Intelligent energy absorbing material and preparation method thereof

An energy-absorbing material and intelligent technology, applied in the field of intelligent energy-absorbing materials and their preparation, can solve problems such as limited operating temperature range, equipment damage, impact energy dissipation, etc., and achieve the effect of meeting the protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

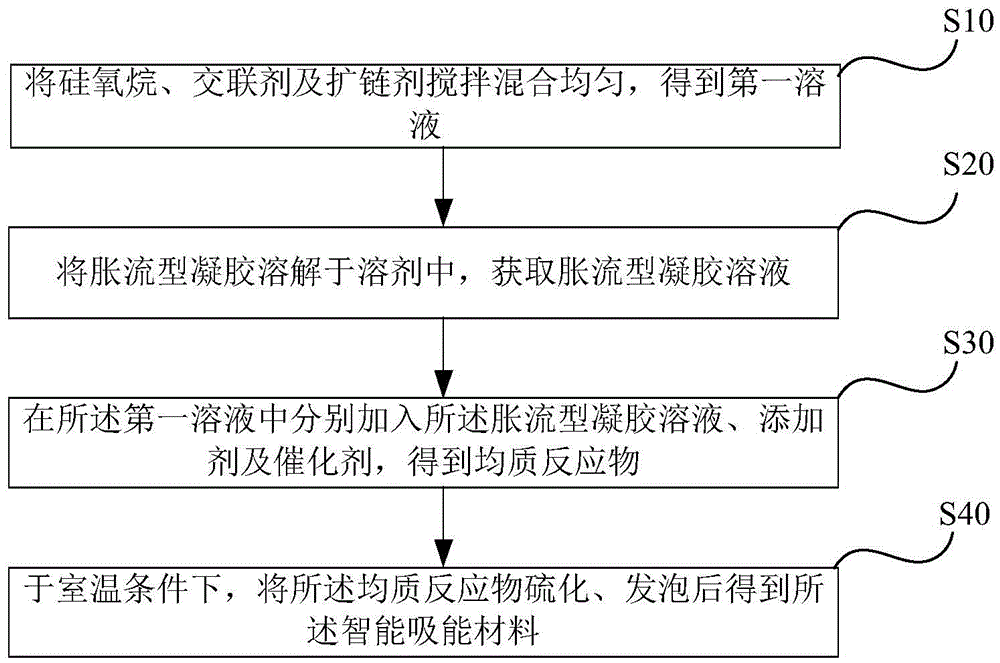

[0030] Such as figure 1 As shown, the preparation method of an intelligent energy-absorbing material in one embodiment includes the following steps:

[0031] Step S10: Stir and mix the siloxane, crosslinking agent and chain extender evenly to obtain a first solution;

[0032] Preferably, the siloxane is at least one of dimethyl siloxane, methyl vinyl siloxane, and methyl phenyl siloxane.

[0033] Preferably, the crosslinking agent is at least one of ethyl orthosilicate, propyl orthosilicate, and polymethyltriethoxysilane; the chain extender is bismethoxysiloxane, bisethyl At least one of oxysiloxane, difunctional acetamidosilane, and hydroxyl silicone oil.

[0034] Preferably, the mass ratio of the crosslinking agent to siloxane ranges from 0.5% to 20%, and the mass ratio of the chain extender to siloxane ranges from 0.5% to 20%.

[0035] Step S20: dissolving the dilatant gel in a solvent to obtain a dilatant gel solution;

[0036] Preferably, the solvent is silicone oil. ...

Embodiment 1

[0059] The preparation process of the smart energy-absorbing material of this embodiment is as follows:

[0060] Dimethyl siloxane is used as the base material, ethyl orthosilicate is used as the crosslinking agent, bismethoxysiloxane is used as the chain extender, and the first solution is obtained by stirring evenly; on the other hand, the dilatant gel is dissolved In silicone oil, a dilatant gel solution was obtained. Then pour the dilatant gel solution into the first solution, add montmorillonite as an additive, and obtain a uniformly mixed solution under the action of mechanical stirring, pour the obtained liquid into a mold, and foam at room temperature. After the product is completely foamed, it is post-treated: it is heated and deeply cured in an oven, the curing temperature is 250°C, and the curing time is 1.5 hours to obtain an intelligent energy-absorbing material.

Embodiment 2

[0062] The preparation process of the smart energy-absorbing material of this embodiment is as follows:

[0063] Using methyl vinyl siloxane as the matrix material, propyl orthosilicate as the crosslinking agent, and bisethoxysiloxane as the chain extender, stir evenly to obtain the first solution; on the other hand, dilatant gel Dissolved in silicone oil to obtain a dilatant gel solution. Then pour the dilatant gel solution into the first solution, add montmorillonite as an additive, and obtain a uniformly mixed solution under the action of mechanical stirring, pour the obtained liquid into a mold, and foam at room temperature. After the product is completely foamed, it is post-treated: it is heated and deeply cured in an oven, the curing temperature is 250°C, and the curing time is 1.5 hours to obtain an intelligent energy-absorbing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com