Smelting device

A smelting equipment and smelting furnace technology, applied in the field of metallurgical manufacturing, can solve the problems of long smelting cooling time and low smelting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

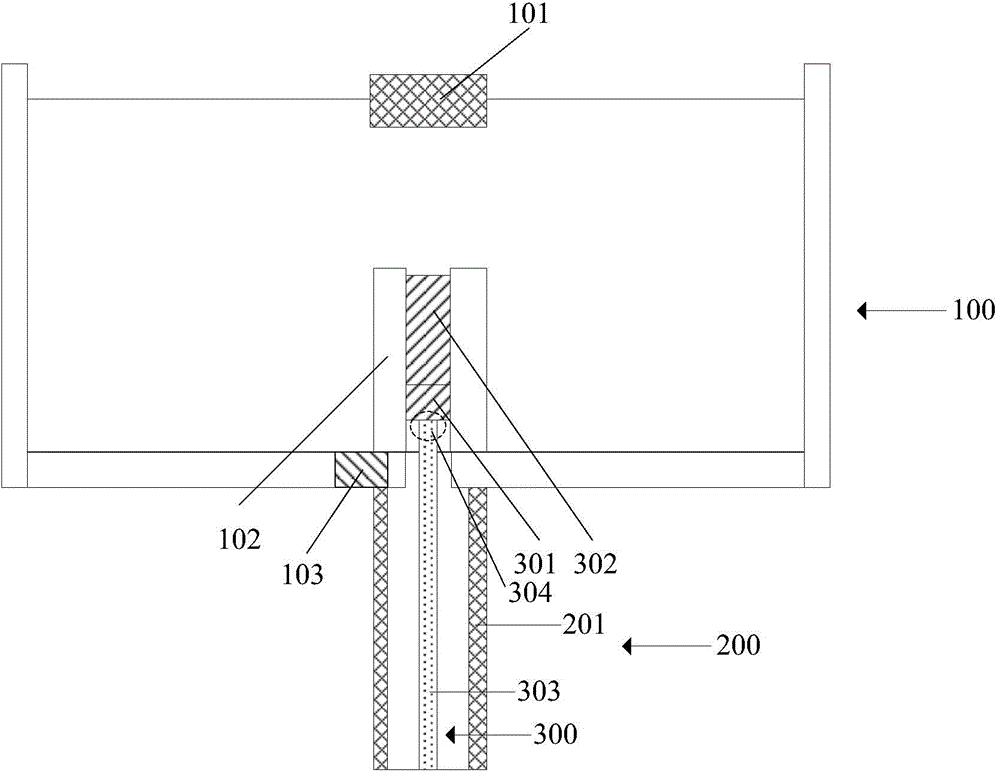

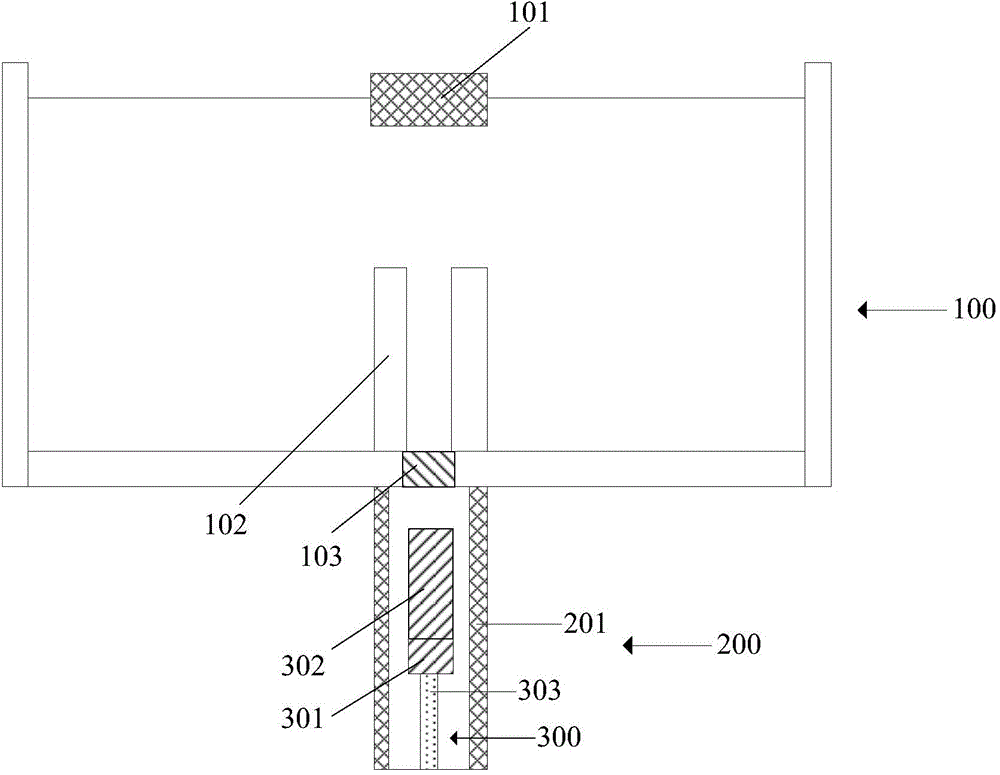

[0028] As mentioned in the background art, in the existing EB smelting, after the ingot is formed, the cooling process of the furnace body is too long, and the smelting efficiency is low.

[0029] The smelting furnace body of the present invention is connected with the cooling chamber, and the smelting furnace body is provided with a crucible and an ingot pulling device. When smelting is carried out in the smelting furnace body, the crucible is used to hold the molten metal and shape the molten metal to form a casting. Ingot, the first end of the ingot pulling device is used to support the molten metal or ingot. After the molten metal is completely solidified to form an ingot, the end for supporting the molten metal or ingot can shrink from the melting furnace body to the inside of the cooling chamber, so that the ingot supported on the ingot pulling device The ingot enters the inside of the cooling chamber, and the ingot is cooled separately in the cooling chamber, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com