Organic fertilizer fermentation apparatus

A fermentation device and a technology for organic fertilizers, applied in the field of organic fertilizer fermentation devices, can solve the problems of no sterilization, low oxygen content in the bottom layer, prolonged fermentation cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

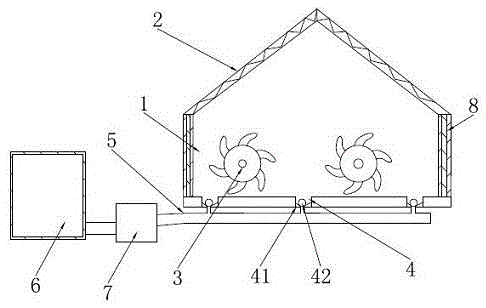

[0013] Such as figure 1 As shown, reference numerals include fermentation tank 1, solar shed 2, mixer 3, one-way air duct 4, air pipe 5, sterilization chamber 6, heat pump 7, insulation layer 8, funnel 41, and ball 42.

[0014] The top of the fermentation tank 1 is fixed with a solar shed 2, the inner wall of the fermentation tank 1 is provided with an insulation layer 8, the inside of the fermentation tank 1 is equipped with a mixer 3, and the bottom of the fermentation tank 1 is provided with a one-way air channel 4, and the one-way air channel 4 passes through the air pipe 5 It is fixedly connected with the inlet end of the heat pump, and the outlet end of the heat pump 7 is fixedly connected with the sterilization chamber 6 . One-way airway 4 is that funnel structure comprises, funnel 41, spherical ball 42, funnel 41 bottom openings, opening is connected with trachea 5, and in the funnel 41, ball 42 is movably connected, and ball 42 diameter is greater than funnel 41 botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com