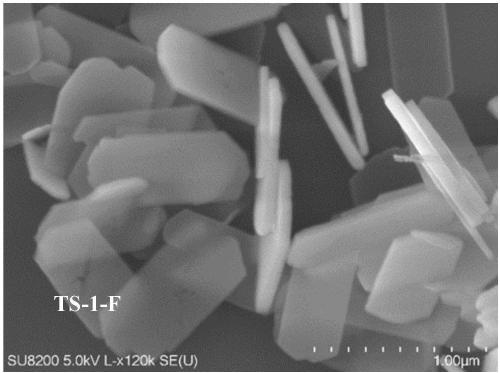

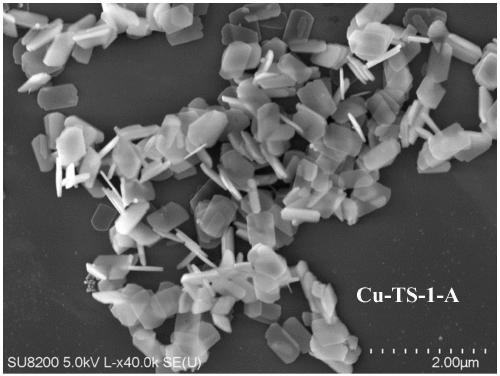

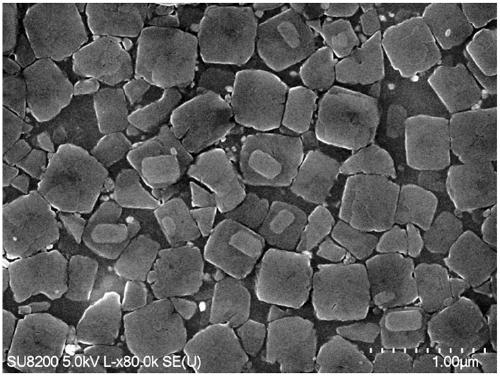

Laminar heteroatom molecular sieve and synthesizing method thereof

A technology of heteroatom molecular sieve and synthesis method, applied in molecular sieve compounds, molecular sieve characteristic silicates, chemical instruments and methods, etc., can solve the problems of large diffusion resistance, difficult solid-liquid separation, and few active centers of microporous molecular sieves, and achieves The effect of inhibiting carbon deposition inactivation, improving diffusion performance, and reducing preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Add 12.1g of methyl orthosilicate, 20g of 25wt% tetrapropylammonium hydroxide aqueous solution, 15g of deionized water, and 1.8g of gelatin into a jacketed three-necked flask, and stir evenly to obtain a mixed solution A; mix the mixed solution A in Hydrolysis at 50°C for 1.5h. Mix 0.47g tetraethyl titanate, 8.1g 25wt% tetrapropylammonium hydroxide aqueous solution, and 15g deionized water, and stir evenly to obtain mixed solution B; hydrolyze mixed solution B at 50°C for 1.5h; mix mixed solution A Mix with mixed solution B, stir evenly, remove alcohol at 90°C for 2 hours, add 0.3g gelatin to obtain mixed solution C, stir mixed solution C at 40°C for 20min, put the mixed solution into a crystallization kettle, and crystallize at 160°C After 72 hours, the crystallized product was washed, dried, and then calcined at 480°C for 5 hours to obtain TS-1, which was numbered TS-1-C.

Embodiment 2

[0048] Add 16.5g of tetrapropylammonium hydroxide aqueous solution, 20g of 25wt% tetrapropylammonium hydroxide solution, 15g of deionized water, 1.8g of gelatin in the jacketed three-necked flask, stir evenly, and obtain the mixed solution A; Hydrolysis at 40°C for 1h. Mix 0.47g of tetraethyl titanate, 8.1g of 25wt% tetrapropylammonium hydroxide aqueous solution, and 15g of deionized water, and stir evenly to obtain a mixed solution B; hydrolyze the mixed solution B at 40°C for 0.5h; Mix A and mixed solution B, stir evenly, remove alcohol at 90°C for 1 hour, add 0.3g gelatin to obtain mixed solution C, stir mixed solution C at 50°C for 15min, put the mixed solution into a crystallization tank, and heat at 160°C After crystallization for 72 hours, the crystallized product was washed, dried, and calcined at 480°C for 5 hours to obtain TS-1, which was designated as TS-1-D.

Embodiment 3

[0050] Add 16.5g tetrapropylammonium hydroxide aqueous solution, 20g 25wt% tetrapropylammonium hydroxide aqueous solution, 15g deionized water, 1.8g gelatin in the three-necked flask with jacket, stir well, obtain mixed solution A; Mixed solution A Hydrolysis at 40 ° C for 2h. Mix 1.45g of tetrabutyl titanate, 8.1g of 25wt% tetrapropylammonium hydroxide aqueous solution, and 15g of deionized water, and stir evenly to obtain a mixed solution B; hydrolyze the mixed solution B at 50°C for 1 hour; mix the mixed solution A and Mix the mixed solution B, stir evenly, remove the alcohol at 80°C for 1 hour, add 0.3g of gelatin to obtain the mixed solution C, stir the mixed solution C at 40°C for 20min, put the mixed solution into a crystallization kettle, and crystallize at 160°C After 72 hours, the crystallized product was washed, dried, and then calcined at 540°C for 6 hours to obtain TS-1, which was numbered TS-1-E.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com