Combined machining line body for insulation boards

A composite processing and thermal insulation board technology, applied in thermal insulation, lamination devices, lamination auxiliary operations, etc., can solve the problems that are difficult to be accepted by ordinary consumers, affect the aesthetics of exterior walls, hidden dangers of calcium silicate board safety, etc., and achieve savings Manpower, easy to operate, the effect of reducing the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

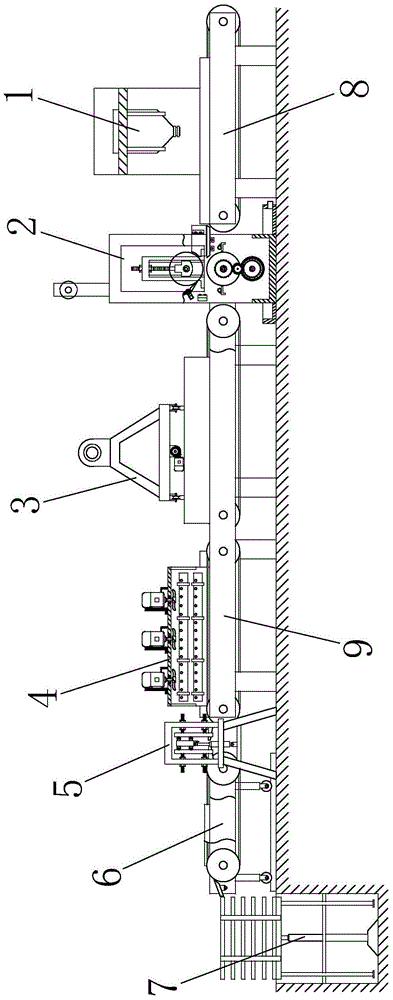

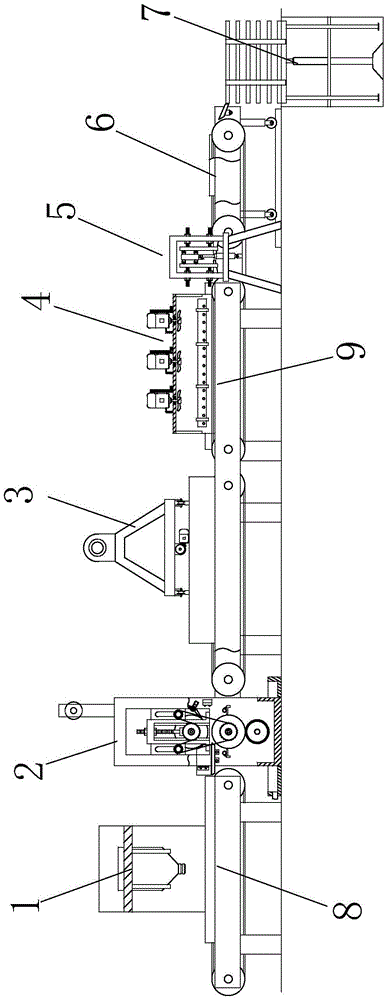

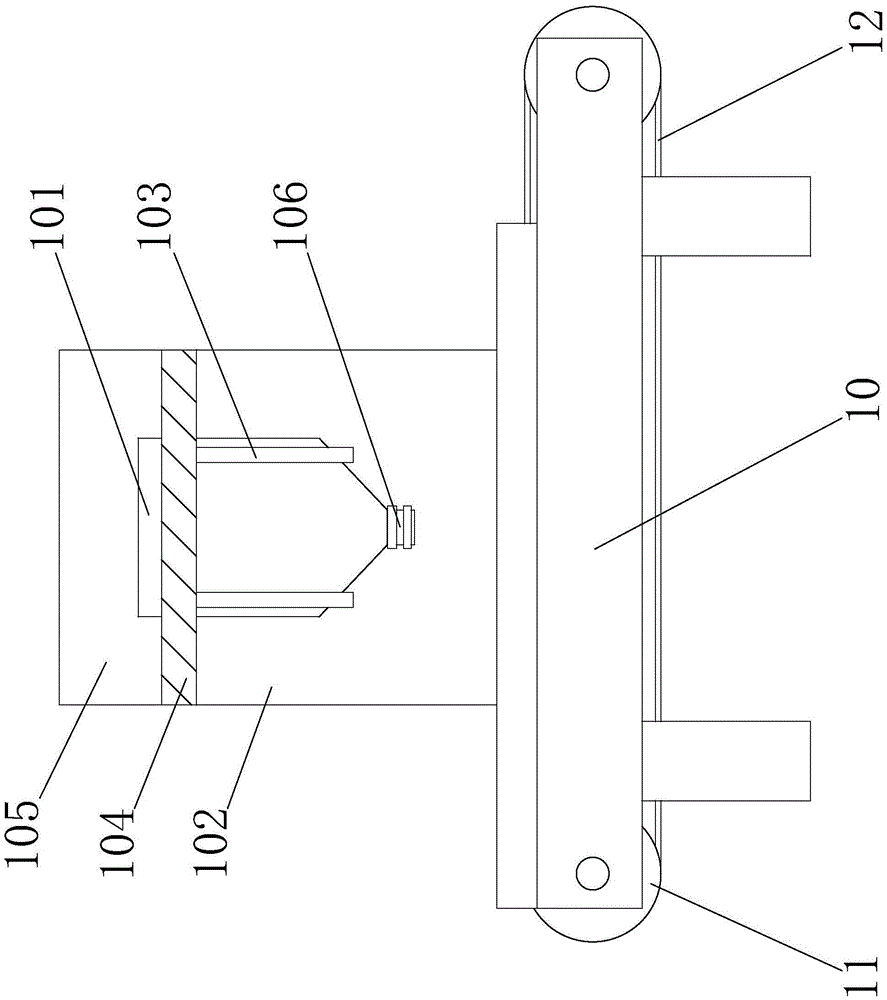

[0039] Such as Figure 1-15 As shown, the thermal insulation board compound processing line body includes the front conveyor belt device 8, the intermediate conveyor belt device 9, the mortar grouting device 1, the mortar scraping device 2, the cement base cloth output device 3, the drying device 4, and the thermal insulation board cutting device. The device 5, the movable conveying device 6, the insulation board placement frame lifting device 7, is characterized in that: the front conveyor belt device 8 and the intermediate conveyor belt device 9 are driven by a conveyor belt frame body 10, a conveyor pulley 11, a conveyor belt 12 and Conveyor belt 12 is composed of a conveyor belt driving motor, the mortar grouting device 1 is located on the front conveyor belt device 8, the mortar scraping device 2 is located between the front conveyor belt device 8 and the middle conveyor belt device 9, and the middle conveyor belt device 9 From the feed end to the discharge end, a cement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com