Mineral insulated cable pair twist production technology in same metal sleeve

A technology for mineral insulated cables and production processes, which is applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as parallel placement, and achieve the effects of small outer diameter, compact structure, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

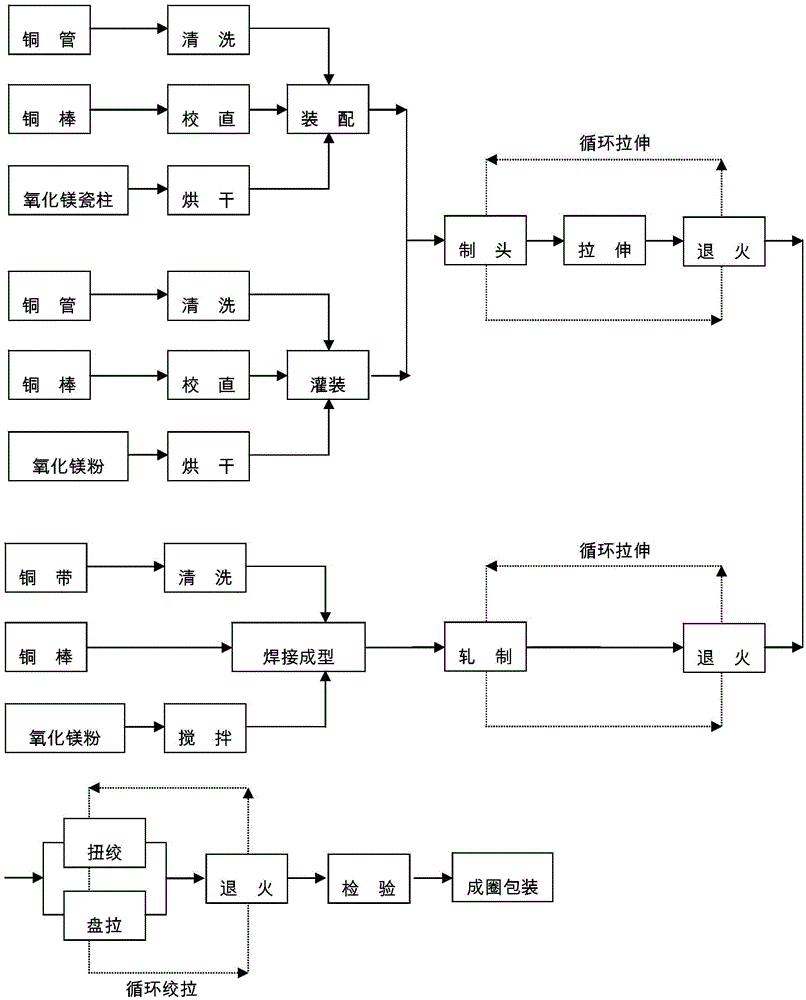

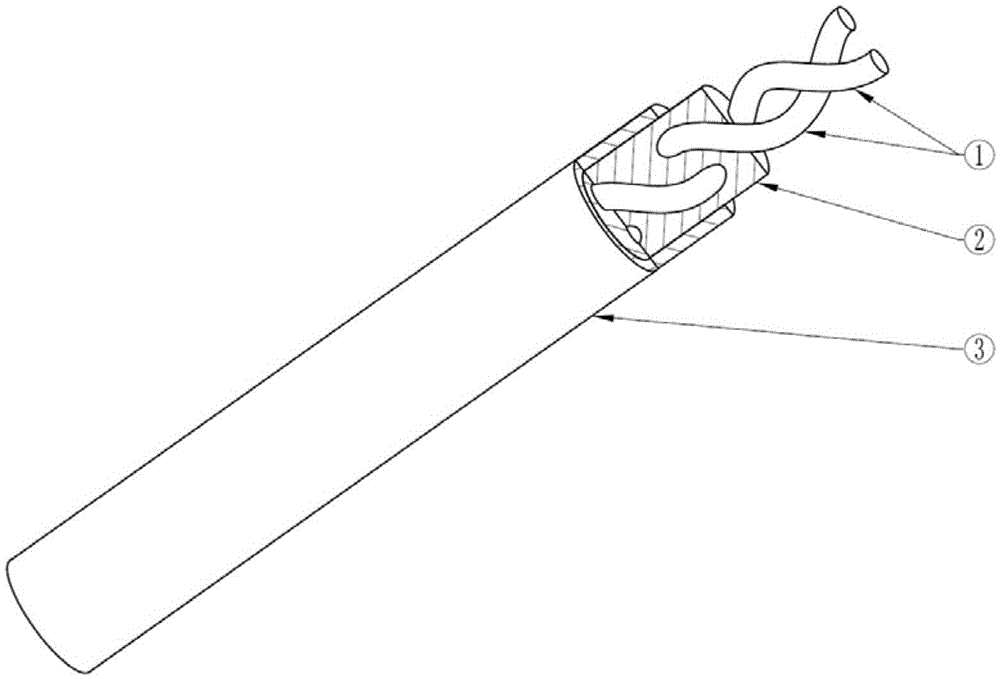

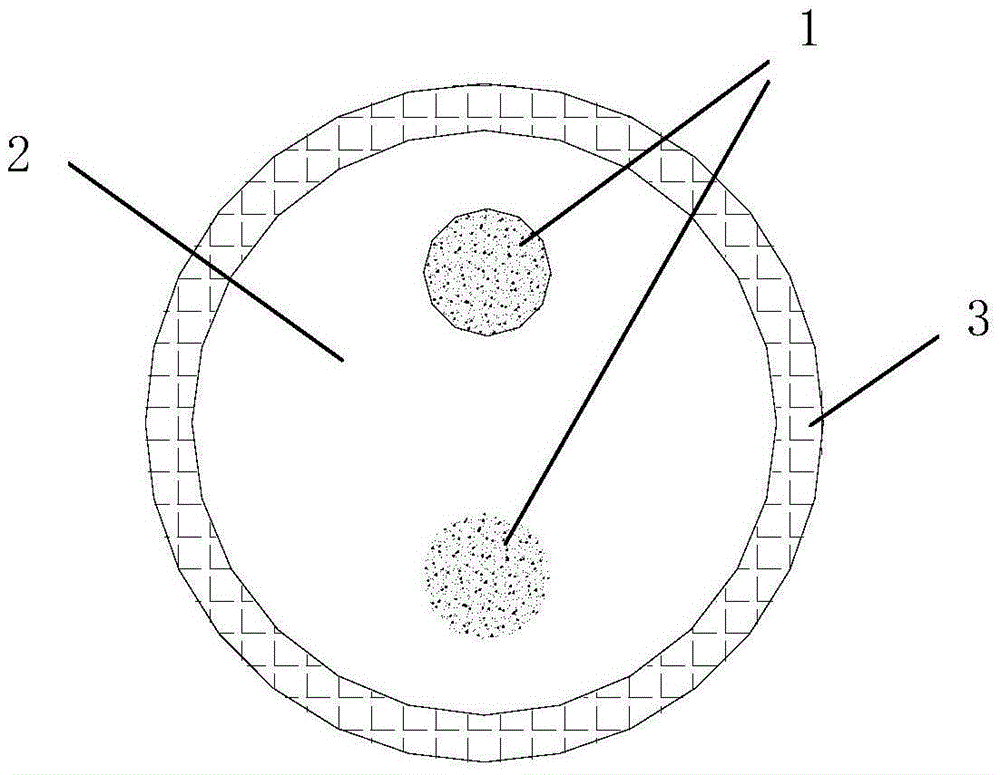

[0020] see figure 1 , the production process of mineral insulated cable pairs twisted in the same metal sheath, the cable is a 2-core mineral insulated cable, including 2 parallel copper conductors, an inorganic magnesium oxide insulation layer, and a copper sheath, including the following steps:

[0021] 1) Pull the 2-core mineral insulated cable close to the outer diameter of the finished product, and anneal it to a soft state, during which the two conductors in the mineral insulated cable are parallel;

[0022] 2) Through the joint production of the torsion device and the coiling machine in series, the torsion device gradually twists and deforms the cable along the center line, so that the two parallel conductors inside the cable are gradually twisted, and then the metal sheath of the cable is eliminated by reducing the diameter of the coiling machine twist marks;

[0023] Usually, the twisting starts at the penultimate or third drawing, and the following is the production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com