Porous flame holder for low nox combustion

A flame holding and burner technology, used in burners, gas fuel burners, combustion chambers, etc., can solve the problems of energy efficiency loss, consumption of harmful substances, and high installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following Detailed Description, reference is made to the accompanying drawings which form a part hereof. In the drawings, similar symbols typically identify similar components, unless context dictates otherwise. The exemplary embodiments described in the detailed description, drawings, and claims are not intended to be limiting. Other embodiments may be utilized, and other changes may be made, without departing from the spirit or scope of the subject matter described herein.

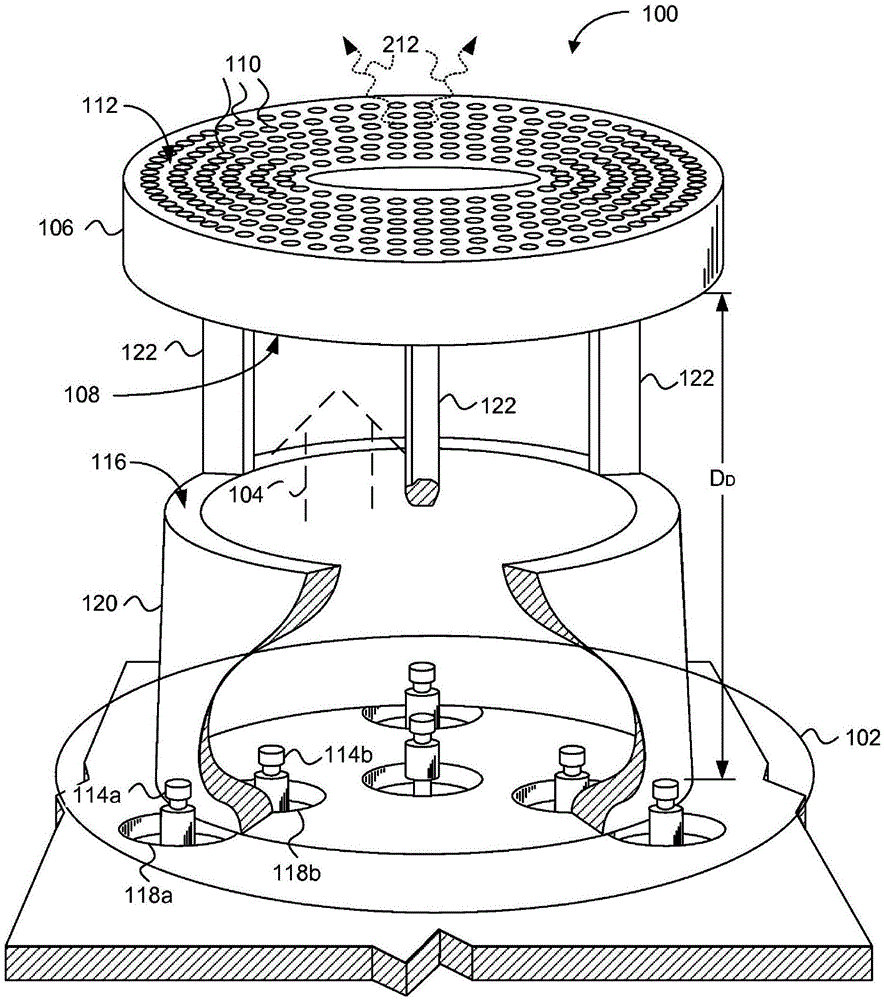

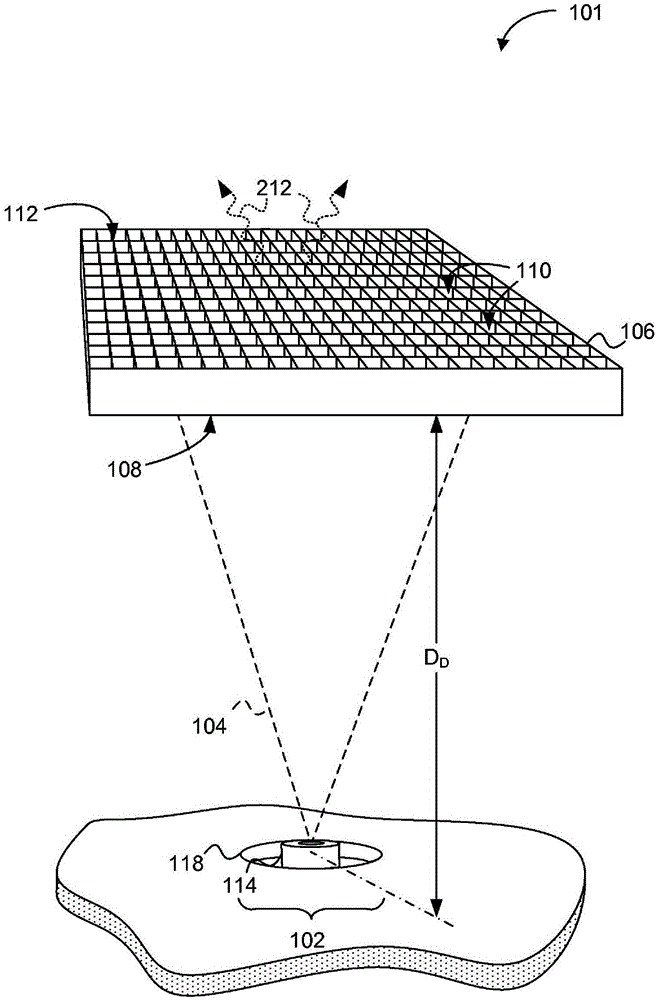

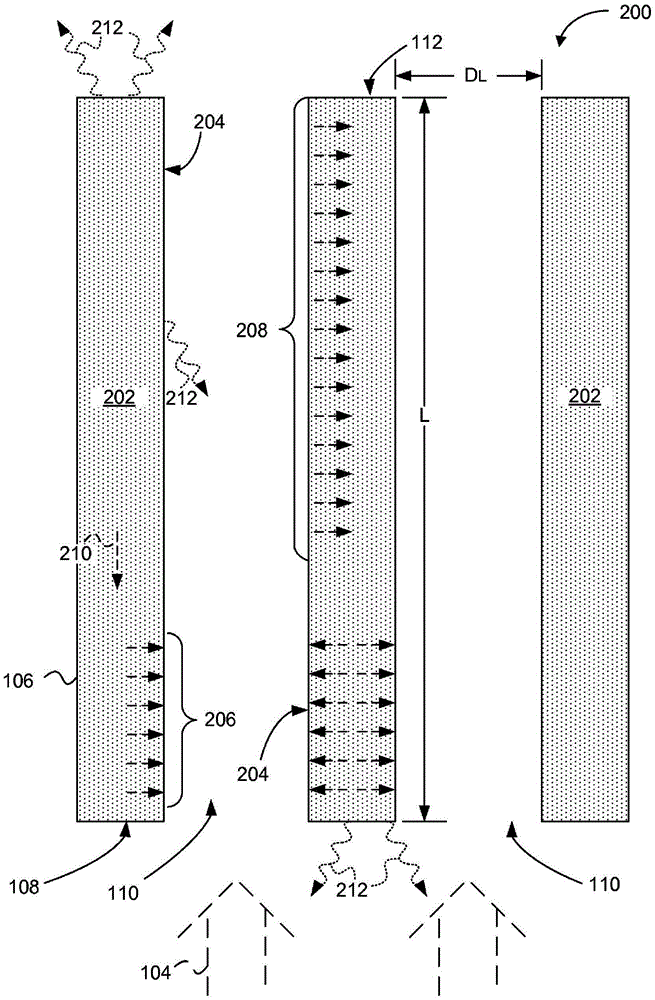

[0020] Figure 1A is a schematic diagram of a combustor 100 according to an embodiment. Figure 1B is a schematic diagram of a combustor 101 according to another embodiment. see Figure 1A and Figure 1B , the combustor 100, 101 includes a fuel nozzle assembly 102 configured to output a gas mixture 104 including fuel and an oxidant. Porous flame holder 106 is aligned to receive gas mixture 104 at upstream surface 108 . Porous flame holder 106 defines a plurality of gas channels 110 , e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com