Preparation method of waterborne polyurethane (WPU)/collagen/hydroxyapatite (HAP) composite material

A water-based polyurethane, hydroxyapatite technology, applied in the fields of medical science, prosthesis, tissue regeneration, etc., can solve the problems of difficulty in balancing mechanical properties, biological functions and biodegradation properties, lack of osteoinductive activity, and poor plasticity. , to achieve the effects of controllable mechanical processability, good biocompatibility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

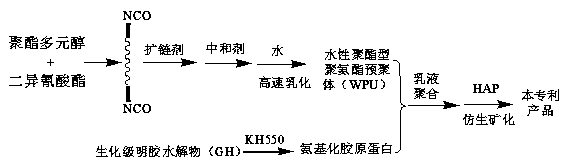

[0048] Example 1, a method for preparing a water-based polyurethane / collagen / hydroxyapatite composite material, the material is prepared using a glass three-necked flask, equipped with vacuum dehydration, heating and cooling, condensation reflux, constant pressure dripping device, including the following steps :

[0049] (1) Weigh 50 g of polyethylene adipate diol (molecular weight: 2000), vacuum dehydrate at 110°C for 1~2 h, cool down to 60°C, add 45 g of diphenylmethane diisocyanate to react 1 h, be warming up to 82 DEG C, be incubated 1 h and obtain prepolymer;

[0050](2) In step (1), the temperature of the prepolymer was lowered to 60°C, and 5 g of dimethylolpropionic acid was added for chain extension, and reacted for 1 h, and then 8 g of diethylene glycol was added to the system for Chain extension, after reacting for 30 minutes, raise the temperature to 82°C and keep it warm for 2-3 hours until -NCO is close to the theoretical value (detected by di-n-butylamine method...

Embodiment 2

[0055] Embodiment 2, a kind of preparation method of aqueous polyurethane / collagen protein / hydroxyapatite composite material, comprises the following steps:

[0056] (1) Weigh 50 g of polytrimethylene adipate diol (molecular weight 2000), vacuum dehydrate at 105°C for 1~2 h, cool down to 60°C, add 30 g of toluene diisocyanate, react for 1 h, and heat up to 82 ° C, incubated for 1 h to obtain the prepolymer;

[0057] (2) Cool the prepolymer to 60°C in step (1), add 5 g of dimethylolpropionic acid for chain extension, react for 1 h, add 3 g of propylene glycol to the system for chain extension, and react for 30 min, Heat up to 80°C, keep warm for 2-3 hours;

[0058] (3) Cool the product in step (2) to 50°C, add 3.5 g of triethylamine for neutralization, and add an appropriate amount of acetone to adjust the viscosity. After being cooled to room temperature, add 5 DEG C of deionized water 1100r / min and stir for 5 min to obtain an aqueous polyurethane prepolymer emulsion;

[00...

Embodiment 3

[0062] Embodiment 3, a kind of preparation method of aqueous polyurethane / collagen protein / hydroxyapatite composite material, comprises the following steps:

[0063] (1) Weigh 40 g isophorone diisocyanate, 50 g polybutylene adipate diol (molecular weight 2000) after vacuum dehydration, 1~2 drops of dibutyltin dilaurate catalyst, at 65°C Reaction 1 h, be warming up to 80 ℃, insulation 1~2 h obtains prepolymer;

[0064] (2) Add 6 g of dihydroxybutyric acid to the prepolymer in step (1) for chain extension, react at 60°C for 1 h, add 7 g of diethylene glycol to the system for chain extension, and keep warm at 60°C for 1 hour h, be warming up to 80 DEG C, react 2~3 h;

[0065] (3) Cool the product in step (2) to 50°C, add 4 g of triethylamine for neutralization, and adjust the viscosity with an appropriate amount of acetone. After being cooled to room temperature, add 5 DEG C of deionized water 1200r / min and stir for 5 min to obtain an aqueous polyurethane prepolymer emulsion; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com