrapeptide ingredientsGelatin hydrolysateEnzymatic digestion

Owner:CHINA MEDICAL UNIVERSITY(TW)

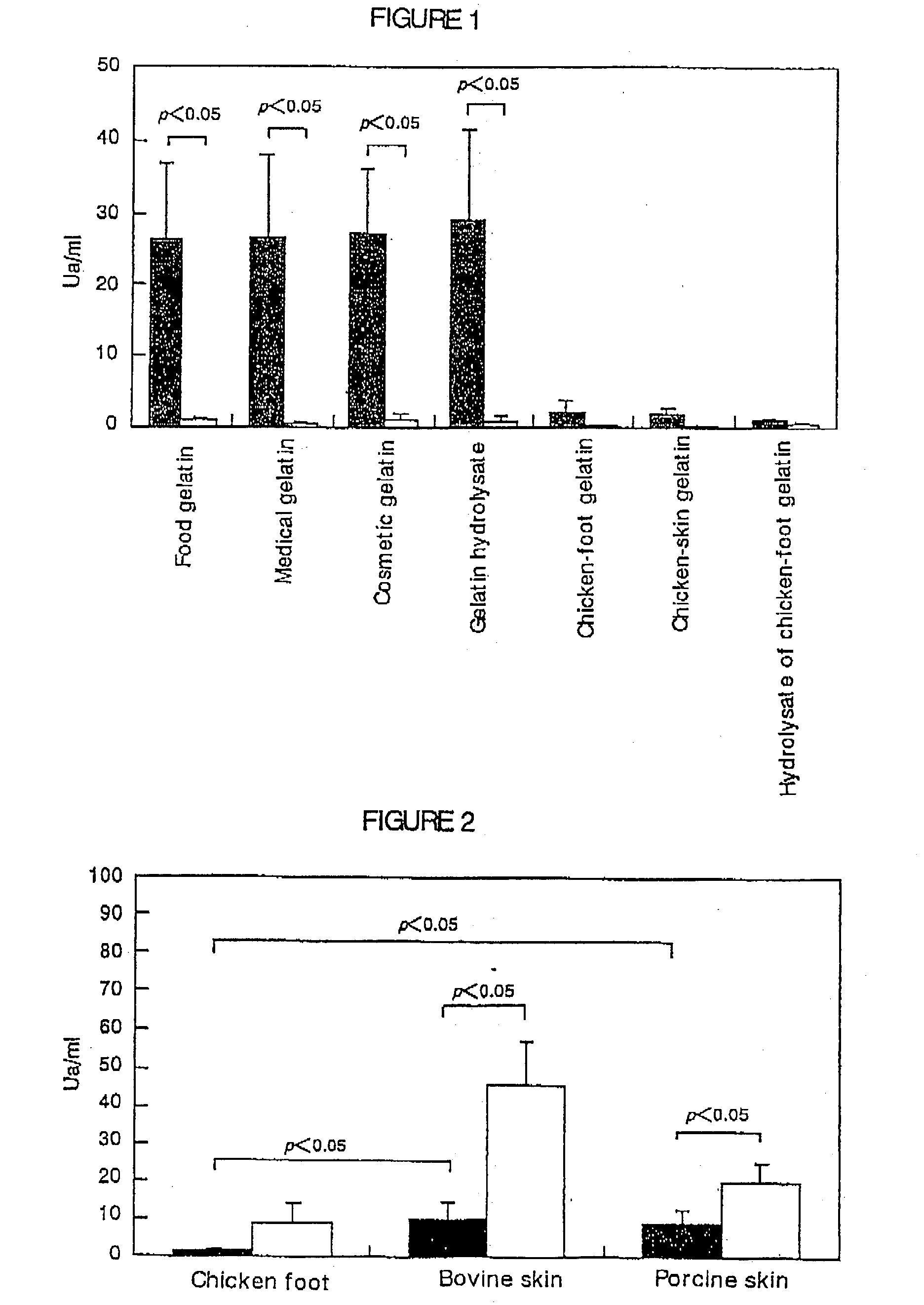

Hypoallergenic gelatin

InactiveUS20030044456A1Cosmetic preparationsPeptide/protein ingredientsBiotechnologyAntiendomysial antibodies

This invention provides gelatin and gelatin hydrolysate peptide for food, medical and cosmetic use derived from such raw materials as poultry skins, bones and / or tendons, with an isoelectric point at pH 7-10, and characterized by no or low antigen-antibody reactivity to the serum of gelatin-allergic individuals. Since the gelatin and its hydrolysate peptide of the invention are hypoallergenic, they can safely be used for gelatin-allergic individuals and for food, medicine and cosmetics, for which the safety is particularly required.

Owner:NIPPON HAM

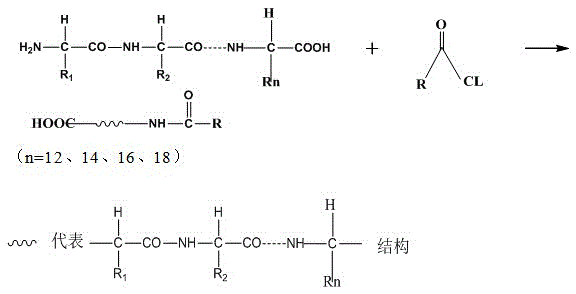

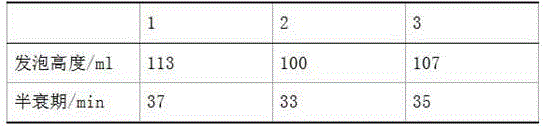

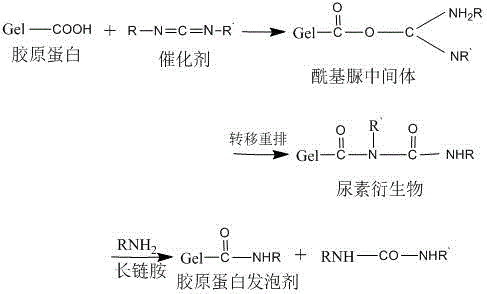

Collagen foaming agent, compound modified collagen foaming agent and their preparation methods

InactiveCN105543315AGood foam stabilityImprove the environmentFermentationResource utilizationDissolution

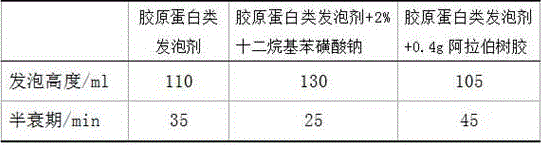

The invention relates to a collagen foaming agent, a compound modified collagen foaming agent and their preparation methods. The preparation method of the collagen foaming agent comprises preparing a gelatin aqueous solution, carrying out heating dissolution, adjusting pH and carrying out alkali protease hydrolysis to obtain a hydrolyzed gelatin solution, adjusting pH of the hydrolyzed gelatin solution, adding long-chain fatty acid chloride into the solution and carrying out a stirring reaction process to obtain the collagen foaming agent. The preparation method of the compound modified collagen foaming agent comprises adding sodium dodecyl benzene sulfonate or Arabic gum into the collagen foaming agent so that the collagen foaming agent is subjected to physical compound modification and forms the compound modified collagen foaming agent. The novel collagen foaming agent is prepared through the reaction of the long-chain fatty acid chloride and collagen. Through physical compound modification of the novel collagen foaming agent, leather waste resource utilization is realized. The invention provides the collagen foaming agents with excellent performances.

Owner:SHAANXI UNIV OF SCI & TECH

Fruit and vegetable cleaning agent and preparation process thereof

InactiveCN102115700AEasy to disinfectEasy to useOrganic non-surface-active detergent compositionsGelatin hydrolysateSodium citrate

The invention discloses a fruit and vegetable cleaning agent and a preparation process thereof, and the invention belongs to the cleaning field. The fruit and vegetable cleaning agent is prepared from the materials of gelatin with a molecular weight about 10000, hydrolytic gelatin, ethanol with a concentration of 75%, sodium citrate with a concentration of 96%, and deionized water in proportion. The preparation process of the fruit and vegetable cleaning agent as follows: gelatin and hydrolytic gelatin are dissolved in deionized water according to a formulation, and are immersed and stirred for 30 minutes to be fully dissolved; sodium citrate is dissolved in water with continuous stirring until sodium citrate is fully dissolved; the sodium citrate solution is added slowly to the mixture of gelatin and hydrolytic gelatin solutions; ethanol is added finally; and the mixture is mixed uniformly to obtain the product. The cleaning agent cleans dirty, can achieve ideal disinfection effect, and can wash dirt, pesticide, etc. on the surface of fruit and vegetable. The product is characterized by convenient use, environmental protection and sanitation, convenient preparation, and low cost, and the product is easy to popularize.

Owner:刘永刚

Method for preparing hydrolytic gelatin using combined enzyme

InactiveCN1511910AImprove stabilitySolve the problem of poor stabilityGlue/gelatin preparationFermentationGelatin hydrolysatePhosphate

The preparation process of hydrolytic gelatin with combined enzyme includes compounding water solution with gelatin material, regulating pH value with citric acid and phosphate buffering system, heating to reaction temperature, throwing enzyme via stirring, heating to killing enzyme, filtering, concentrating and drying to obtain hydrolytic gelatin. The combined enzyme contains any two of neutral proteinase containing AS1.398, papain, trypase and pineapple proteinase; the reaction has temperature suitable for the enzyme components, system pH value of 5-8.5 and reaction period of 0.5-5 hr; and the single enzyme adding amount is 0.01-2 wt% of gelatin. The enzyme components are added after being mixed or successively to degrade gelatin, and the process can decrease molecular weight of hydrolytic gelatin, raise hydrolytic gelatin solution stability and eliminate bad smell.

Owner:北京华达杰瑞生物技术有限公司

Biological preparation capable of preventing and treating cruciferae club root and use thereof

InactiveCN101416641BGood control effectSolve prevention and control problemsBiocideBacteriaSucroseRussulaceae

Owner:YUNNAN AGRICULTURAL UNIVERSITY

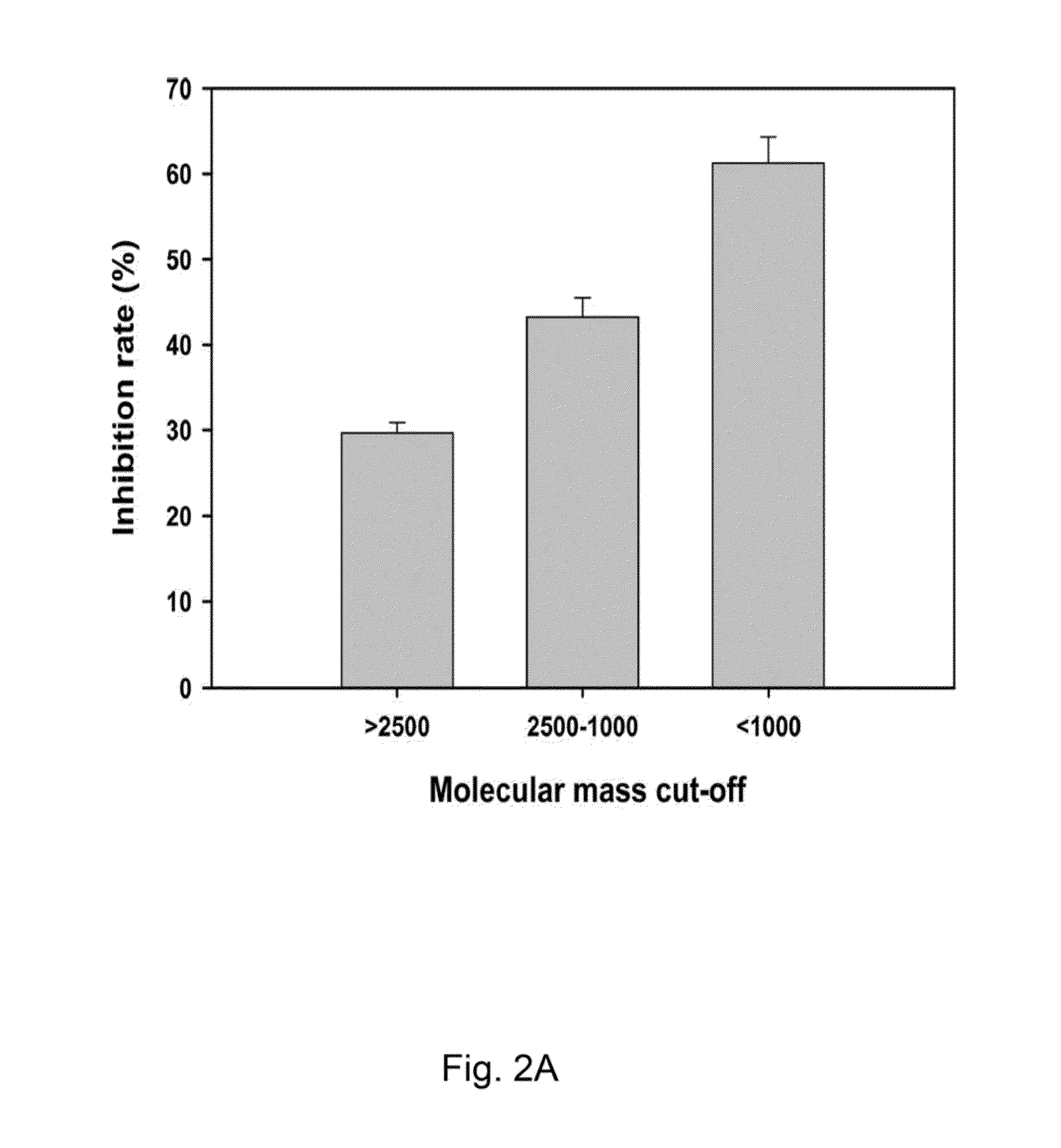

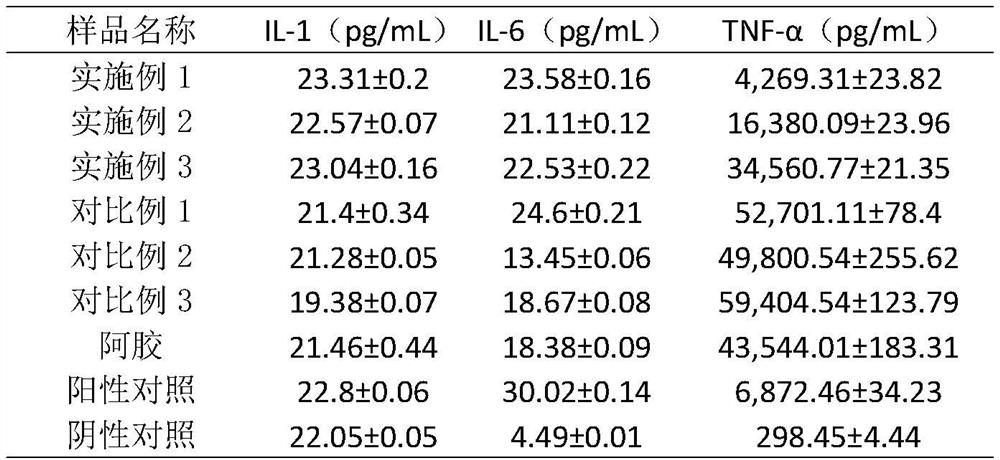

Preparation method and product of low-pro-inflammatory reaction donkey-hide gelatin peptide

PendingCN113930472AReduced pro-inflammatory response capacityEasy to useHydrolysed protein ingredientsImmunological disordersGelatin hydrolysateSpecific enzyme

The invention discloses a preparation method and a product of low-pro-inflammatory reaction donkey-hide gelatin peptide. The preparation method comprises the following steps: (1) crushing donkey-hide gelatin blocks; (2) co-dissolving the crushed colla corii asini obtained in the step (1) in non-specific enzyme chain enzyme protease E, and carrying out enzymolysis for 3-5 hours under an enzymolysis condition, so as to obtain an enzymolysis colla corii asini solution; and (3) adding protease into the enzymatic hydrolysate obtained in the step (2) for enzymolysis, wherein the molecular weight of an enzymolysis product is made to range from 1000 Da to 3000 Da, high-temperature enzyme deactivation is carried out, the donkey-hide gelatin enzymatic hydrolysate is obtained, and (4) the donkey-hide gelatin enzymatic hydrolysate in the step (3) is freeze-dried, and the donkey-hide gelatin peptide is obtained. On one hand, the anti-inflammatory response capability of the donkey-hide gelatin is reduced, on the other hand, the anti-oxidation capability of the product is provided, and meanwhile, the relatively strong positive immunoregulation capability is still maintained, so that the side effects of the donkey-hide gelatin and the donkey-hide gelatin hydrolysate, which cause inflammation, are reduced, the phenomenon of getting inflamed is reduced, the use limitation of the donkey-hide gelatin is reduced, and the donkey-hide gelatin is safer to use.

Owner:武汉珈诗丽科技有限公司

Free-flowing gelatin composition

InactiveUS20090285963A1Simplified industrial processingSimple processCapsule deliveryAnimal proteins working-upGelatin hydrolysateWater activity

In order to provide a novel free-flowing gelatin composition, in particular for use as food precursor, which gelatin composition retains its flowability, in particular even at temperatures below 30° C., it is proposed that the free-flowing gelatin composition comprises an aqueous liquid, gelatin gel particles dispersed therein and / or dissolved gelatin hydrolysate and one or more sugar components, wherein the sum of the contents of gelatin, gelatin hydrolysate and sugar components(s) is selected such that the water activity (aw value) of the composition is less than or equal to 0.97.

Owner:GELITA AG

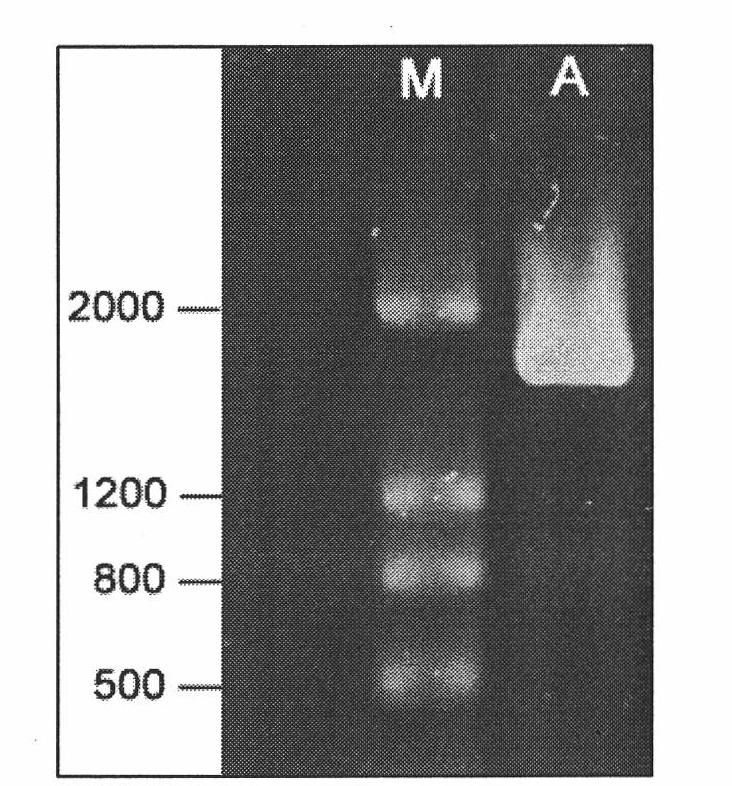

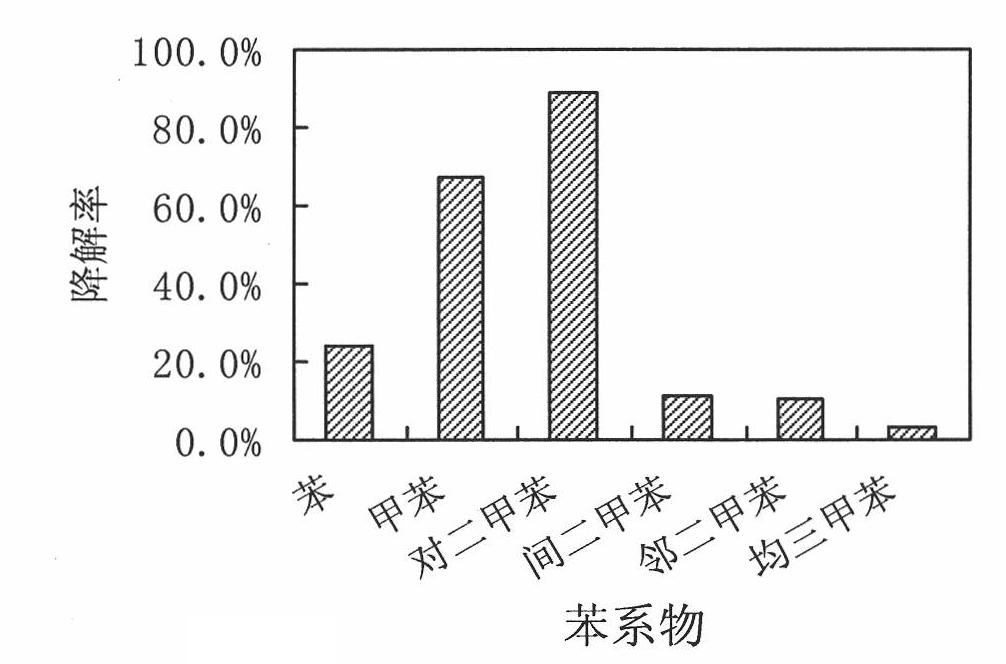

Facultative anaerobic benzene compounds-degrading bacterium

InactiveCN101892179AEfficient degradationAdaptableBacteriaWater contaminantsMesityleneDenitrification

The invention belongs to the technical field of microbe degradation, and discloses a facultative anaerobic benzene compounds-degrading bacterium, which is characterized in that the bacterium is Staphylococcus sciuri HBSD-A CCTCC No.M209283 and has been preserved in China Center for Type Culture Collection with the collection number of CCTCC No.M209283 on November 27, 2009. The bacterium has the milk white, round, opaque, sawteeth-edge, slightly convex and smooth-surface colonial morphology; the cells are spherical, Gram-positive and immobile; and the bacterium has the main biochemical characteristics of oxidase-negative and catalase-positive bacterium, utilization of glucose, fructose and sucrose instead of maltose, denitrification-positive and gelatin hydrolysate-positive bacterium, facultative anaerobic bacterium and growth temperature between 4 and 41 DEG C. The bacterium can efficiently degrade methylbenzene and dimethylbenzene under the anaerobic condition, can degrade benzene or mesitylene, and has the maximum 3d degradation rate of 89.0 percent for benzene compounds at the concentration about 175.8mg / L.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Gelatin hydrolysate pesticide scavenging agent and use method thereof

InactiveCN104450306ALow costSimple preparation processOrganic non-surface-active detergent compositionsGelatin hydrolysateSodium citrate

The invention provides a gelatin hydrolysate pesticide scavenging agent and a use method thereof. The gelatin hydrolysate pesticide scavenging agent is prepared by sequentially feeding ethanol and gelatin hydrolysate into a blending pot according to a certain ratio, slowly adding sodium citrate into the pot, adjusting the pH to be within 7-8, further adding essence, and finally adjusting the concentration with deionized water. When used, the gelatin hydrolysate pesticide scavenging agent is diluted to be a scavenging solution by using clean water in a certain ratio, and subsequently vegetables, fruits and the like can be soaked in the scavenging solution. The gelatin hydrolysate pesticide scavenging agent provided by the invention is efficient, environmental friendly, low in cost and wide in application prospect.

Owner:邬石根

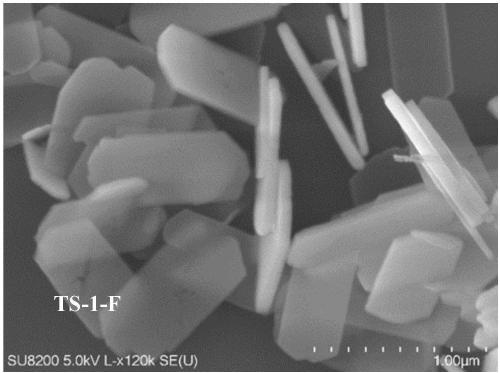

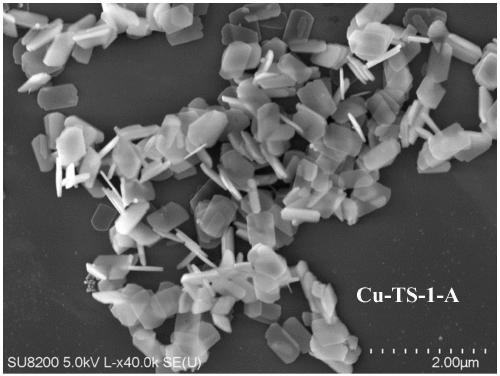

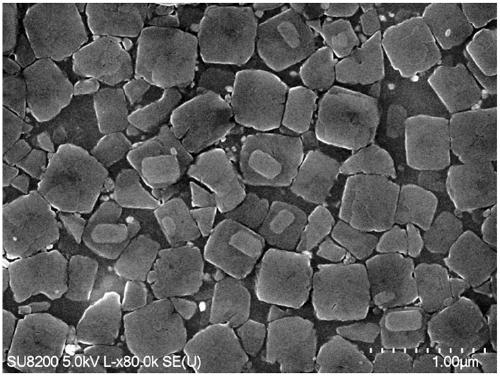

Laminar heteroatom molecular sieve and synthesizing method thereof

InactiveCN109607561AShort diffusion pathReduced Diffusion ResistanceNanotechnologyMolecular-sieve silicatesMolecular sieveWAS PROTEIN

The invention relates to the technical field of synthesis of catalysts, and provides laminar heteroatom molecular sieve and a synthesizing method thereof. The laminar heteroatom molecular sieve prepared by using the method has an MFI type topological structure, the maximum surface of nanosheets is parallel to the (0,2,0) crystal face, and the length of a straight channel can be controlled. Due toshort straight channels of the nanosheets, the diffusion path of a reaction is shortened, reactant molecules more easily make contact with the active center, the generated product is diffused out of the channels in time, the diffusion limitations of the molecules in the channels are reduced, carbon deposition is reduced, and the service life of a catalyst is prolonged. The laminar heteroatom molecular sieve prepared by using the method belongs to monodisperse nanosheets, the particle size is large, the particle size is in micron level, and the product is easily separated from mother liquor. Astructure modifier added in the synthesizing method is protein or polypeptide or gelatin or gelatin hydrolysates, the structure modifier is low in cost and easy to obtain and does not need to be additionally synthesized.

Owner:DALIAN UNIV OF TECH

Medicine composition

ActiveCN104840436ASmall metabolismThe degree of absorption has little effectOrganic active ingredientsPowder deliveryGuar gumExcipient

The invention relates to a medicine composition. The medicine composition comprises terazosin and an excipient, wherein the excipient is selected from mannitol, lactose, sorbitol, xylitol, glucose, maltose, glycine, soluble dextrin, xanthan gum, gelatine, hydrolyzed gelatine, Arabic gum, pectin, guar gum, peach gum, tragacanth gum, acacia gum, sodium carboxymethylcellulose, polyvinylpyrrolidone, carbomer, hydroxy propyl cellulose, hydroxypropyl methyl cellulose, alginate or is a combination thereof, wherein the weight ratio of the terazosin to the excipient is 1: (10 to 1000). The invention further relates to a method for preparing the medicine composition. The medicine composition disclosed by the invention has the excellent properties shown in the description.

Owner:北京安塞迩生物科技有限公司

Stabilising medium for alphagst in urine for use in an enzyme immunoassay

InactiveUS6071706APrevent loss of immunological activityEnhance immune responseSugar derivativesBacteriaGelatin hydrolysateEnzyme immunoassays

PCT No. PCT / IE94 / 00050 Sec. 371 Date Apr. 17, 1997 Sec. 102(e) Date Apr. 17, 1997 PCT Filed Oct. 17, 1994 PCT Pub. No. WO96 / 12191 PCT Pub. Date Apr. 25, 1996Stabilizing medium for urinary alpha GST contains a stabilizing amount of a non-enzyne protein, such as a mixture of equal amounts (w / v) of bovine serum albumin and gelatin hydrolysate, chelating agent and a buffer, such that the medium has a pH in the range 7.0-7.5, the medium being effective to prevent loss of alpha GST immunological activity. The stabilizing medium can be used to store urine samples at temperatures of the order of -20 DEG C. without any loss of alpha GST immunoreactivity of the type observed in samples which are stored without such a stabilizing medium. The stabilizing medium also improves the immunoreactivity of alpha GST when added to fresh urine which is stored temporarily at 2-8 DEG C. prior to assay for up to two hours.

Owner:ARGUTUS INTPROP

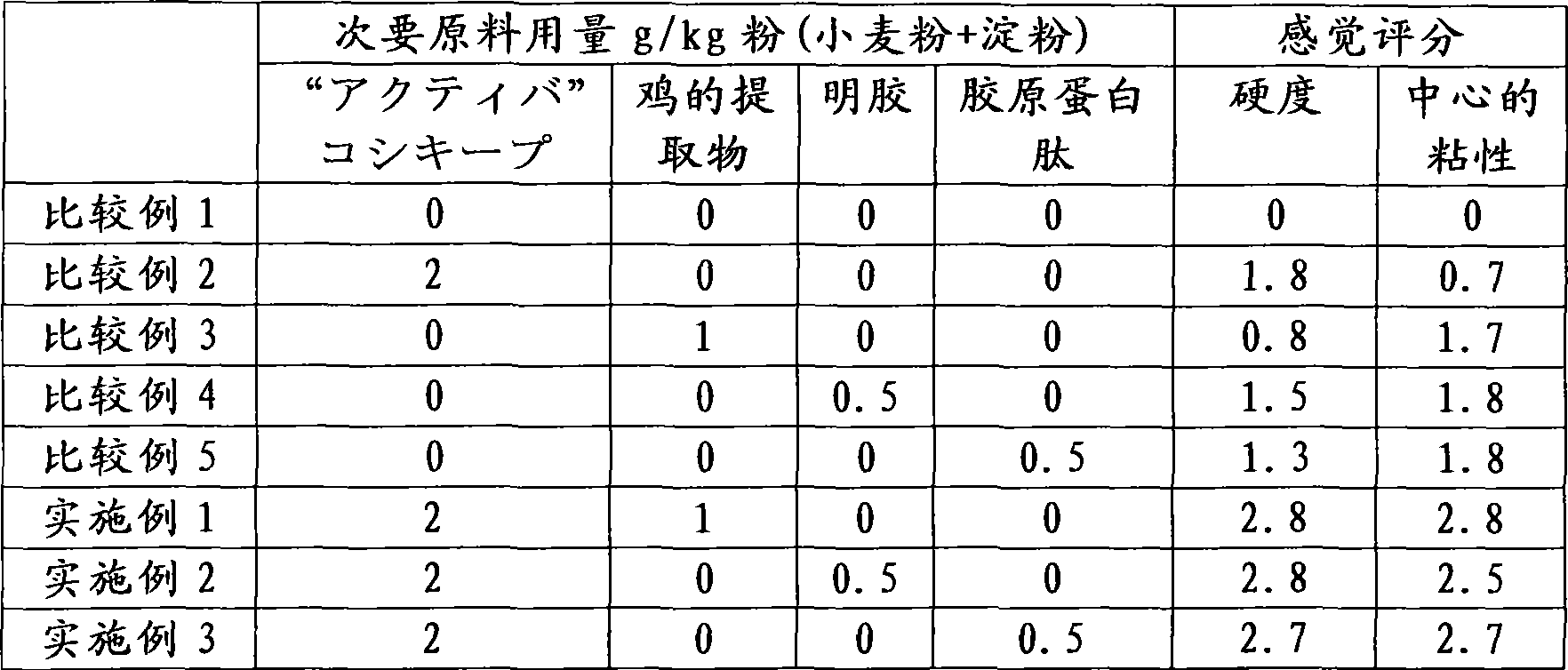

Enzyme preparation for instant noodle and method of producing instant noodle

InactiveCN101384182AGood modification effectHigh hardnessAcyltransferasesFood preparationGelatin hydrolysateAnimal extract

To provide: a method for providing an effect of modifying an instant noodle even when transglutaminase is added in a small amount; and a method of economically producing an instant noodle having a glutinous core portion and well-balanced texture. [MEANS FOR SOLVING PROBLEMS] Disclosed is a method of producing an the instant noodle, wherein transglutaminaze and at least one material selected from an animal extract, gelatin, and a gelatin hydrolysate.

Owner:AJINOMOTO CO INC

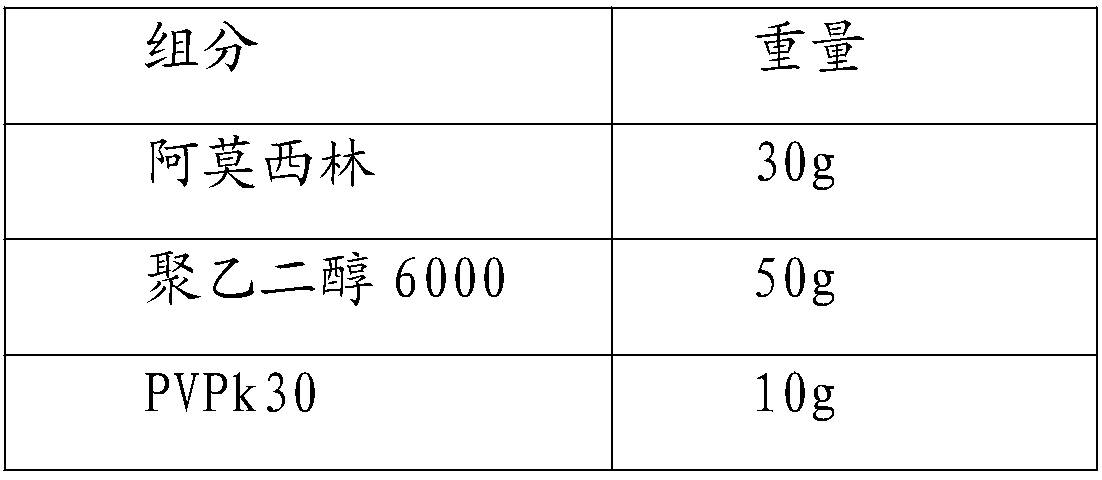

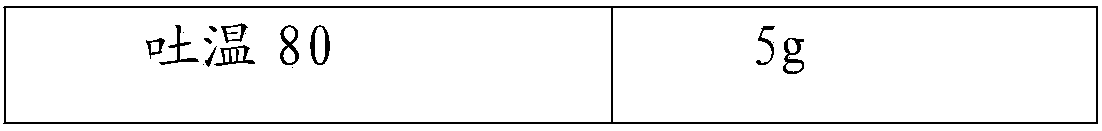

Amoxicillin soluble powder and preparation method thereof

ActiveCN108272756AImprove solubilityImprove physical stabilityAntibacterial agentsGranular deliveryGelatin hydrolysateTreatment effect

The invention relates to amoxicillin soluble powder and a preparation method thereof. The amoxicillin soluble powder is prepared from amoxicillin, gelatin hydrolysate with the average molecular weightbeing 1,500-3,000Da and a diluent, and preferably from the following components in percentage by weight: 10-30wt% of the amoxicillin, 20-50wt% of the gelatin hydrolysate with the average molecular weight being 1,500-3,000Da and 20-60wt% of sorbitol. The soluble powder can form a homogeneous liquid in water, and the solution is high in stability, more importantly, can provide effective efficacy for a long time and is durable and reliable in curative effect.

Owner:四川恒通动保生物科技有限公司

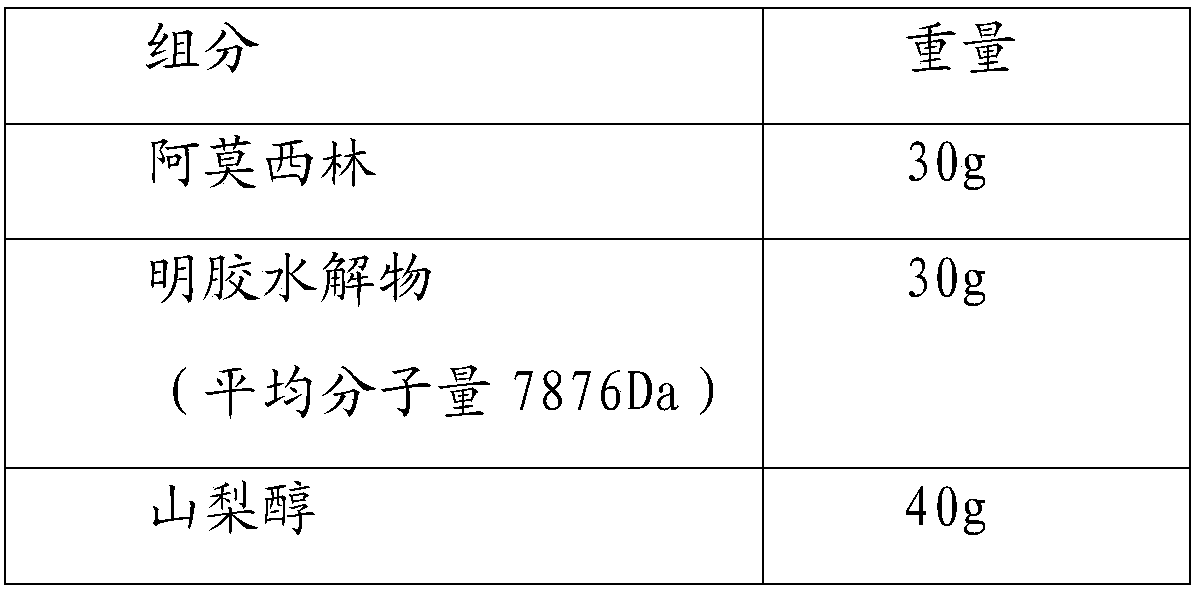

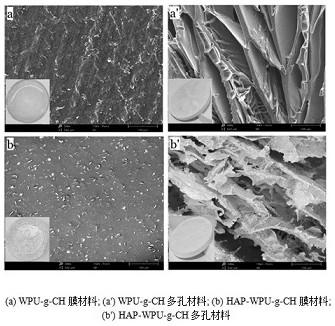

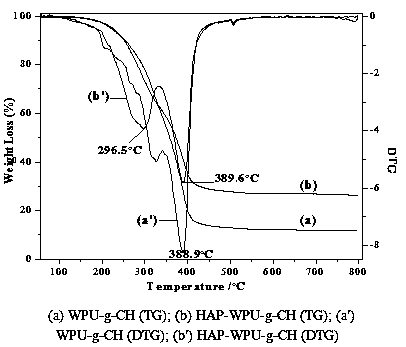

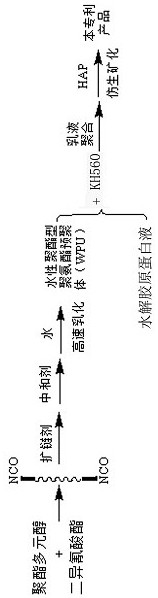

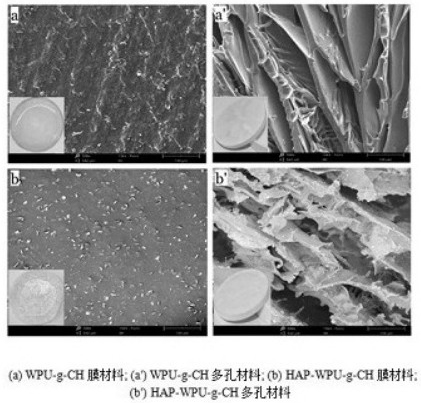

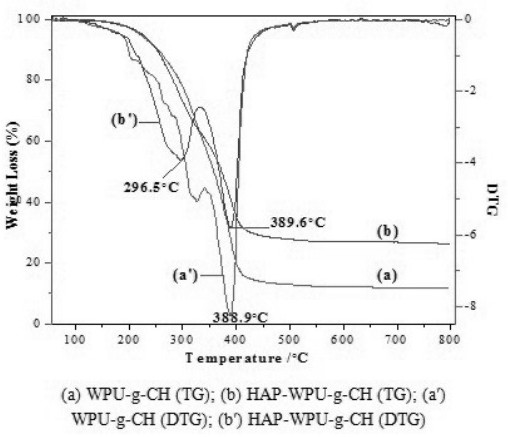

Preparation method of waterborne polyurethane (WPU)/collagen/hydroxyapatite (HAP) composite material

ActiveCN110240691AWith structural stabilityBiocompatibleTissue regenerationProsthesisPolyesterBiocompatibility Testing

The invention discloses a preparation method of a waterborne polyurethane (WPU) / collagen / hydroxyapatite (HAP) composite material. The composite material is prepared from the following components in parts by weight: diisocyanate, polyester polyol, a chain extender, a waterborne chain extender, a neutralizer, a hydrolyzed collagen solution, gamma-glycidoxypropyltrimethoxysilane (KH560), calcium chloride and sodium hydrogen phosphate. According to the preparation method, an emulsion polymerization reaction is performed on a polyester-type WPU prepolymer and a biochemical-level gelatin hydrolysate (GH), and external crosslink modification is further performed through KH560 to improve the hydrophobicity and adhesive film toughness of the material, thus preparing a WPU and GH graft copolymerization composite emulsion (WPU-g-GH). The invention aims to prepare the nano HAP composite material with good mechanical property, structural stability, biocompatibility and degradability, which is expected to be a potential bone scaffold repair material.

Owner:QILU UNIV OF TECH

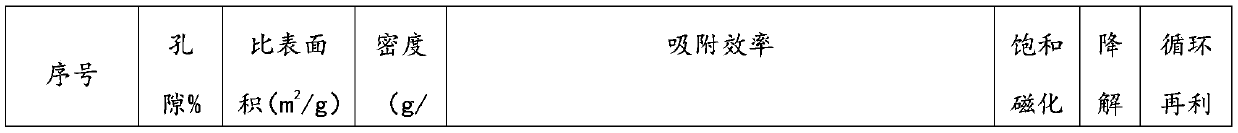

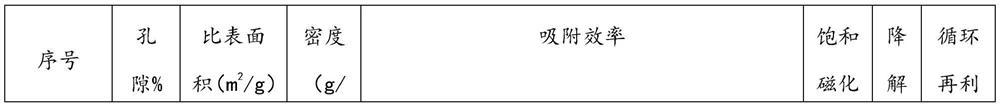

Method for preparing magnetic adsorption material from animal and plant wastes

ActiveCN110548494AImprove toughnessHigh strengthOther chemical processesSpecific water treatment objectivesPorosityFiber

The invention discloses a method for preparing a magnetic adsorption material from animal and plant wastes, and solves the problems that an existing magnetic adsorption material is poor in biodegradability and difficult to recycle, and the adsorption performance needs to be improved further. According to the technical scheme, crude fiber plant dregs are used as raw materials for preparation, hollow hydroxyapatite / copper ferrite nanoparticles are prepared through nanofiber crystallization, hydroxyapatite molding, medium-temperature template removal and copper ferrite loading, gelatin hydrolysate is prepared by ingeniously using animal waste gel, and hollow porous hydroxyapatite / copper ferrite nanoparticles are supported through crosslinking. According to the method, the process is simple, reaction conditions are mild, the raw materials are simple and easily available, the production cost is low, the method is easy to operate, the prepared adsorption material has high porosity and largespecific surface area, the adsorption performance of the material is greatly improved, the method has the advantages of repeated utilization and stable adsorption efficiency, complex water pollution can be treated, the recycling reproducibility and biodegradability are good, and the method is environmentally friendly.

Owner:HUBEI UNIV OF TECH

A kind of preparation method of waterborne polyurethane/collagen/hydroxyapatite composite material

ActiveCN110240691BSimple preparation processThe preparation process is stableTissue regenerationProsthesisPolyesterPolymer science

The invention discloses a method for preparing a water-based polyurethane / collagen / hydroxyapatite composite material, which comprises the following components in parts by weight: diisocyanate, polyester polyol, chain extender, water-based chain extender, neutralizer, Hydrolyzed Collagen Solution, γ‑Glycidyl Etheroxypropyl Trimethoxysilane (KH560), Calcium Chloride, Disodium Hydrogen Phosphate. In the present invention, polyester-type water-based polyurethane (WPU) prepolymer and biochemical grade gelatin hydrolyzate (GH) are used for emulsion polymerization, and KH560 is further modified by external linking to improve the hydrophobicity of the material and the toughness of the film, so that WPU and GH graft copolymerization compound emulsion (WPU‑g‑GH). The aim is to prepare a nano-HAP composite material with good mechanical properties, structural stability, biocompatibility and degradability, which is expected to become a potential bone scaffold repair material.

Owner:QILU UNIV OF TECH

Dietary fiber drink processing technology

The invention relates to a dietary fiber drink processing technology. The drink comprises raw materials in parts as follows: 100 parts of peels, 85 parts of water, 15 parts of glucose, 0.5 parts of citric acid and 0.2 parts of Vc. The technology comprises steps as follows: washing the peels with 0.5% of a hydrochloric acid solution, washing the solution with clear water, soaking the peels in 0.1% of a citric acid solution after washing, fishing the peels, cutting the peels into pieces, and then quickly placing the peels into the critic acid for soaking; mixing the peels with the raw materials to enable glucose to be dissolved thoroughly; adding a deoxidant containing anthocyanase prepared from asperigillus niger for decolorization, then adding 0.1% of a gelatin hydrolysate to enable the solution to be uniform and stable, finally, cooling the solution to the room temperature, performing degassing with a vacuum degasser, and keeping the solution at the temperature of 95 DEG C for 30 s for short-term high-temperature sterilization. The technology has the benefits that the drink is squeezed out of leftovers of fruits, waste of resources is avoided, the drink is sufficient in nutrition, drinks with different flavors can be processed according to respective taste with the processing technology.

Owner:张桂华

Carboxylated collagen foam stabilizers as well as preparation method and compound modifying method thereof

ActiveCN105944620AGood foam stabilityImprove the environmentTransportation and packagingPeptidesAlkaline proteaseGelatin hydrolysate

The invention relates to carboxylated collagen foam stabilizers as well as a preparation method and a compound modifying method thereof. Waste leather contains a large amount of collagen and can be taken as a biomass resource. The preparation method comprises steps as follows: gelatin is compounded into an aqueous solution, pH is regulated after the gelatin is heated and dissolved, the gelatin is hydrolyzed by alkaline proteases, and a gelatin hydrolysate is obtained; long-chain aliphatic amine and a catalyst are added, and a collagen foam stabilizer is prepared through reaction; water and unreacted long-chain aliphatic amine are extracted out, and a pure collagen foam stabilizer is obtained; sodium dodecyl benzene sulfonate or lauryl sodium sulfate is added, and a compound foam stabilizer is obtained. The waste leather is recycled, a series of collagen foam stabilizers are synthesized according to difference of long-chain aliphatic amine, and the synthesized foam stabilizers have good foaming stability and environment friendliness. Therefore, the series of products have good application prospect.

Owner:SHAANXI UNIV OF SCI & TECH

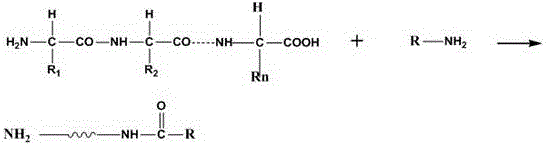

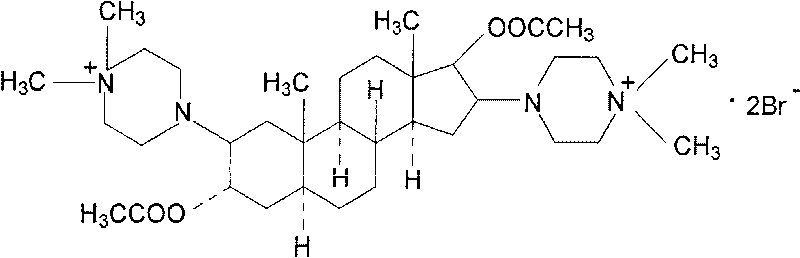

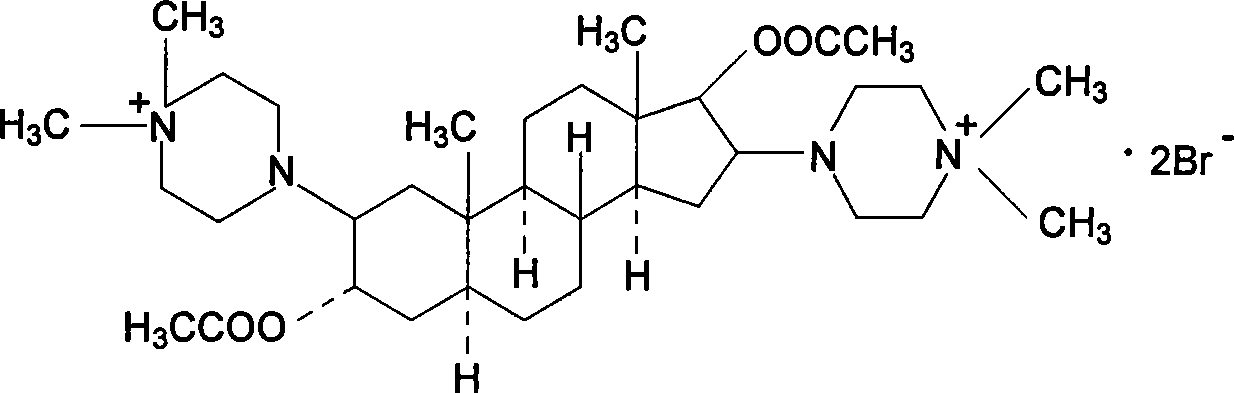

Application of non-depolarizing muscular relaxant in preventing and eliminating facial wrinkles

InactiveCN101019814BOvercoming toxic deficienciesGood moisturizing effectOrganic active ingredientsCosmetic preparationsWrinkle skinGelatin hydrolysate

The present invention discloses the application of non-depolarizing muscular relaxant in preventing and eliminating facial wrinkles and one kind of wrinkle resisting composite containing non-depolarizing muscular relaxant. The wrinkle resisting composite includes effective components, which comprises non-depolarizing muscular relaxant 0.1-1.0 weight portions, hyaluronic acid 0.5-4 weight portionsand gelatin hydrolysate 30-200 weight portions; pharmaceutically acceptable supplementary material. The present invention can prevent and eliminate facial wrinkles effectively.

Owner:沈赞 +2

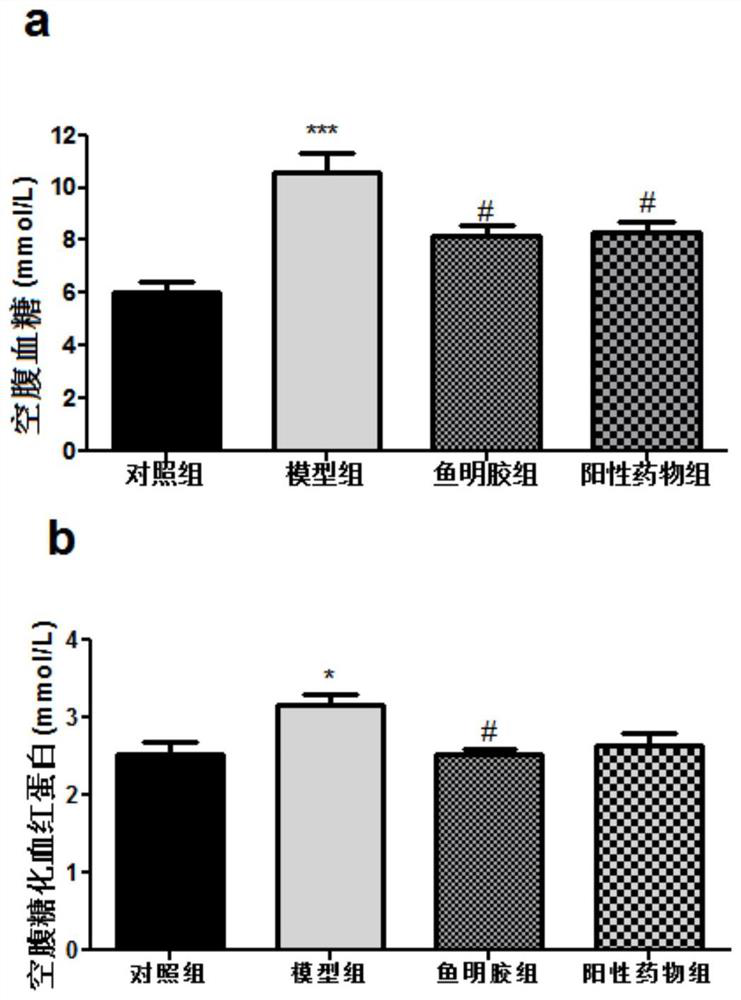

Fish gelatin hydrolysate with oral hypoglycemic activity and application thereof

PendingCN113528604AReduce usageReduce pollutionHydrolysed protein ingredientsMetabolism disorderBiotechnologyNeutral protease

The invention discloses a fish gelatin hydrolysate with oral hypoglycemic activity and an application thereof, and the fish gelatin hydrolysate is mainly prepared by the following method: 1) mixing fish gelatin with papain and neutral protease, adding phellinus linteus ketone and alpha-naphthoflavone at the same time, and performing enzymolysis to form a fish gelatin product A; and 2) mixing the fish gelatin product A with alkaline protease and pepsase, adding herba lycopi flavone and scutellaria baicalensis flavone I at the same time, and continuing enzymolysis to form a fish gelatin final product. Compared with the prior art, the invention provides a novel fish gelatin hydrolysate which has a remarkable oral hypoglycemic effect and can be used for preparing health-care food. Besides, the preparation method is simple and easy to operate, the activity of hydrolase is remarkably promoted by utilizing flavone, the use amount of food-grade hydrolase is remarkably reduced, the hydrolysis reaction time is remarkably shortened, and the production cost is greatly reduced.

Owner:镇江市天益生物科技有限公司

Application of non-depolarizing muscular relaxant in preventing and eliminating facial wrinkles

InactiveCN101019814AOvercoming toxic deficienciesGood moisturizing effectCosmetic preparationsOrganic active ingredientsWrinkle skinFacial skin

The present invention discloses the application of non-depolarizing muscular relaxant in preventing and eliminating facial wrinkles and one kind of wrinkle resisting composite containing non-depolarizing muscular relaxant. The wrinkle resisting composite includes effective components, which comprises non-depolarizing muscular relaxant 0.1-1.0 weight portions, hyaluronic acid 0.5-4 weight portions and gelatin hydrolysate 30-200 weight portions; pharmaceutically acceptable supplementary material. The present invention can prevent and eliminate facial wrinkles effectively.

Owner:沈赞 +2

A method for preparing magnetic adsorption material from animal and plant waste

ActiveCN110548494BHigh porosityLarge specific surface areaOther chemical processesSpecific water treatment objectivesFiberWaste material

The invention discloses a method for preparing a magnetic adsorption material from animal and plant wastes, and solves the problems that an existing magnetic adsorption material is poor in biodegradability and difficult to recycle, and the adsorption performance needs to be improved further. According to the technical scheme, crude fiber plant dregs are used as raw materials for preparation, hollow hydroxyapatite / copper ferrite nanoparticles are prepared through nanofiber crystallization, hydroxyapatite molding, medium-temperature template removal and copper ferrite loading, gelatin hydrolysate is prepared by ingeniously using animal waste gel, and hollow porous hydroxyapatite / copper ferrite nanoparticles are supported through crosslinking. According to the method, the process is simple, reaction conditions are mild, the raw materials are simple and easily available, the production cost is low, the method is easy to operate, the prepared adsorption material has high porosity and largespecific surface area, the adsorption performance of the material is greatly improved, the method has the advantages of repeated utilization and stable adsorption efficiency, complex water pollution can be treated, the recycling reproducibility and biodegradability are good, and the method is environmentally friendly.

Owner:HUBEI UNIV OF TECH

Method for modifying superfine fiber synthetic leather based on amino-terminated hyperbranched polymer

The invention discloses a method for modifying superfine fiber synthetic leather based on an amino-terminated hyperbranched polymer. The amino-terminated hyperbranched polymer is introduced into superfine fiber synthetic leather base cloth subjected to moderate acid hydrolysis through a cross-linking agent capable of crosslinking with amino and carboxyl to increase amino active groups, and then the cross-linking agent is added again to crosslink with gelatin hydrolysate to improve binding capacity of the gelatin hydrolysate and remarkably increase hydrophilic groups inside the base cloth. Simultaneously, a conventional natural leather processing technology is adopted to perform dyeing, grease adding, coating, middling and other operations to modified base cloth, and an imitated natural leather product with performance nearly equal to the natural leather performance is produced. By means of the method, hygienic performance and dyeing performance of products are nearly equal to those of the natural leather, and the products have elasticity, fullness and natural appearance of natural leather products. Simultaneously, the method does not relate to organic solvents, thereby solving the problem that a large number of organic solvents are used in the finishing process after existing superfine fiber synthetic leather is synthetized.

Owner:路亚科消防车辆制造有限公司

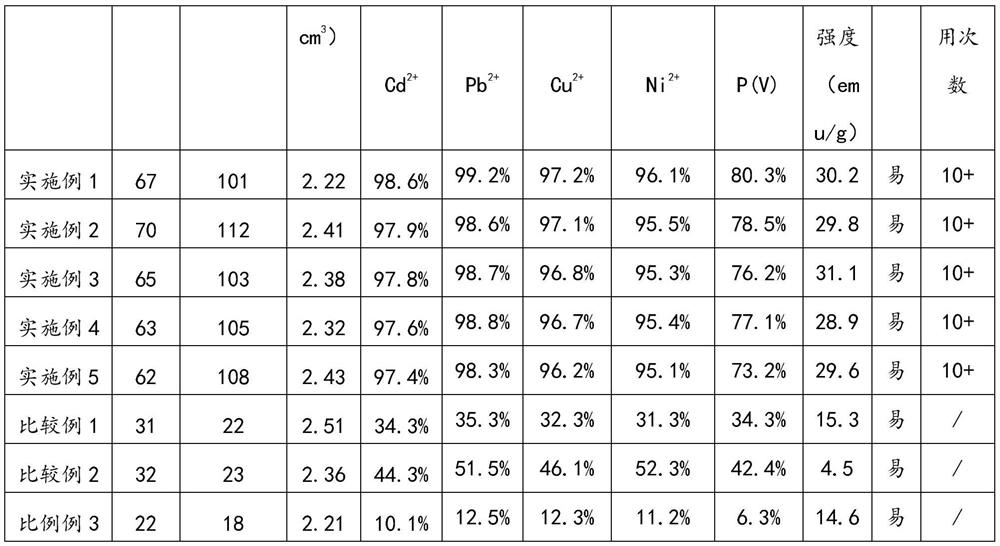

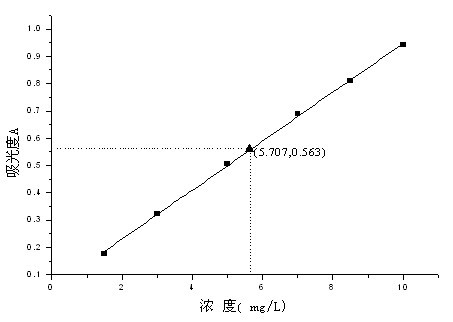

IV type collagenase content measuring method

InactiveCN101846632AAccurate measurementMaterial analysis by observing effect on chemical indicatorGelatin hydrolysateBinding site

The invention discloses an IV type collagenase content measuring method, which relates to a method for measuring the content of IV type collagenase in blood plasma and blood serum of human bodies. The method is characterized in that the IV type collagenase has the gelatin hydrolyzing specific binding site, other matrix metalloproteinase existing in the blood plasma is difficult to hydrolyze the gelatin, TNBS is adopted for developing the color of gelatin hydrolysates, and the quantitative analysis on the specificity of the IV type collagenase in the living blood serum of the blood plasma of the human bodies can be carried out. The invention can accurately and fast measure the IV type collagenase content in the blood plasma or the blood serum of the human bodies.

Owner:HUAZHONG UNIV OF SCI & TECH

Fruit detergent

InactiveCN109749862AKill or inhibit reproductionEasy to removeInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsGelatin hydrolysateChemical residue

The invention relates to the technical field of food detergents, in particular to a fruit detergent. The fruit detergent comprises, by weight, 20-30 parts of alkyl glucoside, 8-12 parts of gelatin hydrolysate, 6-10 parts of sodium carboxymethyl corn starch, 5-9 parts of sodium citrate, 10-20 parts of soybean lecithin, 6-10 parts of table salt, 0.2-0.3 part of bactericides and 30-50 parts of deionized water. According to the technical scheme, the fruit detergent has the advantages that harmful substances such as pesticides and germs on the surfaces of fruits can be effectively removed by the fruit detergent, the fruit detergent in formulas comprises natural detergents, and accordingly people do not need to worry about the problem of chemical residues; the cost can be reduced by natural Chinese herbal medicine and natural plant extraction and purification agents, the fruit detergent is safe and environmentally friendly, the shortcoming of chemical residue phenomena after existing fruitsare cleaned by the traditional detergents can be overcome by the aid of the fruit detergent, and the fruit detergent is free of harm on the skin of people.

Owner:丹阳润富农业技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com