Oil cylinder reversing and volume speed adjusting hydraulic system

A technology of volumetric speed regulation and hydraulic system, which is applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., and can solve the space required by its own weight and layout. The shape and weight of the system have great influence on reliability and easy maintenance. Reduced performance, system shape and weight increase, etc., to achieve the effect of small weight and layout occupied, reduced overall shape and weight, and easy layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation, features and effects of a cylinder reversing and volumetric speed regulation hydraulic system proposed according to the patent of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

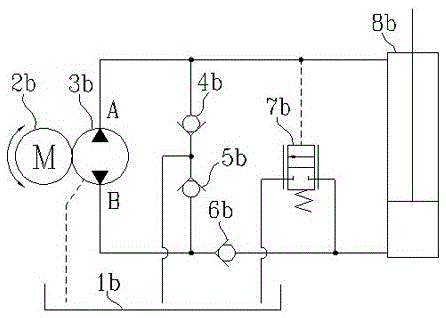

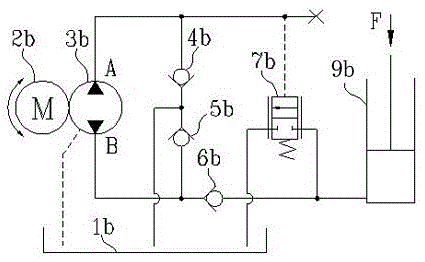

[0037] see figure 2 , a hydraulic system for oil cylinder reversing and volumetric speed regulation, using a semi-open and semi-closed hydraulic circuit, including a prime mover 2b that can rotate in both directions and can be adjusted in speed, and a two-way rotary hydraulic pump 3b, and the two-way rotary hydraulic pump 3b sucks oil from the oil tank B1b , The oil inlet and outlet ports of the bidirectional rotary hydraulic pump 3b are respectively provided with a one-way valve A4b and a one-way valve B5b; one side of the two-way rotary hydraulic pump 3b is connected to the rod chamber of the double-acting cylinder 8b, and the other side of the oil port It is connected to the rodles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com