A precision debugging method of CNC bending machine

A debugging method and technology of a bending machine, applied in the direction of digital control, electrical program control, etc., can solve the problems of excessive slider and instability, and achieve the effects of improved bending accuracy, fast debugging speed and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0042] This scheme adopts one DELEM numerical control bending machine, and the numerical control system model can be above DA52s, and this embodiment adopts DA52s; one USB interface keyboard.

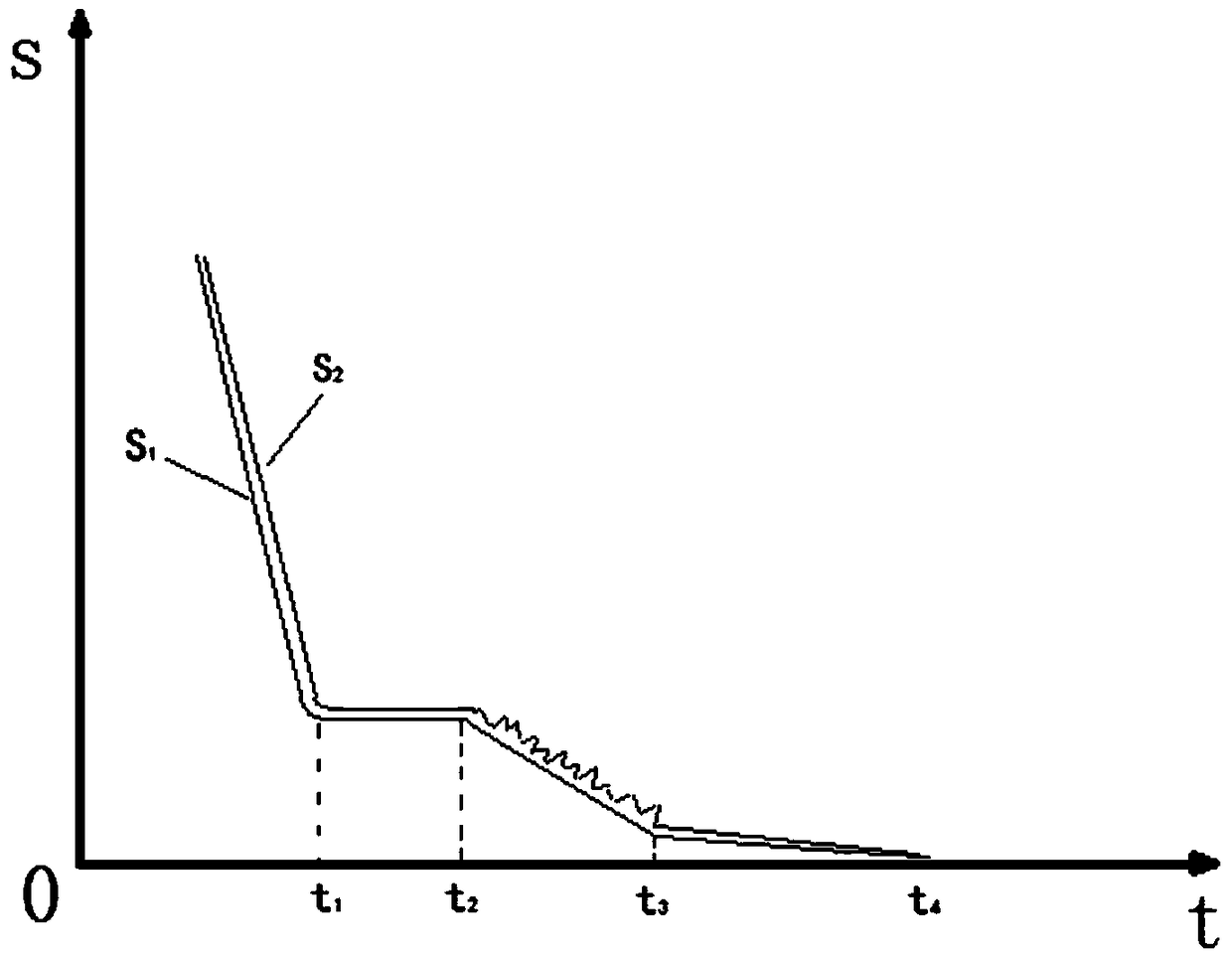

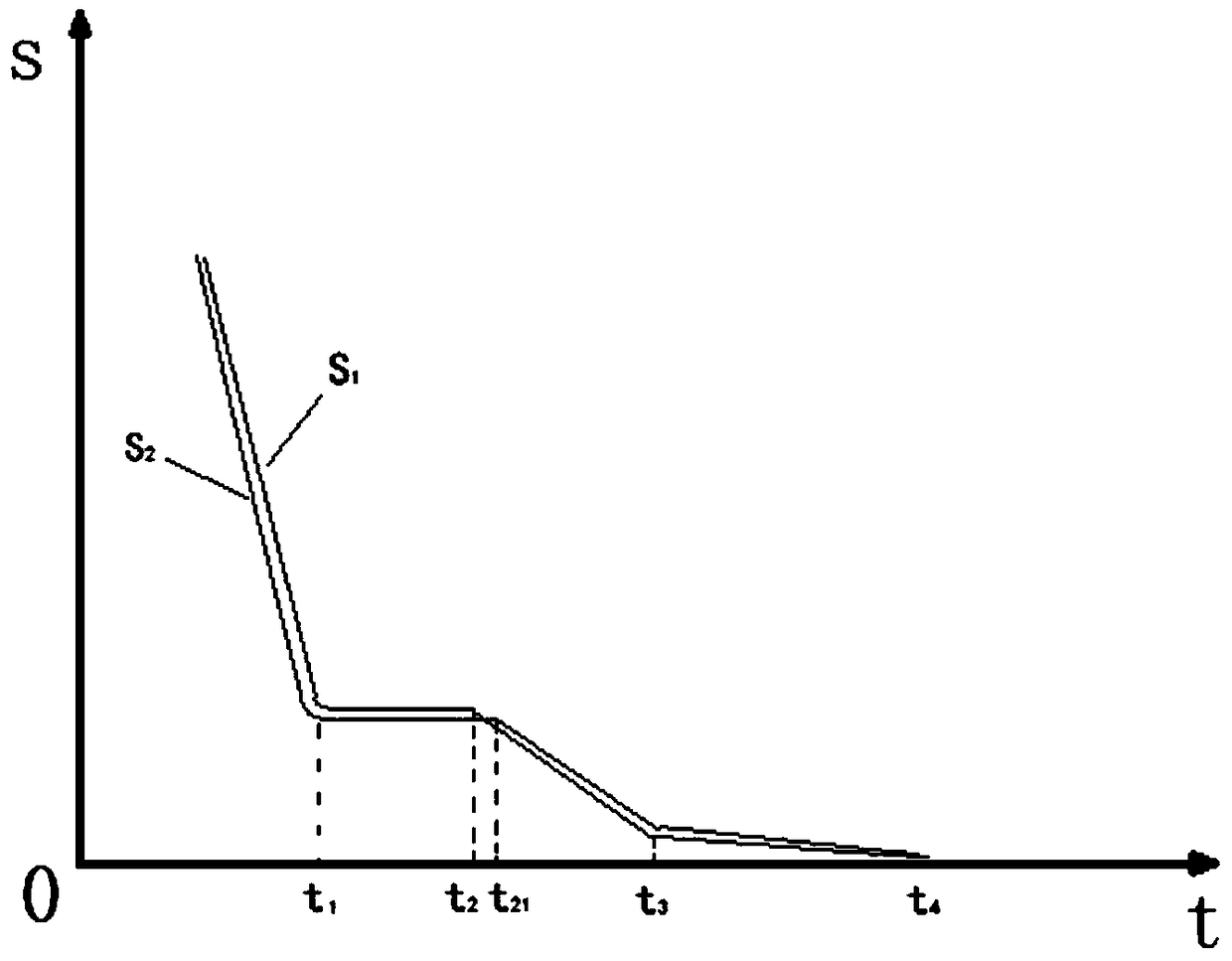

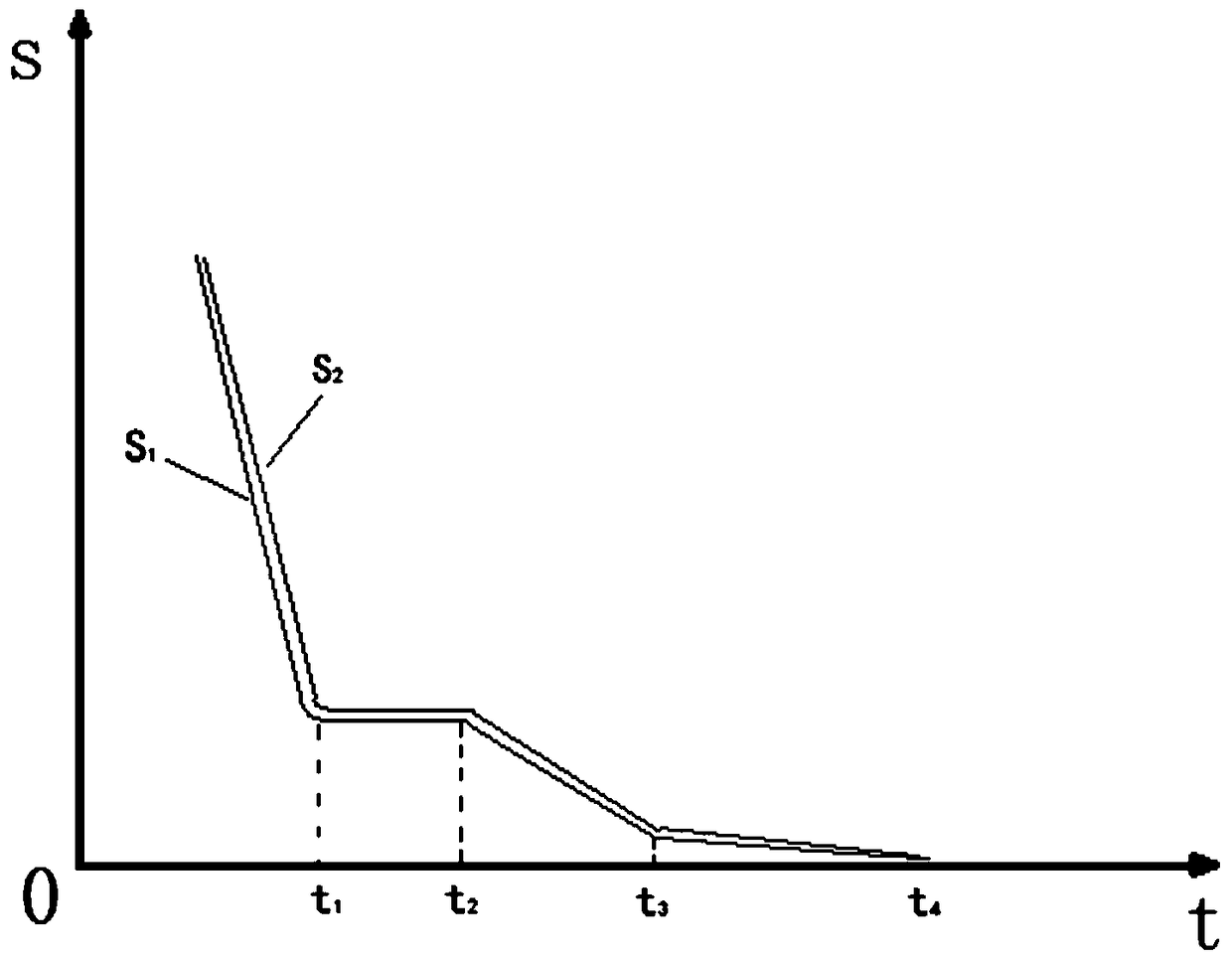

[0043] The bending accuracy of the bending machine is mainly affected by the working movement, which will be described in detail below.

[0044] The control algorithm of the slider is based on the trajectory control of the slider movement. The system requires that the speed, acceleration and deceleration of each bending stage must be programmed. The parameters required for each different pressure bending requirements and different bending machines are different. In the prior art, the same modular parameters are used for a bending machine, and there is no need for process errors due to process errors. And the optimal parameter setting required for bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com