Self-adaption clamping device for rock cutting machine

A clamping device and self-adaptive technology, used in sampling devices, stone processing equipment, work accessories, etc., can solve the problems of sample preparation failure, sample stress concentration, cracking and other problems, so as to improve the clamping effect and improve the cutting accuracy. , the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

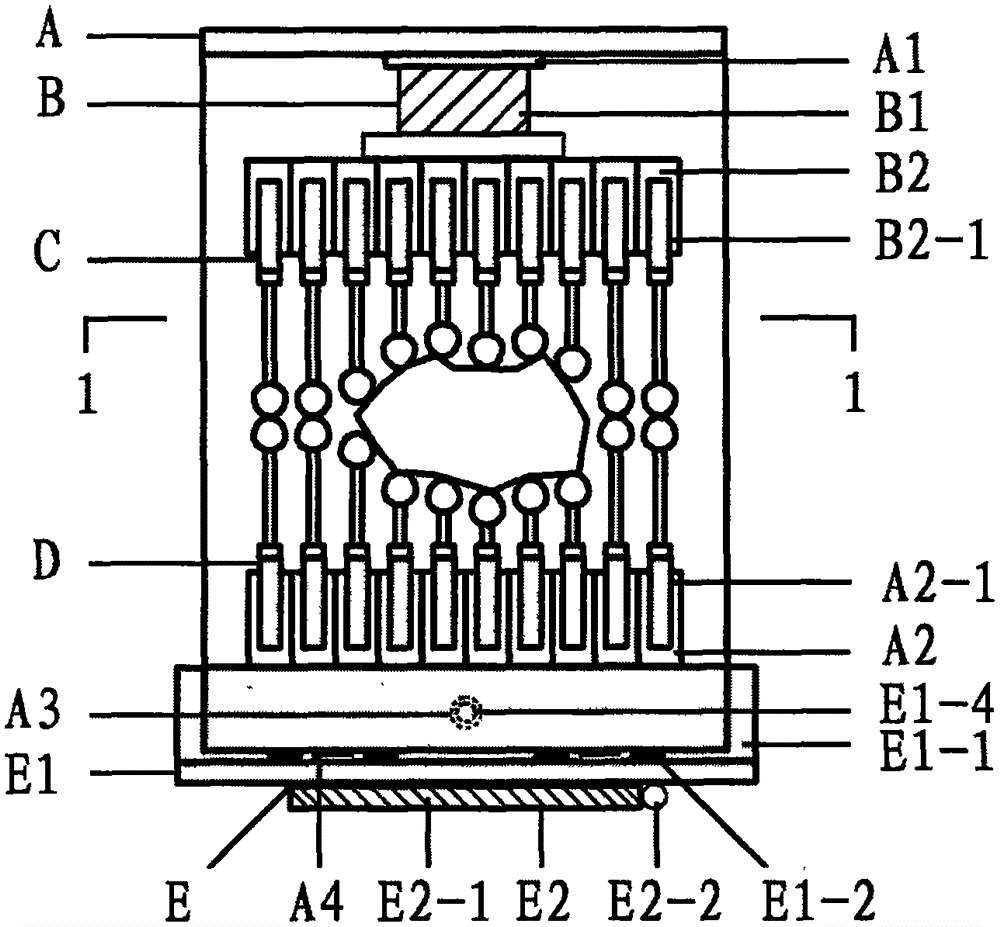

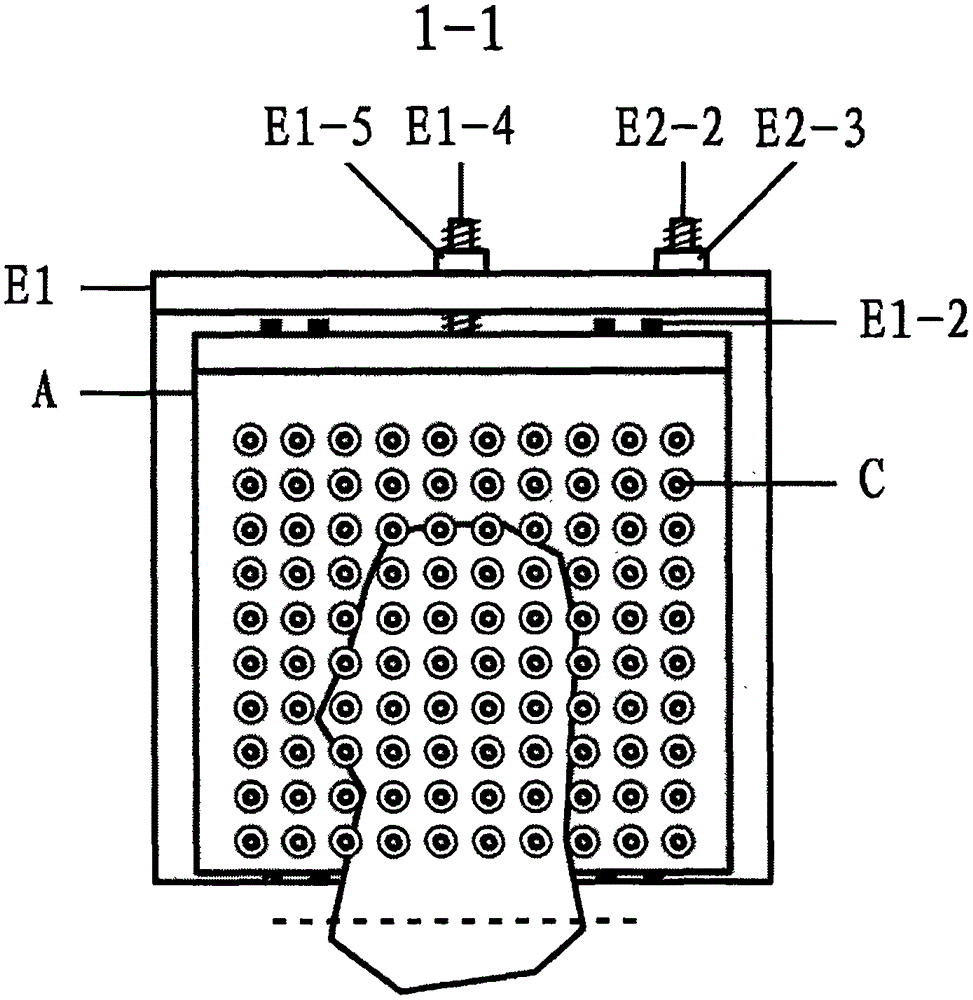

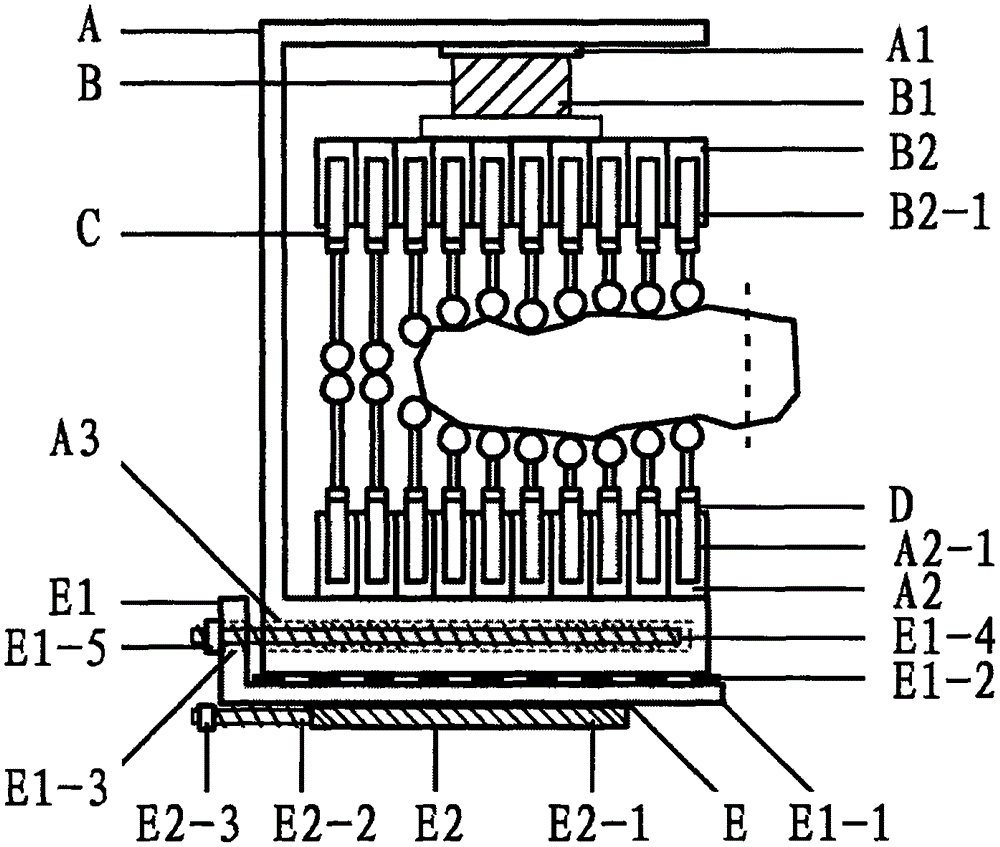

[0019] An adaptive clamping device for a rock cutter, which consists of an outer support A, an integral loading module B, an upper clamping rod C, a lower clamping rod D and a fine-tuning base E. Before loading the raw rock sample, turn on the power and pressure drive source of the clamping device; place the raw rock sample to be cut on the dot matrix formed by the lower clamping rod D, and manually adjust its posture according to the cutting position; after the sample is placed , control the lower clamping rod D to extend the lower clamping rod body D3, so that the elastic shock-absorbing contact pad D4 fits the bottom surface of the sample adaptively; control the pressure unit B1 of the overall loading module B, and drive the upper clamping support B2 to descend , when the upper clamping rod C comes into contact with the sample, the upper clamping rod support B2 stops falling; the upper clamping rod C is controlled to make the upper clamping rod body C3 stretch out, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com