Enzyme preparation for instant noodle and method of producing instant noodle

A manufacturing method and technology for instant noodles, which are applied in the directions of biochemical equipment and methods, enzymes, applications, etc., can solve the problems that transglutaminase cannot further use instant noodles and are difficult to use, and achieve improved modification effect, hardness and viscosity balance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

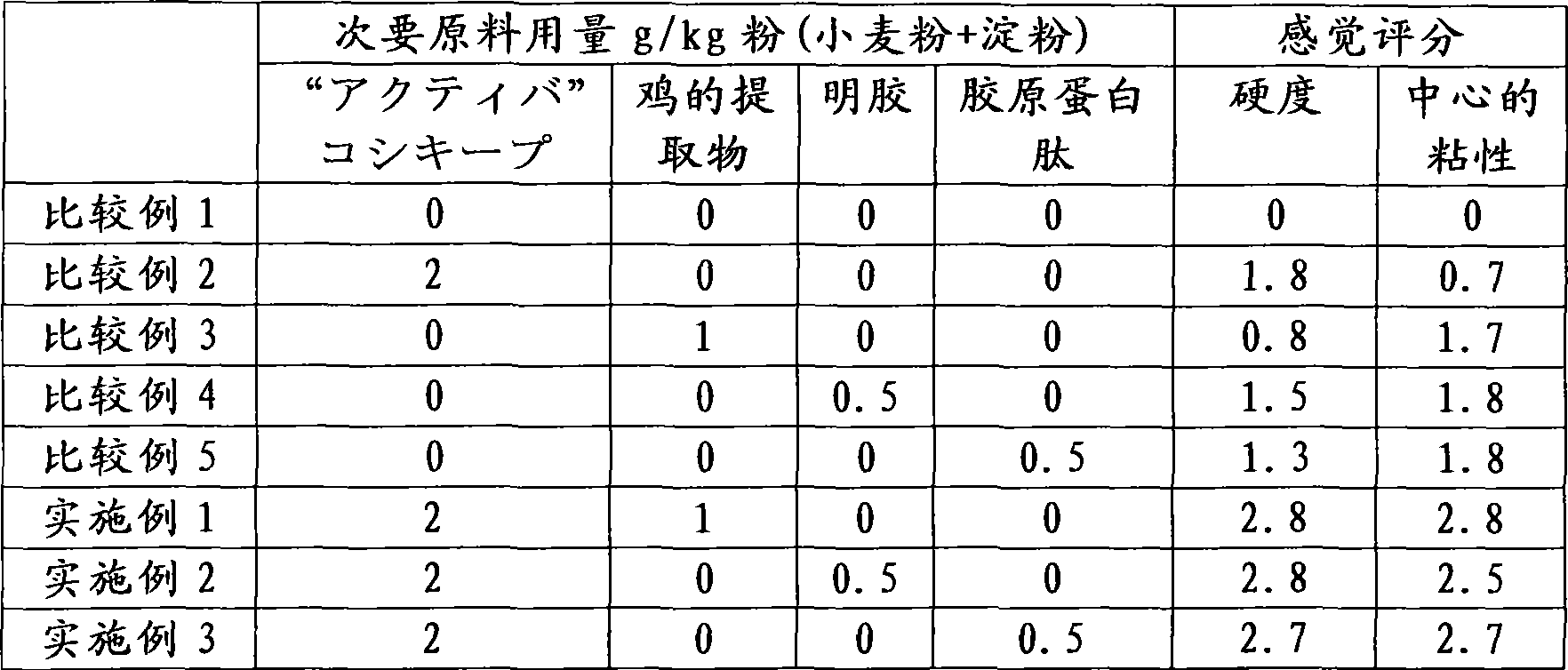

Examples

Embodiment 1

[0024] Add 850 g of quasi-strong wheat flour (trade name: Special Numberone, manufactured by Nissin Milling Co., Ltd.), 150 g of tapioca starch (trade name: Matsutani Sakura, manufactured by Matsutani Chemical Co., Ltd.) in a vacuum mixer, and mix for 2 minutes. In 340g of water, dissolve 15g of salt, 2g of alkaline water preparation (trade name: alkaline water X, manufactured by Nippon Koroid Corporation), "Actiba" Koshiki-pu (transglutaminase activity is 25U / g, manufactured by Ajinomoto Corporation), 1 g of chicken extract (trade name: Chicken AO, derived from chicken bones, hot water extraction, 53% soluble solids concentration, manufactured by Ajinomoto Co.) was added to a vacuum mixer and mixed for 15 minutes, then allowed to stand for 10 minutes. minute. The obtained disheveled dough (raw ground) was poured into the dough in portions according to the usual method using a noodle making machine (manufactured by Fuji Seisakusho Co., Ltd.), compounded, rolled, and prepared s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com