Series welding machine scaling powder auxiliary receiving disc and series welding machine

A stringer and flux technology, which is applied in the field of stringer flux auxiliary connection plate and stringer, can solve the problems of pollution in the non-spraying area of the battery sheet, different spraying starting points before and after, and can not meet the spraying accuracy, etc., to achieve replacement The effect of cycle extension, improved consistency, and improved tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with each accompanying drawing, the present invention is described in detail.

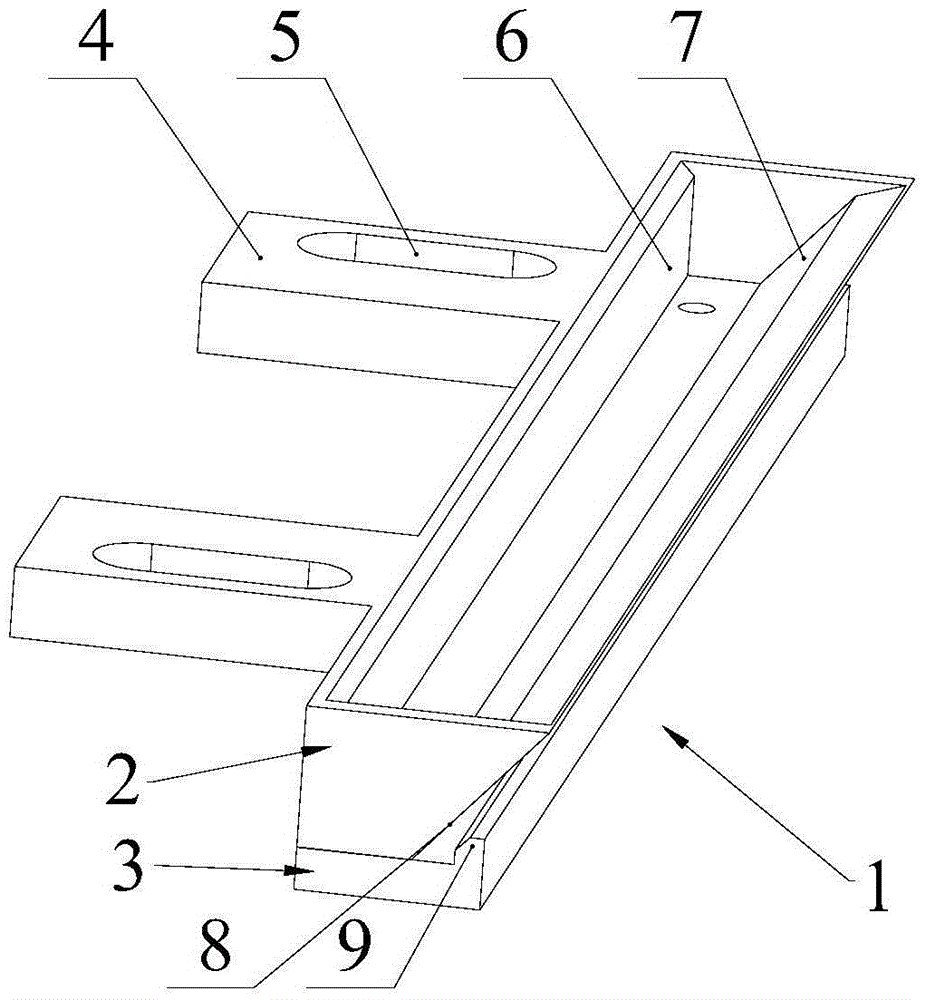

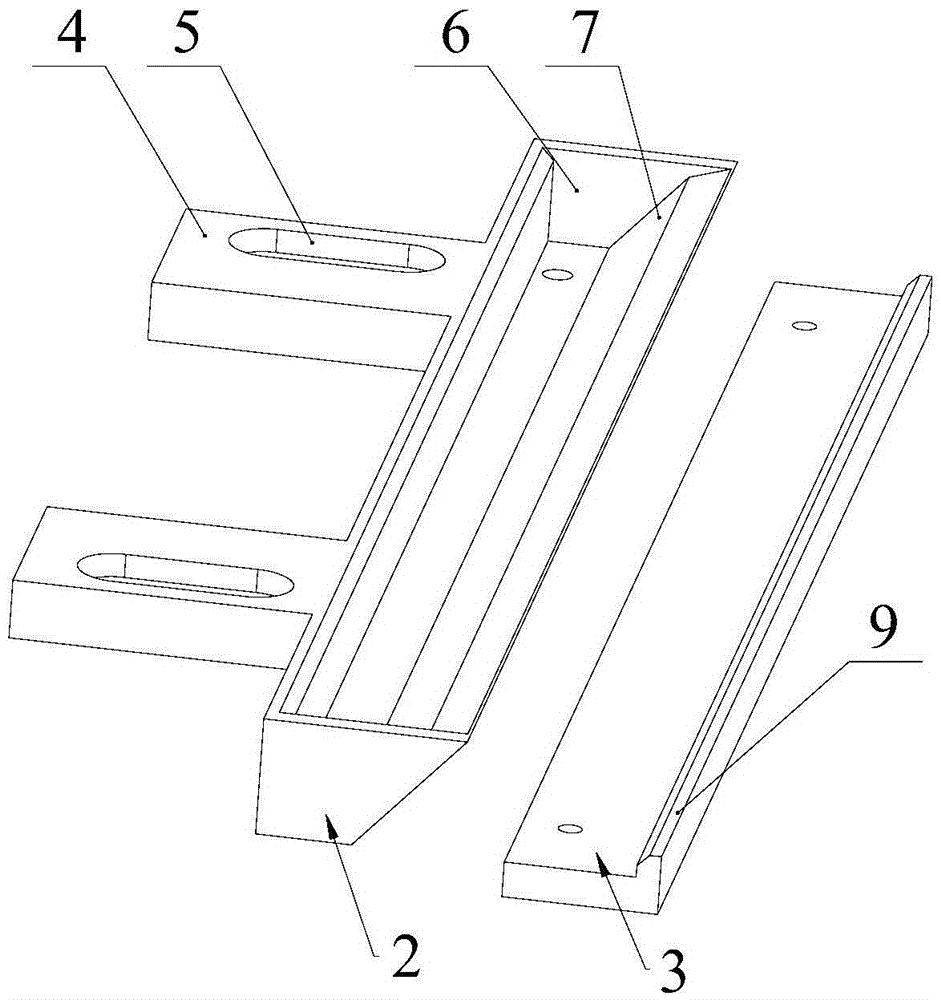

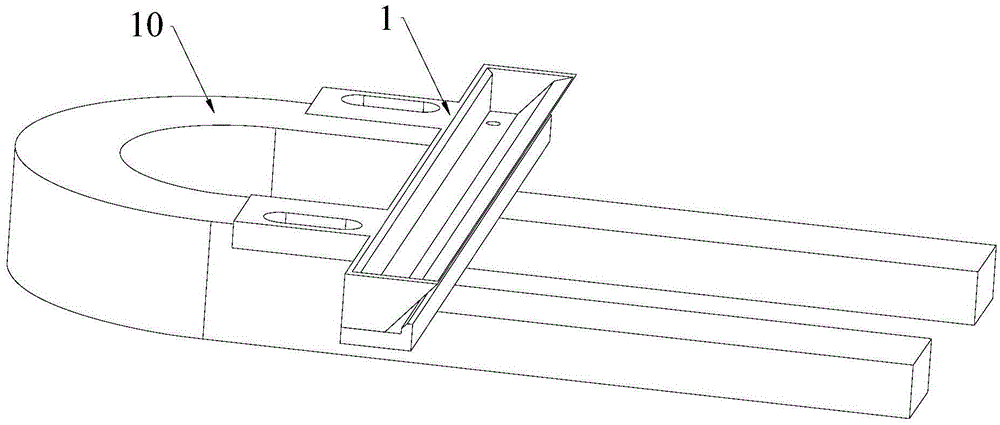

[0036] Such as figure 1 with 2 As shown, a flux auxiliary land 1 of a stringer includes a land body 2 having a receiving groove 6 and a mounting portion 4 through which the land body 2 is relatively fixed to the manipulator of the stringer.

[0037] In this embodiment, the mounting part 4 has a mounting hole 5 , and the land body is fixed on the manipulator of the stringer by a fastener matched with the mounting hole. The installation hole 5 is a strip hole, and the strip hole can adjust the installation position of the connecting plate body relative to the manipulator, which facilitates the cooperation between the connecting plate and the manipulator, and reduces the difficulty of debugging.

[0038] In this embodiment, an absorbing material (not shown in the figure) is installed in the absorbing groove, and the flux can be effectively absorbed by setting the absorbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com