Safe explosion-proof unloading system of oil and gas well

A technology of explosion-proof discs and oil pipes, which is applied in safety devices, dust prevention, fire prevention, etc., and can solve problems such as imperfect technology and insufficient supporting measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

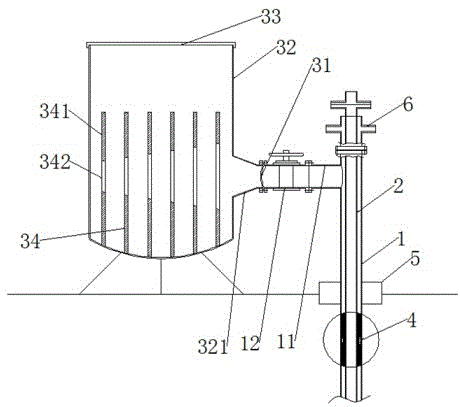

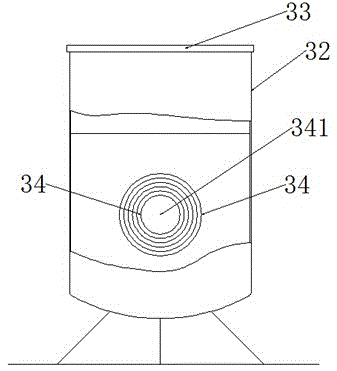

[0027] Embodiment 1 Explosion-proof unloading device 3 on the well

[0028] See figure 1 , 2 , explosion-proof discharge device 3 on the well, which includes: explosion-proof plate 31, explosion-proof pressure relief device 32, casing tee 11 and / or tubing tee, and the explosion-proof pressure relief device 32 is cylindrical and the bottom is hemispherical , the top is provided with a cylinder cover 33, the cylinder cover 33 is a soft waterproof material, such as rainproof cloth, plastic film; the underside of the explosion-proof pressure relief device 32 is provided with a burst-proof disk interface 321, which is connected with the sleeve tee 11 through a flange, The explosion-proof plate 31 is installed between the two flanges, the casing tee 11 and / or the tubing tee are arranged below the Christmas tree, and the casing suspension 5 is above; the explosion-proof plate 31 and the tee 11 are also provided with valve 12;

[0029] Also be provided with energy-absorbing devic...

Embodiment 2

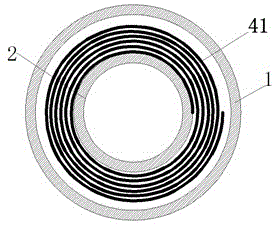

[0030] Embodiment 2 Downhole explosion-proof unloading device 4

[0031] See Figure 1-6 , the downhole explosion-proof unloading device 4, which is installed on the outer periphery of the tubing 2 from the bottom of the casing suspension 5 to the top of the oil production pump 7, and an explosion-proof barrier 41 is installed in sections, and each section of the explosion-proof barrier 41 is fixed on the tubing through a clamp 42. Oil pump end 7 to casing suspension end 5, non-metallic fire retardant material with a length of 5-15 meters, explosion-proof barrier 41 of metal mesh fire retardant material with a length of 15-25 meters, metal mesh fire retardant material explosion-proof barrier group 43 , non-metallic mesh fire-blocking material explosion-proof barrier group 44, ..., non-metallic mesh fire-blocking material explosion-proof barrier group 44, casing suspension 5 end is the explosion-proof barrier 41 of metal mesh fire-blocking material with a length of 5-15 meter...

Embodiment 3

[0034] Example 3 Oil and gas well safety explosion-proof unloading system

[0035] See Figure 1-6 , oil and gas well safety explosion-proof unloading system, which includes: downhole explosion-proof unloading device 4, uphole explosion-proof unloading device 3, uphole explosion-proof unloading device 4; The lower part, the upper part of the casing suspension 5, is connected with the explosion-proof discharge device 3 on the well; it is used for the explosion-proof pressure relief of the casing 1;

[0036] The explosion-proof unloading device 3 on the well is the explosion-proof unloading device 3 on the well described in Embodiment 1;

[0037] Described downhole explosion-proof unloading device 4 is downhole explosion-proof unloading device 4 described in embodiment 2;

[0038] The oil and gas well safety explosion-proof unloading system also includes an explosion-proof unloading device 3 on the well for explosion-proof and pressure relief of the tubing 2, and the tubing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com