Wood sign manufacturing method

A production method and signage technology, applied in the directions of marking, instruments, display devices, etc., can solve the problems of single process expression, easy to fade, easy to deform, etc., and achieve the effect of low fading rate and optimized process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

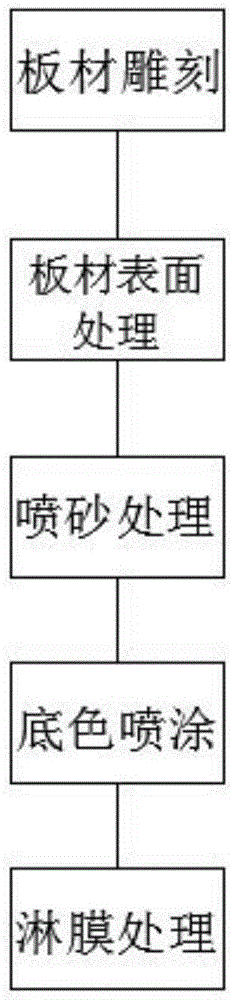

Image

Examples

Embodiment 1

[0022] A kind of wooden sign making method, A. Timber selection and processing: select the dry cedar plank for use, use the numerical control machine tool equipment to carve the outer contour of the plank that thickness is 3cm according to design requirement. Use a p200 mesh sander to smooth and polish the surface of the board. B. Signage sandblasting treatment: use engraving equipment to make the text or pattern to be displayed on the signage into a sandblasting baffle model; the specific engraving parameters are: engraving speed 55mm / s, engraving knife pressure 60G; positioning accuracy is less than 0.1mm. Paste the carved baffle model flatly on the wooden board. Use sandblasting equipment to carry out sandblasting on the wooden boards pasted with the baffle model; sandblasting steps: use fine sand with a diameter of 0.1mm for sandblasting at a rate of 10kg / cm 2 Pressure sandblasts the planks. The sandblasting speed is controlled at 5cm according to the pressure 2 / min. ...

Embodiment 2

[0024] A kind of wooden signboard manufacturing method, A. Timber selection and processing: select the dry cedar plank for use, use the numerical control machine tool equipment to carve the outer contour of the plank that thickness is 6cm according to design requirement. Use a p200 mesh sander to smooth and polish the surface of the board. B. Signage sandblasting treatment: use engraving equipment to make the text or pattern to be displayed on the signage into a sandblasting baffle model; the specific engraving parameters are: engraving speed 60mm / s, engraving knife pressure 70G; positioning accuracy is less than 0.1mm. Paste the carved baffle model flatly on the wooden board. Use sandblasting equipment to carry out sandblasting on the wooden boards pasted with the baffle model; sandblasting steps: use fine sand with a diameter of 0.8mm for sandblasting at a rate of 10kg / cm 2 Pressure sandblasts the planks. The sandblasting speed is controlled at 25cm according to the pressu...

Embodiment 3

[0026] A kind of wooden sign making method, A. Timber selection and processing: select the dry cedar plank for use, use the numerical control machine tool equipment to carve the outer contour of the plank that thickness is 4cm according to design requirement. Use a p200 mesh sander to smooth and polish the surface of the board. B. Signage sandblasting: Use engraving equipment to make the text or pattern to be displayed on the signage into a sandblasting baffle model; the specific engraving parameters are: engraving speed 57mm / s, knife pressure 65G; positioning accuracy is less than 0.1mm. Paste the carved baffle model flatly on the wooden board. Use sandblasting equipment to carry out sandblasting on the wooden boards pasted with the baffle model; sandblasting steps: use fine sand with a diameter of 0.5mm for sandblasting at 8kg / cm 2 Pressure sandblasts the planks. The sandblasting speed is controlled at 15cm according to the pressure 2 / min. C. Coloring of the sign: use a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com