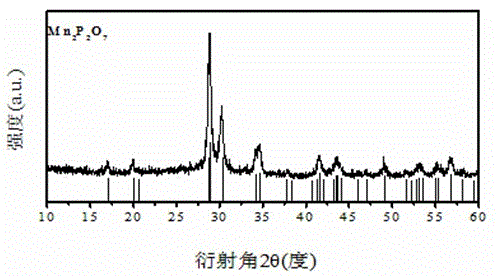

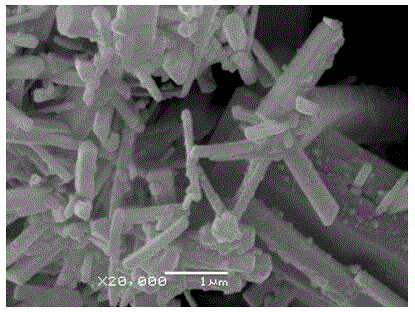

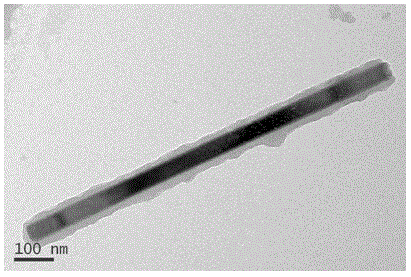

Mn2P2O7 anode material of core-shell structured lithium ion battery and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of increasing the contact area between active materials and electrolyte, affecting the electrochemical performance of materials, and reducing the electrochemical performance of materials. Achieve the effect of improving electrochemical performance, smooth lithium ion deintercalation channel, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Mix 0.005mol disodium manganese edetate and 0.005mol ammonium dihydrogen phosphate, and dissolve them in 100mL deionized water to obtain a mixed solution;

[0027] (2) Adjust the pH value of the mixed solution obtained in step (1) to 3;

[0028] (3) Place the mixed solution after pH adjustment in step (2) in a constant temperature water bath at 60°C, and mechanically stir for 30 hours to form a uniform gel;

[0029] (4) Dry the gel obtained in step (3) in a vacuum drying oven at 60°C for 15 hours to obtain a manganese pyrophosphate precursor;

[0030] (5) Place the manganese pyrophosphate precursor obtained in step (4) in a tubular sintering furnace, sinter at 700°C for 12 hours in an argon atmosphere, and cool naturally to room temperature to obtain coke, a negative electrode material for lithium-ion batteries with a core-shell structure. manganese phosphate.

[0031] After testing, the obtained manganese pyrophosphate, the negative electrode material of the lith...

Embodiment 2

[0034] (1) Mix 0.008mol manganese acetylacetonate and 0.008mol diammonium hydrogen phosphate, and dissolve them in 100mL deionized water to obtain a mixed solution;

[0035] (2) Adjust the pH value of the mixed solution obtained in step (1) to 7;

[0036] (3) Place the mixed solution after pH adjustment in step (2) in a constant temperature water bath at 80°C, and mechanically stir for 15 hours to form a uniform gel;

[0037] (4) Dry the gel obtained in step (3) in a vacuum oven at 100°C for 5 hours to obtain a manganese pyrophosphate precursor;

[0038] (5) Place the manganese pyrophosphate precursor obtained in step (4) in a tubular sintering furnace, sinter at 600°C for 8 hours in a nitrogen atmosphere, and cool naturally to room temperature to obtain the core-shell structure lithium-ion battery positive and negative materials Manganese pyrophosphate.

[0039]After testing, the manganese pyrophosphate anode material of the obtained core-shell structure lithium ion battery...

Embodiment 3

[0042] (1) Mix 0.05mol disodium manganese EDTA and 0.05mol ammonium phosphate, and dissolve them in 1000mL deionized water to obtain a mixed solution;

[0043] (2) Adjust the pH value of the mixed solution obtained in step (1) to 5;

[0044] (3) Place the mixed solution after pH adjustment in step (2) in a constant temperature water bath at 90°C, and mechanically stir for 10 hours to form a uniform gel;

[0045] (4) Place the gel obtained in step (3) in a vacuum oven at 80°C and dry for 12 hours to obtain the manganese pyrophosphate precursor;

[0046] (5) Place the manganese pyrophosphate precursor obtained in step (4) in a tubular sintering furnace, sinter at 400°C for 12 hours in an argon atmosphere, and cool naturally to room temperature to obtain coke, a negative electrode material for lithium-ion batteries with a core-shell structure. manganese phosphate.

[0047] After testing, the obtained manganese pyrophosphate, the negative electrode material of the lithium-ion ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com