Method of manufacturing halogen lamp and halogen lamp

一种卤素灯、灯泡的技术,应用在卤素灯领域,能够解决涂层或膜层易被划伤、损坏等问题,达到好粘性、改进涂层粘性、避免损耗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

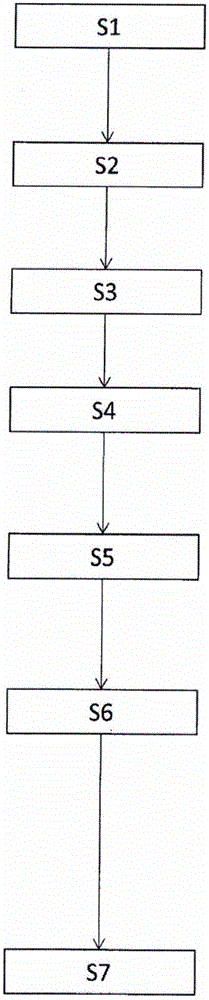

[0062] figure 1 The method of manufacturing a halogen lamp known to the inventor is shown in conjunction with Figs. 2a-2d. The method includes steps S1-S7. The respective steps are explained with reference to FIGS. 2a-2g, and FIGS. 2a-2g show the corresponding state of each method step during manufacturing.

[0063] The first step S1 refers to providing the glass tube mat shown in Figure 2a. The glass tube mat 101 of FIG. 2a is made of, for example, quartz glass or hard glass, and is configured as an annular hollow body shown in a side view in FIG. 2a. The length of the glass tube mat 101 has been cut to the required length for manufacturing the bulb 103. Such a suitable length is, for example, 8 cm. The glass tube mat 101 is thus cut to the correct length to manufacture the bulb 103, which is referred to as "cutting the workpiece".

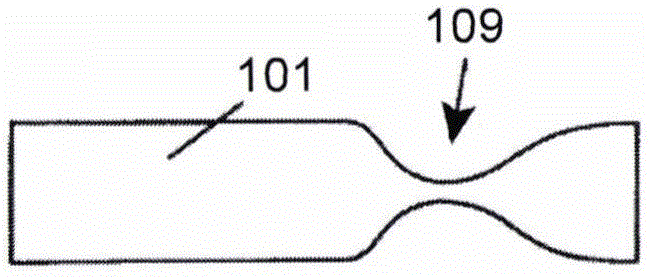

[0064] The subsequent step S2 includes introducing a pipette-like taper 109 into the glass tube mat 101. The tapered portion 109 is obtained by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com