A crochet fancy twisting machine

A twisting machine and crocheting technology, applied in the field of crochet fancy twisting machines, can solve the problems of inability to guarantee the gap between the upper and lower cams, product quality and output limitations, affecting productivity, etc. Needle problems, stable and reliable clutch performance, cost and energy savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

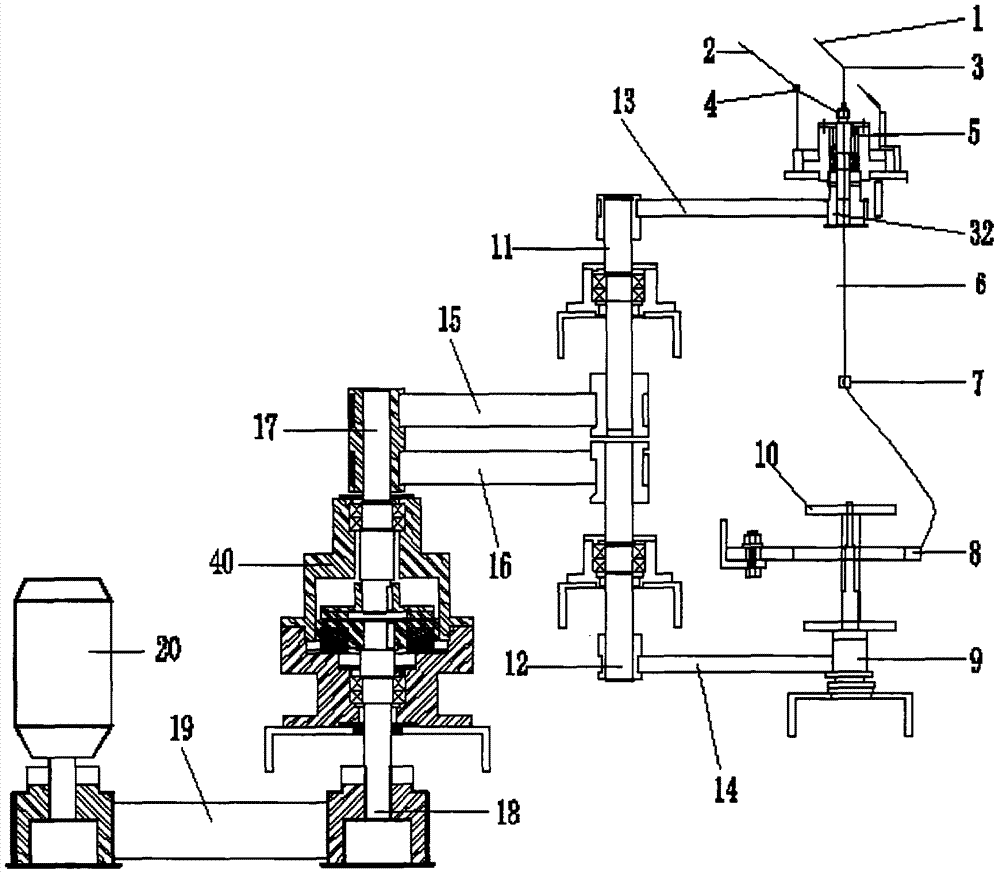

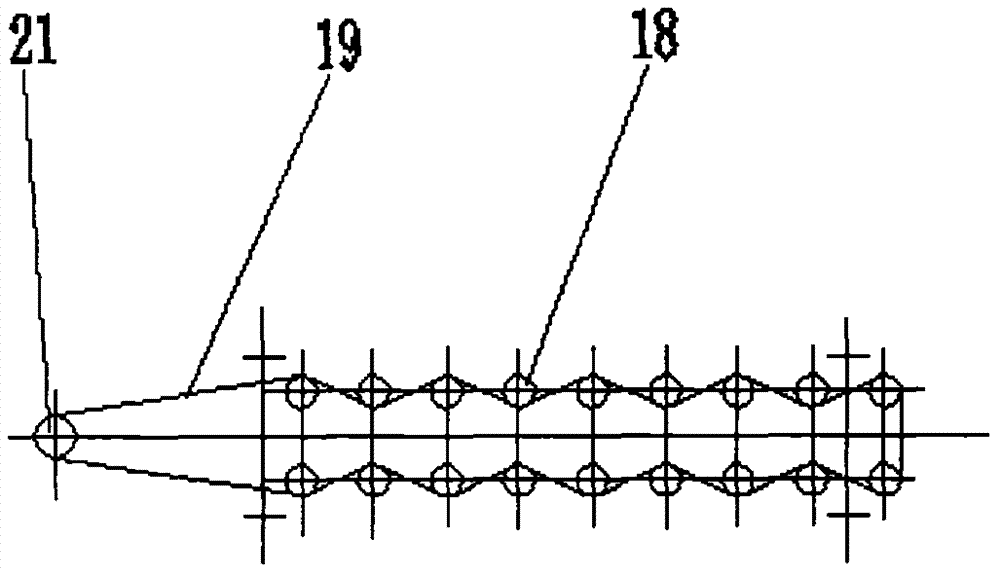

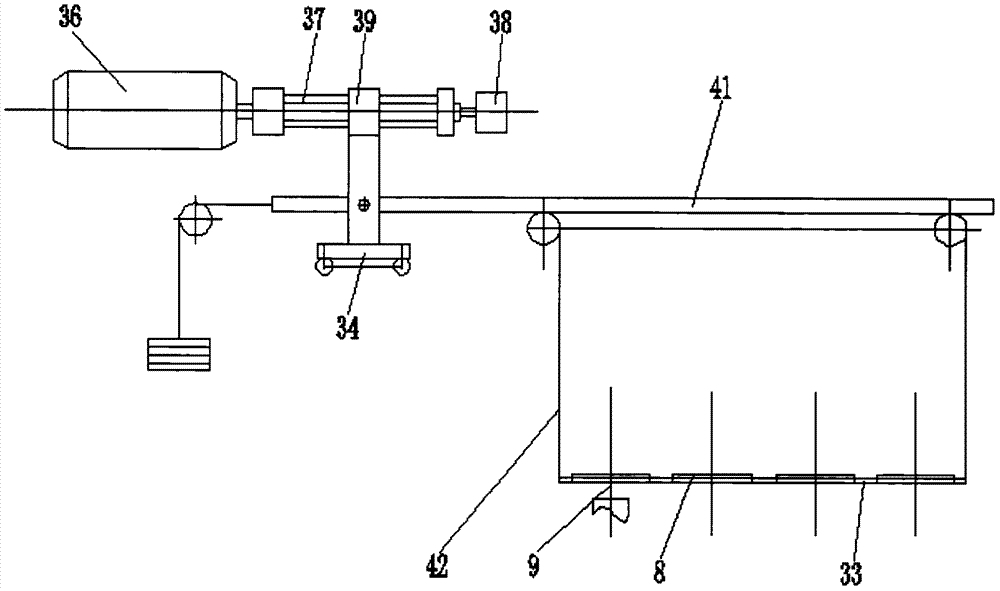

[0026] Embodiments of the present invention provide a crochet fancy twister, such as Figure 1 to Figure 4 As shown, it includes a transmission device, a controller, a yarn breaking self-stop device, a plurality of crochet heads and a plurality of winding guide devices, the crochet heads are connected with the transmission device through the first transmission belt 13, and the winding guide devices pass through The second transmission belt 14 is connected with the transmission device, and the controller is electrically connected with the transmission device, the winding yarn guide device and the yarn breaking self-stopping device. Send the yarn breakage signal to the controller, and the controller controls the operation and stop of the transmission device according to the received yarn breakage signal;

[0027] The crochet head includes a housing 31 with an inner cavity, a needle cylinder 22 arranged in the housing 31 and a crochet transmission wheel 32 connected to the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com