Self-cleaning interior-exterior two-stage robot cleaning equipment of water purifier

A technology of cleaning equipment and robots, which is applied in the direction of water/sewage multi-stage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of endangering the health of users and the breeding of bacteria in filter elements, and achieve reduced maintenance costs and pure water quality , smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following describes the present invention in detail with reference to the drawings and specific embodiments.

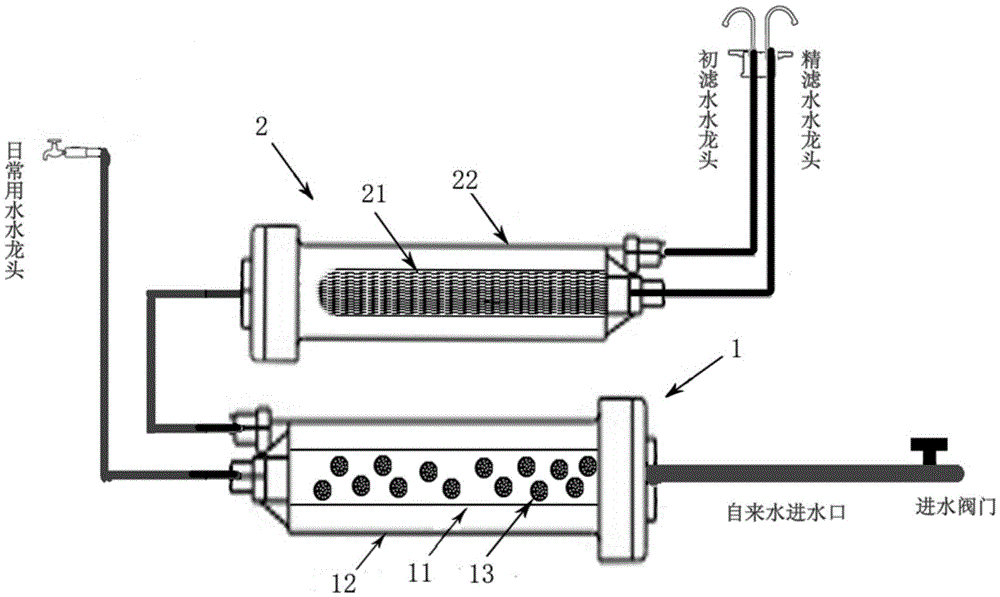

[0021] Reference figure 1 , The robot self-cleaning internal and external two-stage cleaning equipment of the water purifier of the present invention is mainly composed of two-stage filter elements, which are respectively denoted as the first-stage filter element 1 and the second-stage filter element 2.

[0022] The structure and characteristics of the two-stage filter element are described in detail below.

[0023] 1. The first stage filter

[0024] The first-stage filter element 1 is a barrel-type ceramic filter element, which is composed of a ceramic inner core 11 and a first outer cylinder 12. Among them, the two ends of the ceramic inner core 11 are respectively provided with a tap water inlet and a daily water outlet, the tap water inlet is connected with the water inlet pipe, the daily water outlet is connected with the daily water tap, and one end of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com