Mutative scale-based high-precision optical three-dimensional measurement method

A three-dimensional measurement, high-precision technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of complex splicing, slow splicing of multiple pieces, sparse point clouds, etc., to achieve a simple system calibration process, and the freedom of scanning methods. Good, dense point cloud effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

[0034] The variable scale-based high-precision optical three-dimensional measurement method of the present invention includes the following steps:

[0035] Step 1: Build a binocular vision measurement system, select a focal length lens with a large field of view, and perform system calibration on the binocular vision measurement system;

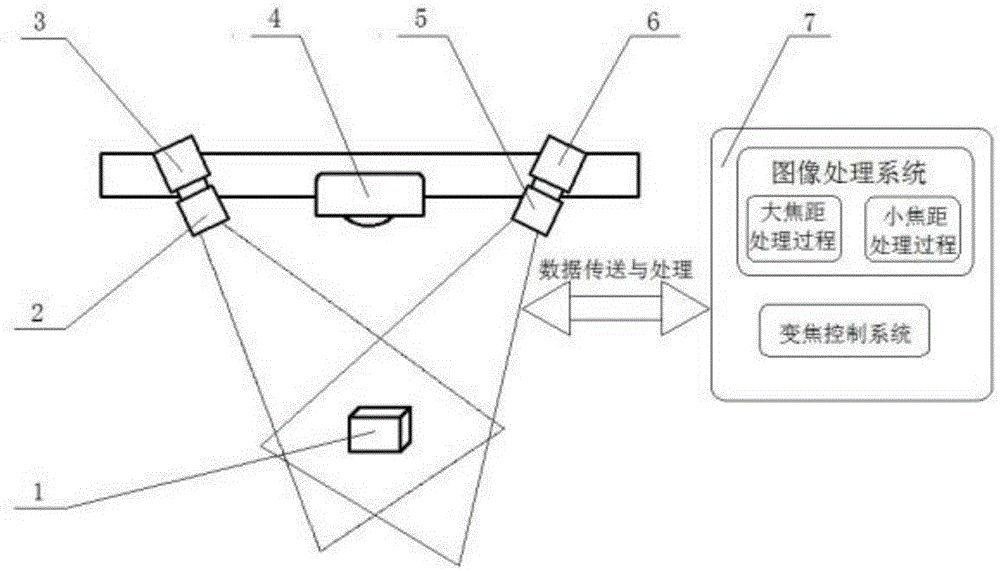

[0036] refer to figure 1 As shown, the binocular vision measurement system mainly includes: object to be measured 1, first camera lens 2, first CCD camera 3, projector 4, second camera lens 5, second CCD camera 6, computer image processing Control system 7, the computer image processing control system 7 includes: an image processing system and a zoom contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com