Control system and method for heat medium water pipe type heat exchanger

A tubular heat exchanger and control system technology, applied in the field of control systems, can solve the problems of condensation, corrosion, fouling and scaling on the tube walls of flue gas coolers and flue gas heaters, so as to avoid condensation and Corrosion, avoiding smoke and dust adhesion, and ensuring the effect of pipe wall temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

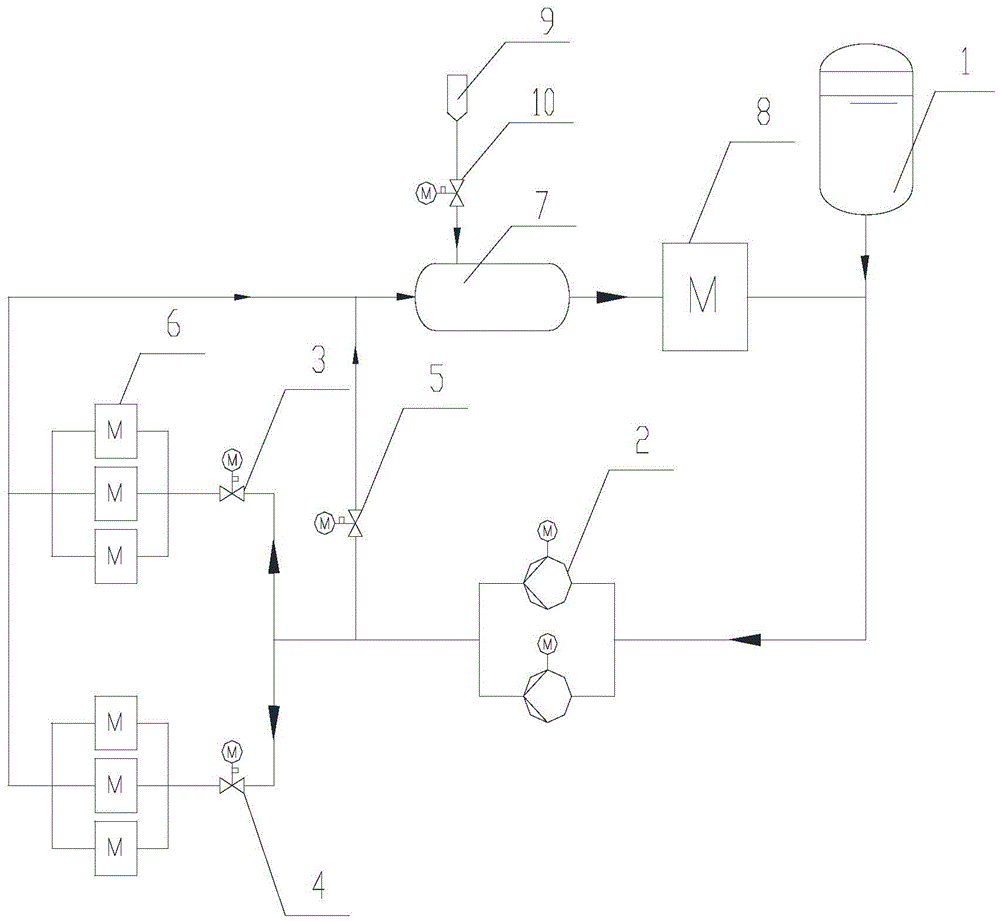

[0022] In addition to the flue gas cooler 6 and the flue gas heater 8, the heat medium water tube heat exchanger of this embodiment is composed of the following auxiliary systems: heat medium water replenishment system, the main equipment includes heat medium water replenishment tank 1, heat medium water circulation System, the main equipment includes heat medium water pump 2, heat medium steam heating system, the main equipment includes heat medium steam heater 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com