Carboxylated collagen foam stabilizers as well as preparation method and compound modifying method thereof

A technology of collagenization and collagen, applied in the field of carboxylated collagen foam stabilizer and its preparation, to achieve good application prospects, good foam stability and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

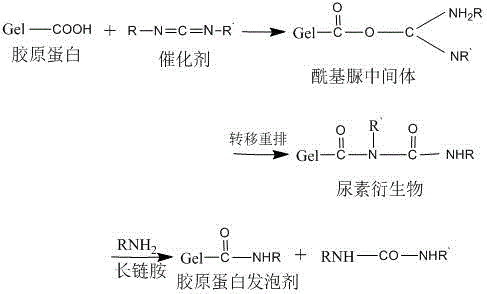

[0053] The preparation method and compound modification method of the above-mentioned carboxylated collagen foam stabilizer have the following reaction route:

[0054]

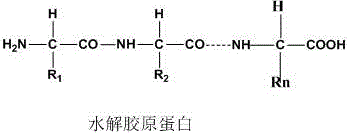

[0055] Hydrolyzed collagen has the following structure:

[0056]

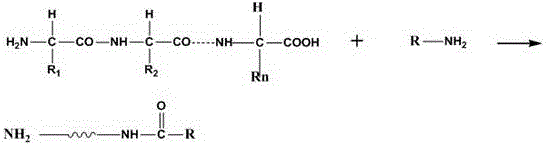

[0057] Hydrolyzed collagen is amphiphilic and is a surface active substance, but its hydrophilicity is too strong, and its foaming and foam stabilization performance is not good, so it needs to be modified, and its hydrophobicity can be enhanced by adding hydrophobic groups surface activity. The hydrophobic group connected in the present invention is a long-chain aliphatic amine group, and the structural formula is as follows:

[0058]

Embodiment 1

[0060] Step 1: Preparation of hydrolyzed gelatin:

[0061] Make 20g dry weight of gelatin into an aqueous solution with a mass fraction of 10%, raise the temperature to 50°C, adjust the pH to 9 after the gelatin is completely dissolved, hydrolyze the gelatin with alkaline protease of 0.5% gelatin dry weight, react for 4 hours, and raise the temperature Heat to 90°C to inactivate the enzyme, and filter to obtain the hydrolyzed gelatin solution;

[0062] Step 2: Preparation of collagen foam stabilizer:

[0063] Add 3g of long-chain fatty amine to the hydrolyzed gelatin solution, and then add 1g of catalyst, stir and react at 30°C for 1h to prepare collagen foam stabilizer.

[0064] Step 3: Purification of collagen foam stabilizer:

[0065] After the reaction, use a rotary evaporator to remove water and unreacted long-chain fatty amines to obtain pure collagen foam stabilizer.

[0066] Step 4: Preparation of collagen compound modified foam stabilizer:

[0067] Add 0.2 g of so...

Embodiment 2

[0071] Step 1: Preparation of hydrolyzed gelatin:

[0072] Make 20g of dry weight gelatin into an aqueous solution with a mass fraction of 20%, raise the temperature to 50°C, adjust the pH to 8 after the gelatin is completely dissolved, and hydrolyze the gelatin with alkaline protease with a dry weight of 1.5% of the gelatin, and react for 2.5 hours. Raise the temperature to 90°C to inactivate the enzyme, and filter to obtain the hydrolyzed gelatin solution;

[0073] Step 2: Preparation of collagen foam stabilizer:

[0074] Add 6g of long-chain fatty amine to hydrolyzed gelatin solution, then add 3g of catalyst, stir and react at 40°C for 3h, and prepare collagen foam stabilizer.

[0075] Step 3: Purification of collagen foam stabilizer:

[0076] After the reaction, use a rotary evaporator to remove water and unreacted long-chain fatty amines to obtain pure collagen foam stabilizer.

[0077] Step 4: Preparation of collagen compound modified foam stabilizer:

[0078] Add 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com