Double-sided composite beam and its construction method

A construction method and technology of laminated beams, applied in the direction of joists, girders, truss beams, etc., can solve the problems of production environment, transportation and installation conditions constraints, restricting the development of housing industrialization, and difficult to guarantee the quality of connections, etc., to save consumables , shorten the construction period, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

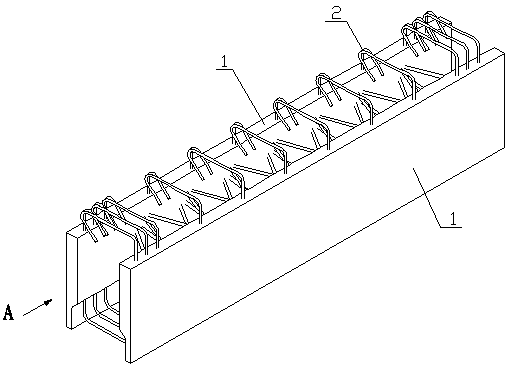

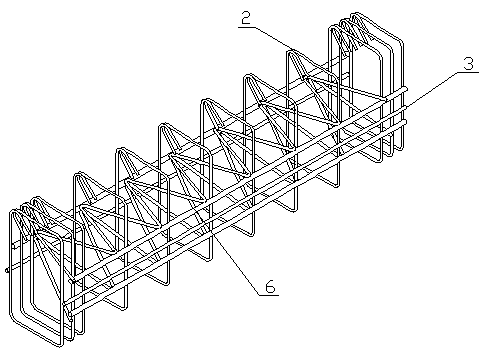

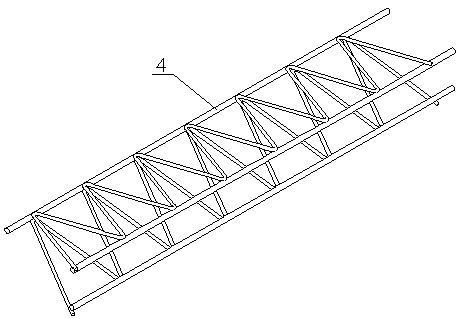

[0033] A double-sided composite beam, which consists of: a steel frame 6, a precast concrete slab 1, the vertical sides of the steel frame are poured with the precast concrete slab, the steel frame includes truss bars 4, the A group of beam stirrups 2 are installed in the truss bars, the vertical edges on both sides of a group of beam stirrups are fixed with the truss bars, and the vertical edges on both sides of a group of beam stirrups are fixed with a group of structural steel bars. 3 is fixed, a set of beam stirrups are respectively pierced with beam main bars 5 at the four corner arc positions, and the inner side of the precast concrete slab has a smoothly reduced cross-section.

Embodiment 2

[0035] In the double-sided laminated beam described in Embodiment 1, a group of beam stirrups are arranged in parallel, and the beam stirrups are closed loops connected by butt welding or bent at the ends into 135-degree hooks The above-mentioned hook forms a closed loop or a long and one short U-shape, and the double-sided composite beam is used for setting the insulation layer on the surface of the prefabricated concrete slab on the outdoor side or setting the insulation layer and decoration at the same time. layer.

Embodiment 3

[0037] A construction method of a double-sided composite beam, the method is first of all according to the actual use position of the double-sided composite beam, reserve installation space for the floor slab on the upper or lower part of the precast concrete slabs on both sides, and install the double-sided composite beam The surface of the prefabricated concrete slab used on the outdoor side is provided with an insulation layer or an insulation layer and a decorative layer at the same time. After the double-sided laminated beam is manufactured according to the requirements, it is transported to the construction site, and the installation conditions are met, and the support is set and fixed. Bottom formwork, hoisting double-sided laminated beams, adjusting its position and elevation, tying the beam main reinforcement, after the beam main reinforcement is bound, bending the beam stirrup into a closed ring shape, and the beam main reinforcement passes through the Welding connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com