Amoxicillin soluble powder and preparation method thereof

An amoxicillin and soluble technology, which is applied in the field of amoxicillin soluble powder and its preparation, can solve the problems of difficulty in the preparation of sustained-release preparations, affect drug efficacy, and slow release, and achieve improved physical and chemical stability and long-lasting therapeutic effects , the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

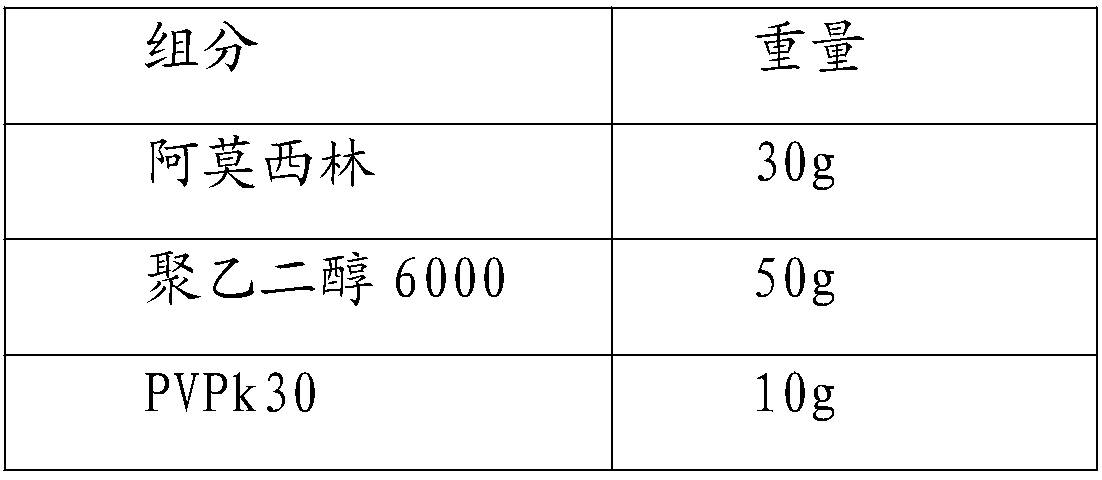

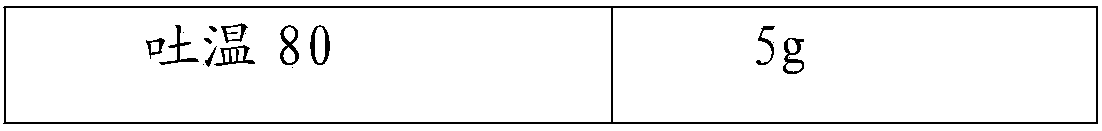

[0057] Embodiment 1 prepares soluble powder with gelatin hydrolyzate of average molecular weight 1500Da-3000Da

[0058]

[0059] Pass amoxicillin and sorbitol through a 80-mesh sieve, mix evenly to obtain a mixed powder; add gelatin hydrolyzate to water to prepare an aqueous solution, then add it to the mixed powder, stir, granulate, dry, granulate, and pack, that is have to.

[0060] 1. Water solubility test and aqueous solution stability test

[0061] Take 1 g of the soluble powder of Comparative Examples 1-6 and Example 1, calculated as amoxicillin, place it in 150 ml of water with a temperature of 25°C ± 2°C, shake it for 2 minutes, observe the solution after standing for 30 minutes, and take a sample for determination content (recorded as 0h content); then place each solution at 40°C for 4h, 12h and 24h, observe and record the solution, and take a sample to measure the content, and calculate the loss rate by comparing with the 0-hour content. The results are shown in th...

Embodiment 2

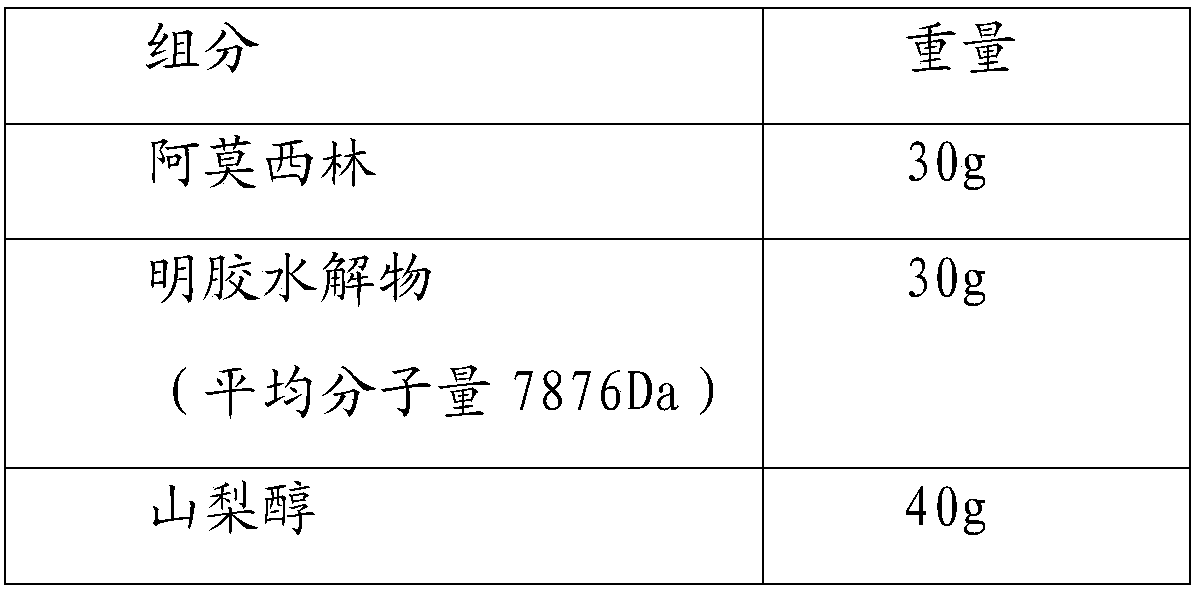

[0083] Embodiment 2 prepares the gelatin hydrolyzate of average molecular weight 1500Da-3000Da

[0084] Add 1kg type A gelatin to 2kg water, heat to 55°C to dissolve, adjust the pH value of the gelatin aqueous solution to 6.5 with disodium hydrogen phosphate solution, heat to 60°C, add 0.1% w / w trypsin to the gelatin aqueous solution and stir for 2 hours Finally, 0.1% w / w Bacillus licheniformis was added to the solution, and after reacting for 2 hours, the solution was heated to 90° C. to kill enzymes, filtered, concentrated, and dried to obtain gelatin hydrolyzate. Its average molecular weight was determined to be 2488Da.

Embodiment 3

[0085] Embodiment 3 prepares the gelatin hydrolyzate of average molecular weight 1500Da-2000Da

[0086] Add 1kg type B gelatin to 2kg water, heat to 55°C to dissolve, adjust the pH value of the gelatin aqueous solution to 6.5 with disodium hydrogen phosphate solution, heat to 60°C, add 0.1% w / w trypsin to the gelatin aqueous solution and stir for 3 hours Finally, add 0.1% w / w Bacillus licheniformis to the solution, react for 3 hours, add 0.08% w / w protease from Aspergillus niger fermentation to the solution, react for 1.5 hours, heat the solution to 90°C to kill the enzyme , filtered, concentrated, and dried to obtain gelatin hydrolyzate. Its average molecular weight was determined to be 1623Da.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com