Gas expanded granular sludge bed anaerobic reactor

An anaerobic reactor, granular sludge technology, applied in anaerobic digestion treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of dead angle, plug flow, small gas production, etc. The degree of expansion, the reduction of hydraulic load, the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and example the present invention will be further described:

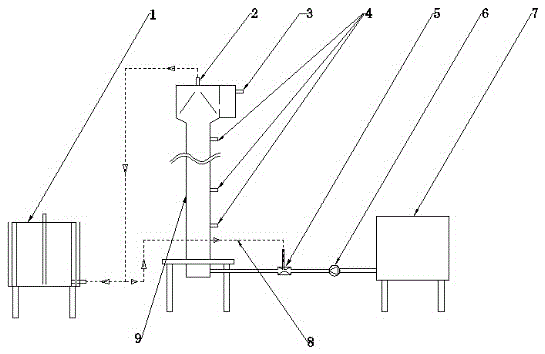

[0015] Such as figure 1 As shown, a gas-expanded granular sludge bed anaerobic reactor includes anaerobic reaction body (9), water pump (6), Venturi tube (5), biogas circulation pipeline (8), feed tank ( 7), material outlet (3), gas outlet (2), gas cabinet (1), sampling hole (4). A gas-expanded granular sludge bed anaerobic reactor of the present invention uses a water pump (6) to absorb sewage, mixes sewage and biogas through a Venturi tube (5), and then jets enter the reactor main body (9), simultaneously realizing gas And the uniform distribution of liquid, and by controlling the external circulation pipeline (8), the amount of circulating biogas can be controlled, and at the same time, the expansion degree of the granular sludge in the reactor can be controlled.

[0016] Preferably, the Venturi tube (5) is used to achieve uniform mixing of sewage and bioga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com