Novel vertical shaft excavating vehicle

A new type of technology for shafts, applied in waterway systems, water supply devices, buildings, etc., can solve problems such as shaft blockage, inability to dredging shafts, and inability to achieve complete dredging of drainage pipe networks. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

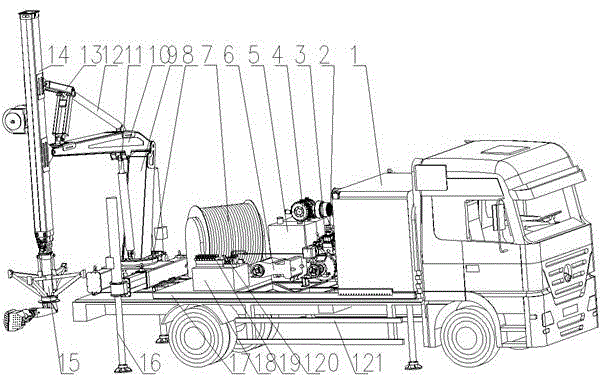

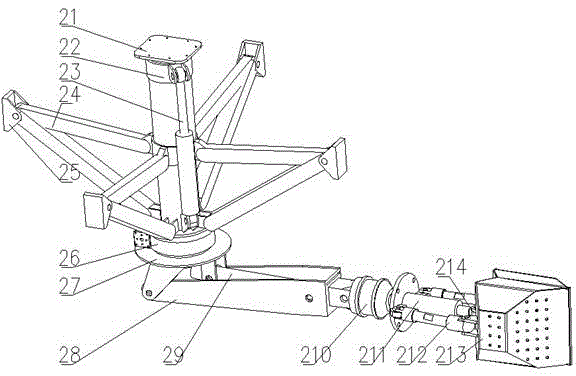

[0029] Such as figure 1 as shown in figure 1 As shown, the shaft excavation vehicle with high-pressure water spraying device of the present invention includes automobile chassis 121, power and heat dissipation system, underframe 17 and outrigger system, hydraulic pressure and electrical control system, luffing mechanism, telescopic arm assembly 14 , Bending grab mechanism 15, high-pressure water spraying device.

[0030] The automobile chassis 121 is a standard chassis, possesses self-maneuvering ability, and satisfies various relevant provisions made in my country's road traffic regulations.

[0031] The power and heat dissipation system is composed of a diesel engine 3, a radiator 2, and a hydraulic pump 4. The hydraulic pump 4 takes power from the diesel engine 3 to provide pressure oil for each actuator of the hydraulic system.

[0032...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com