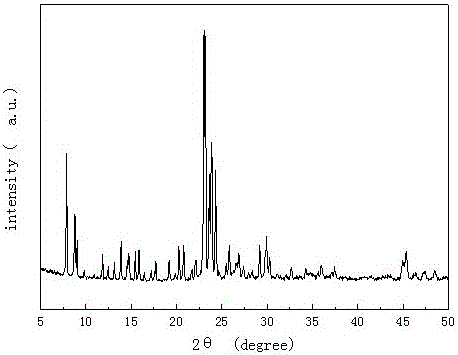

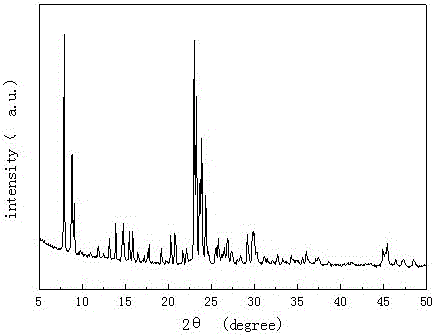

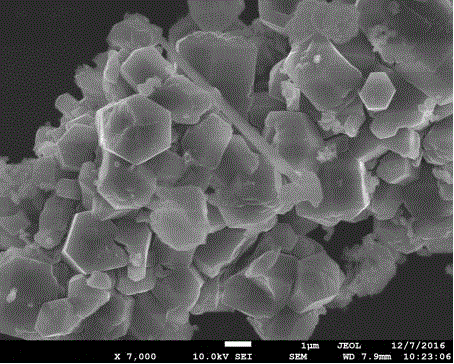

Synthesis method of integral hierarchical-pore ZSM-5 molecular sieve

A synthesis method, ZSM-5 technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of reduced content of active components of catalysts, blockage of molecular sieve channels, complex operating procedures, etc., to achieve short Diffusion path, reduction of preparation cost, effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]A kind of synthetic method of monolithic hierarchical porous ZSM-5 molecular sieve, comprises the following steps:

[0037] (1) Add sodium metaaluminate, sodium hydroxide, tetrapropylammonium bromide (TPABr) and deionized water into the beaker and stir evenly, then gradually add sodium silicate into the beaker, stir vigorously to form a uniform gel, pour Put it into a polytetrafluoroethylene-lined stainless steel reactor for crystallization at 160°C for 3 days, and the molar composition of the product obtained (the aluminum source is represented by Al 2 o 3 In terms of sodium hydroxide as Na 2 Calculated as O, silicon source as SiO 2 Count) is n (Na 2 O) :n(SiO 2 ): n(TPABr):n(Al 2 o 3 ):n(H 2 O) = 10.5: 20: 20: 1: 5000;

[0038] (2) The product obtained in step (1) was repeatedly washed with deionized water until the pH value was close to neutral, and dried at 100°C to obtain a ZSM-5 molecular sieve;

[0039] (3) The ZSM-5 molecular sieve was calcined at 550° C...

Embodiment 2

[0041] A kind of synthetic method of monolithic hierarchical porous ZSM-5 molecular sieve, comprises the following steps:

[0042] (1) Add sodium metaaluminate, sodium hydroxide, tetrapropylammonium bromide (TPABr) and deionized water into the beaker and stir evenly, then gradually add tetraethyl orthosilicate into the beaker, stir vigorously to form a uniform gel , poured into a polytetrafluoroethylene-lined stainless steel reactor for crystallization at 150°C for 7 days, the molar composition of the product obtained (the aluminum source is represented by Al 2 o 3 In terms of sodium hydroxide as Na 2 Calculated as O, silicon source as SiO 2 Count) is n (Na 2 O):n(SiO 2 ): n(TPABr) :n(Al 2 o 3 ):n(H 2 O) = 10: 50: 20: 1: 1000;

[0043] (2) The product obtained in step (1) was repeatedly washed with deionized water until the pH value was close to neutral, and dried at 100°C to obtain a ZSM-5 molecular sieve;

[0044] (3) The ZSM-5 molecular sieve was calcined at 500° C...

Embodiment 3

[0046] A kind of synthetic method of monolithic hierarchical porous ZSM-5 molecular sieve, comprises the following steps:

[0047] (1) Add aluminum sulfate, sodium hydroxide, tetrapropylammonium hydroxide (TPAOH) and deionized water into a beaker and stir evenly, then gradually add silica sol into the beaker, stir vigorously to form a uniform gel, pour poly Crystallization at 150-180°C for 2-7 days in a stainless steel reactor lined with vinyl fluoride, the molar composition of the obtained product (the aluminum source is Al 2 o 3 In terms of sodium hydroxide as Na 2 Calculated as O, silicon source as SiO 2 Count) is n (Na 2 O) :n(SiO 2 ) :n(TPAOH) :n(Al 2 o 3 ):n(H 2 O) = 15: 100: 10: 1: 1500;

[0048] (2) The product obtained in step (1) was repeatedly washed with deionized water until the pH value was close to neutral, and dried at 100°C to obtain a ZSM-5 molecular sieve;

[0049] (3) The ZSM-5 molecular sieve was calcined at 650° C. for 4 hours in an oxygen atmosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com