Hydrogenation method of butadiene extraction tail gas

A technology for butadiene and two-stage hydrogenation, which is applied in the fields of hydrogenation to hydrocarbons, organic chemistry, isomerization to hydrocarbons, etc., can solve the problem of no recycling and other problems, and achieve the effects of increasing production and significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

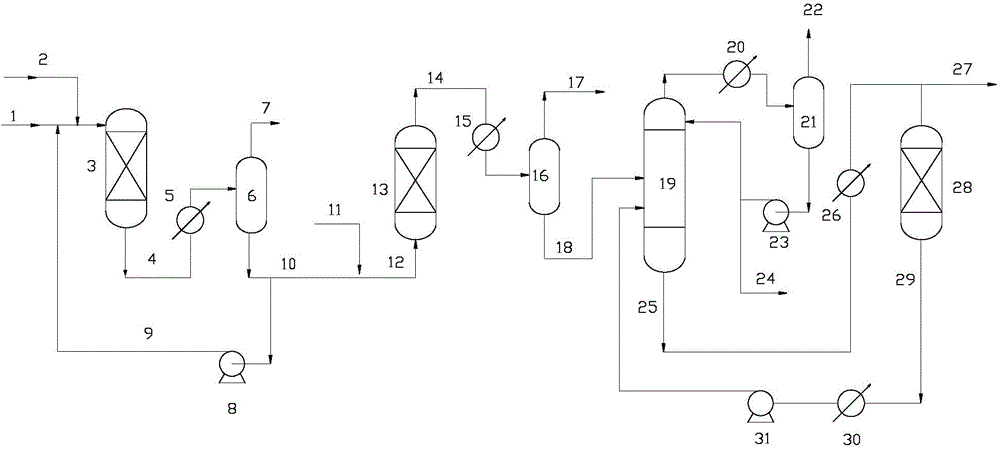

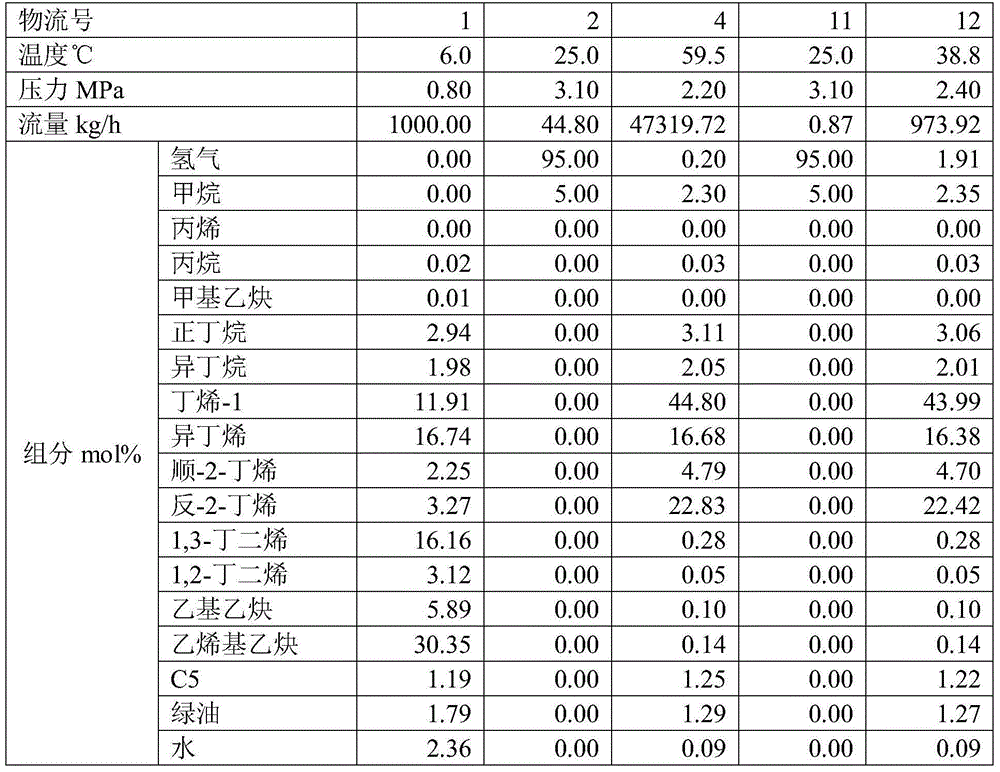

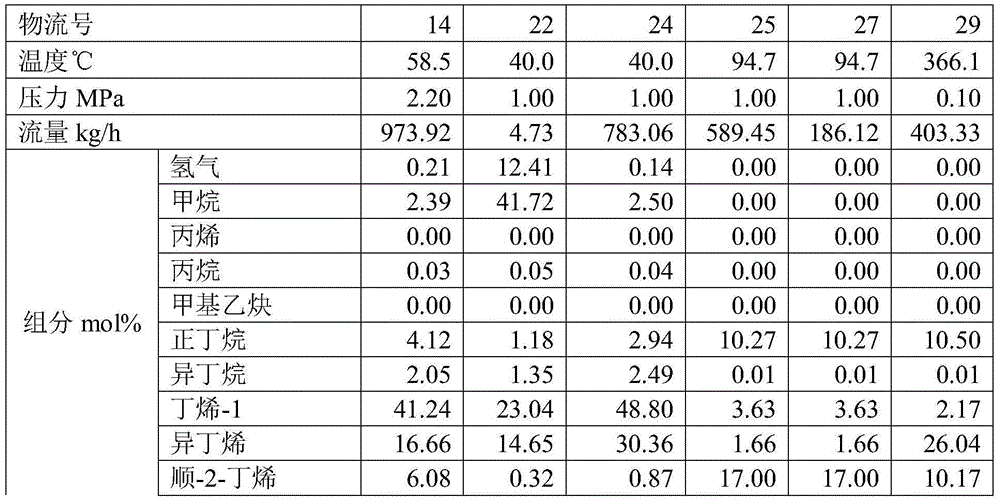

[0032] The liquefied butadiene tail gas 1 from the butadiene extraction unit, at a temperature of 30°C and a flow rate of 1000kg / h, is mixed with the 50000kg / h liquid phase 9 and 45kg / h hydrogen gas 2 from the first-stage outlet separation tank, and is sent from the first-stage reactor The upper part of 3 enters. The inlet conditions of the first-stage reactor are: temperature 40°C, pressure 2.0MPa, hydrogen / (alkyne + diene) molar ratio 1.5:1, the first-stage reaction product 4 enters the cooler 5, and enters the first-stage outlet separation tank 6 after cooling with water. Part of the liquid phase is boosted by the circulation pump 8 and mixed with the butadiene tail gas 1, and the other liquid phase material 10 enters the second-stage reactor 13, and the flow rate of the second-stage hydrogen gas 11 is 1 kg / h. The inlet conditions of the second-stage reactor 13 are: temperature 40°C, pressure 1.8MPa, hydrogen / (alkyne + diene) molar ratio 4:1, the second-stage reaction produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com