Sealing method for container

A container and bottle body technology, applied in the field of container packaging, can solve problems such as not easy to open, allergic sores, damage, etc., to achieve the effect of strengthening the seal and extending the warranty period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

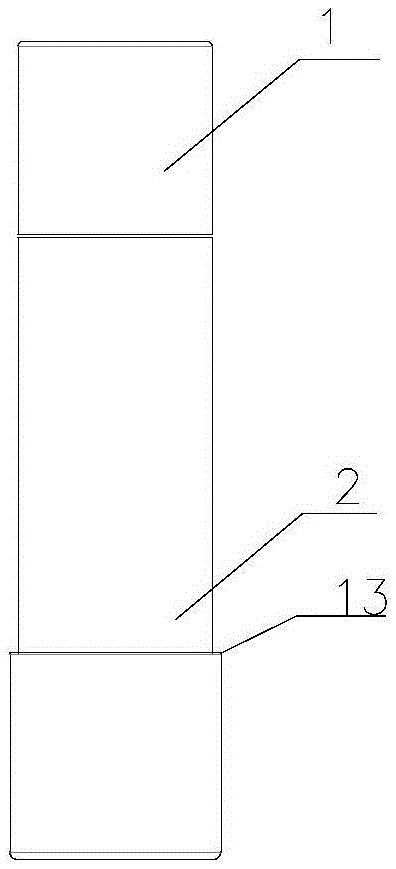

[0031] 1. Making the bottle body

[0032] The bottle body 2 is a convex cylindrical structure with a large bottom and a small top, made of glass or plastic.

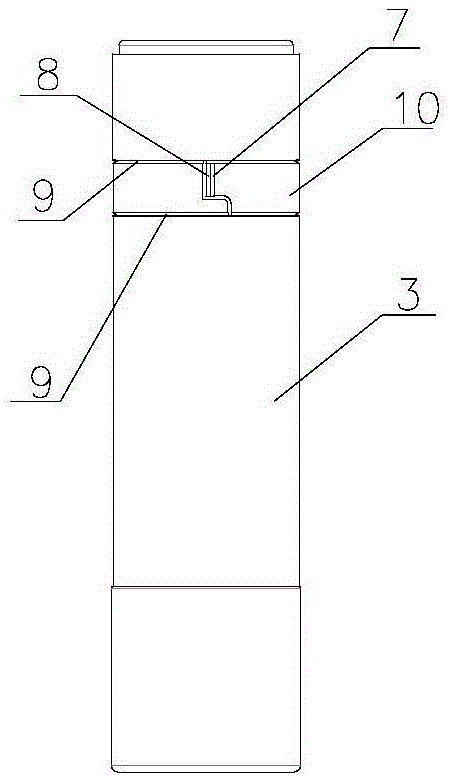

[0033] 2. Bottle cap

[0034] The bottle cap 1 is composed of an upper cover 4 , a lower cover 5 and a shoulder fitting 6 , and a product identification 12 is provided on the surface of the shoulder fitting 6 .

[0035] The bottle body and the bottle cap are threaded, and after the bottle cap is closed, the shoulder fitting is located at the position where the bottle cap is connected to the bottle body.

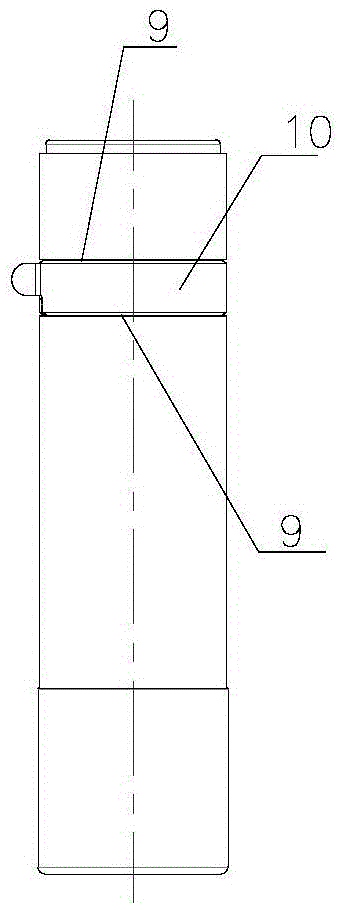

[0036] 3. The production of the annular sealing sleeve

[0037] Using thermal expansion and contraction or elastic materials (rubber: styrene-butadiene, butadiene, natural rubber, butyl rubber, nitrile rubber, ethylene-propylene rubber, isoprene rubber, silicone rubber, fluororubber / silicone: silicone rubber, oxidized silica gel, Silicic acid gel, methyl silicone rubber (MQ), vinyl silicone rubber (VMQ), phenyl silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com