A method for preparing magnetic adsorption material from animal and plant waste

A technology for magnetic adsorption materials, animals and plants, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc. The effects of biodegradability, high internal structure retention, and strength regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

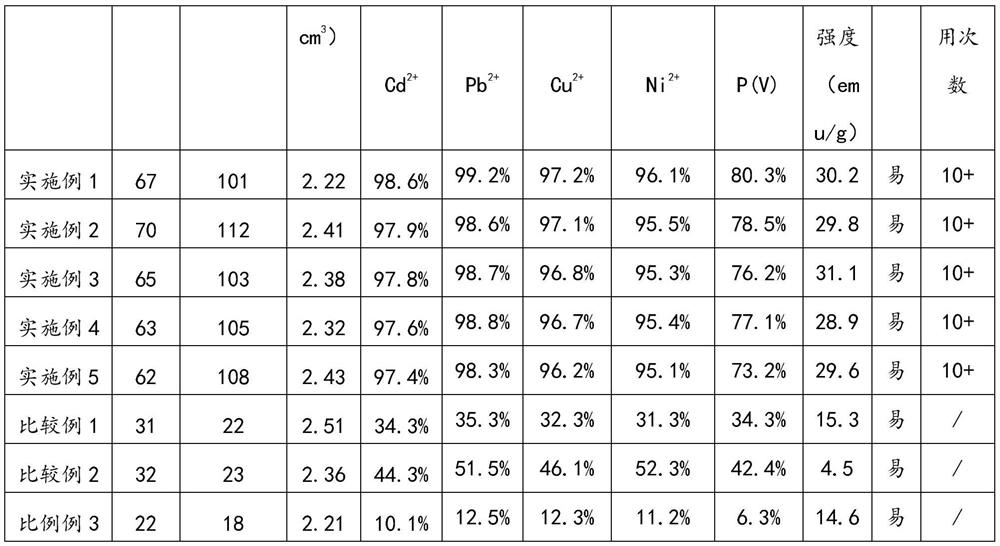

Examples

Embodiment 1

[0026] Step 1. The bagasse is sheared and pulped (the ratio of bagasse to water is 1:10), and 100 parts by weight of the crude fiber slurry obtained by filtering is added to 100 parts by weight of 64% sulfuric acid aqueous solution, and processed by mechanical stirring for 2 hours. Cellulose nanocrystals were obtained by centrifugal washing and separation.

[0027] Step 2. 20 parts by weight of cellulose nanocrystals are dispersed in 100 parts by weight, 4 parts by weight of surfactants and 2 parts by weight of pore-forming agents and 5 parts by weight of calcium acetate, mechanically stirred for 2 hours, and added 5 parts by weight of concentration of 10% sodium phosphate aqueous solution, mechanical stirring, centrifugal washing, separation and drying to obtain a hydroxyapatite fiber composite material, and continuous heat treatment for 3 hours in an oxygen atmosphere of 180 ° C, and collecting powder to obtain hollow hydroxyapatite.

[0028] Step 3. Disperse 40 parts by wei...

Embodiment 2

[0031] Step 1. The bagasse is sheared and pulped (the ratio of bagasse to water is 1:10), and 200 parts by weight of the crude fiber slurry obtained by filtering is added to 100 parts by weight of 64% sulfuric acid aqueous solution, and processed by mechanical stirring for 4 hours. Cellulose nanocrystals were obtained by centrifugal washing and separation.

[0032] Step 2. 40 parts by weight of cellulose nanocrystals are dispersed in 100 parts by weight, 6 parts by weight of surfactants and 4 parts by weight of pore-forming agents and 10 parts by weight of calcium acetate, mechanically stirred for 6 hours, and added 10 parts by weight of concentration of 10% sodium phosphate aqueous solution, mechanical stirring, centrifugal washing, separation and drying to obtain a hydroxyapatite fiber composite material, in an oxygen atmosphere of 200 ° C, continuous heat treatment for 5 hours, collecting powder to obtain hollow hydroxyapatite.

[0033] Step 3. Disperse 60 parts by weight o...

Embodiment 3

[0036] Step 1. The bagasse is sheared and pulped (the ratio of bagasse to water is 1:10), and 100 parts by weight of the crude fiber slurry obtained by filtering is added to 100 parts by weight of 64% sulfuric acid aqueous solution, and processed by mechanical stirring for 4 hours. Cellulose nanocrystals were obtained by centrifugal washing and separation.

[0037]Step 2. 20 parts by weight of cellulose nanocrystals are dispersed in 100 parts by weight, 6 parts by weight of surfactants and 2 parts by weight of pore-forming agents and 5 parts by weight of calcium acetate, mechanically stirred for 2 hours, and add 10 parts by weight of concentration of 10% sodium phosphate aqueous solution, mechanical stirring, centrifugal washing, separation and drying to obtain a hydroxyapatite fiber composite material, in an oxygen atmosphere of 190 ° C, continuous heat treatment for 4 hours, collecting powder to obtain hollow hydroxyapatite.

[0038] Step 3. Disperse 40 parts by weight of ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com