Method for extracting nano-crystalline cellulose microfiber from cotton stalk bark

A technology of nano-cellulose and cotton stalk skin, which is applied in fiber raw material processing, textiles and papermaking, etc., can solve environmental problems such as pollution, waste of resources, etc., and achieve the effects of solving environmental pollution problems, easy degradation, and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

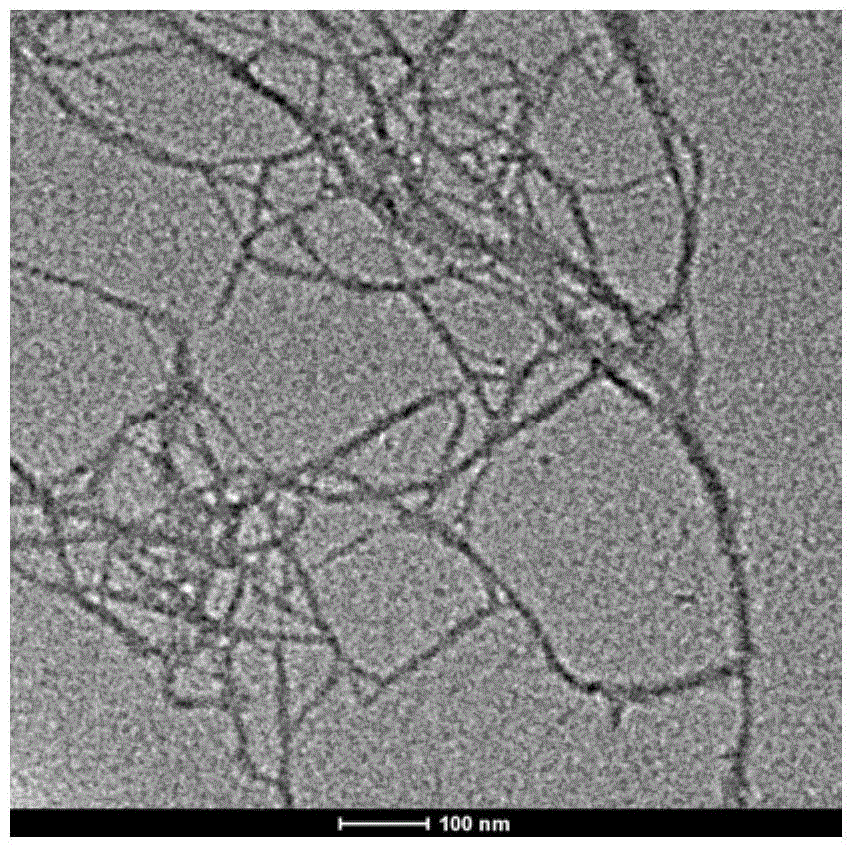

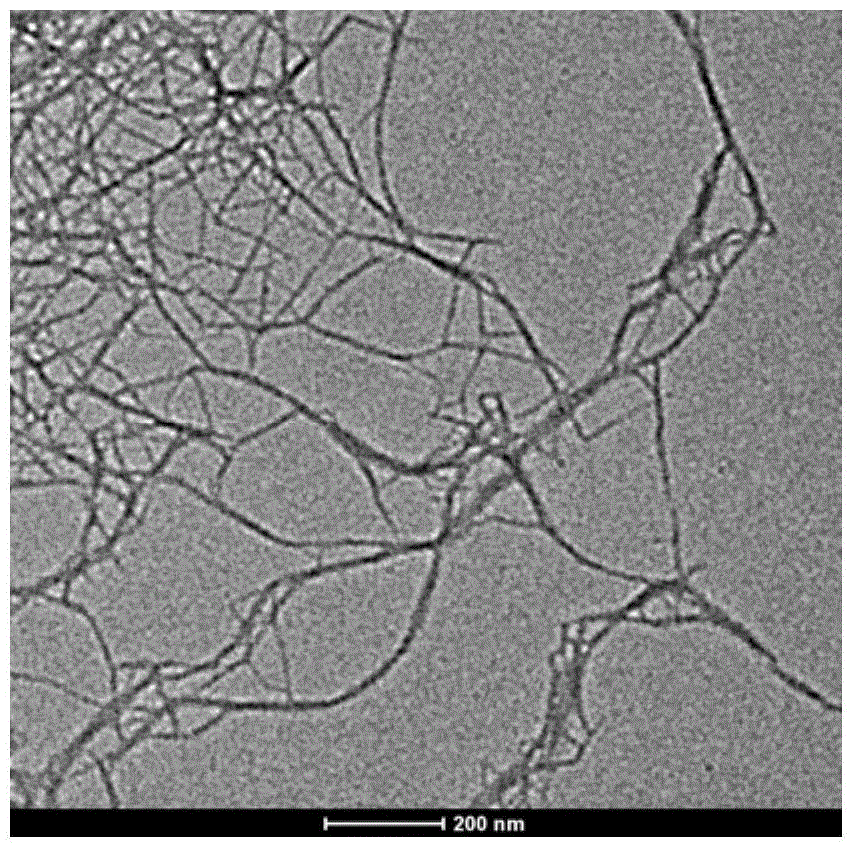

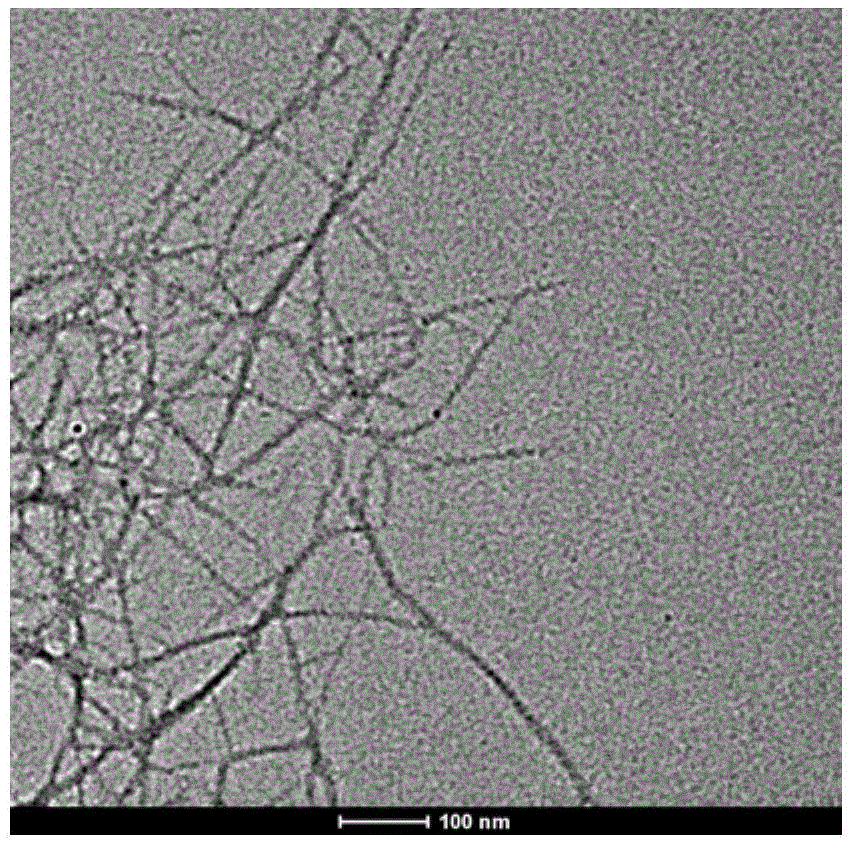

Image

Examples

Embodiment 1

[0024] Wash 15g of cotton stalk skin with water and place in 3ml / LH 2 SO 4 Boil in acid at 60°C for 2.5 hours, and the bath ratio is 1:30. Then remove the cotton stalk from the H 2 SO 4 Take it out, wash it with water, remove the outer skin of the cotton stalk skin, and then put the cotton stalk skin in 8g / LNaOH, 8ml / LH 2 o 2 Boil in the mixed solution at 70°C for 2 hours, and the bath ratio is 1:100. Remove the cotton stalk skin from the mixed solution and wash it with water, then gently tap it along the axial direction of the cotton stalk skin with a rubber hammer, beat out the pulp in the cotton stalk skin, then wash it with clean water, and repeat the beating-cleaning process 10 Second-rate. Then put the cotton stalk skin of the pulp into 12g / LNaOH, 12ml / LH 2 o 2 Boil in the mixed solution at 80°C for 1 hour, and the bath ratio is 1:100. Remove the cotton stalk skin from the mixed solution and place it in 0.5ml / LH 2 SO 4 Soak it for 10 minutes, then take out the...

Embodiment 2

[0028] Wash 15g of cotton stalk skin with water and place in 2ml / LH 2 SO 4 Boil in acid at 65°C for 2.5 hours, and the bath ratio is 1:25. Then remove the cotton stalk from the H 2 SO 4 Take it out, wash it with water and remove the outer skin of the cotton stalk skin, then put the cotton stalk skin in 5g / LNaOH, 5ml / LH 2 o 2Boil in the mixed solution at 75°C for 2 hours, and the bath ratio is 1:100. Remove the cotton stalk skin from the mixed solution and wash it with water, then gently tap it along the axial direction of the cotton stalk skin with a rubber hammer, beat out the pulp in the cotton stalk skin, then wash it with clean water, and repeat the beating-cleaning process 10 Second-rate. Then put the cotton stalk skin of the pulp into 12g / LNaOH, 12ml / LH 2 o 2 Boil in the mixed solution at 85°C for 1 hour, and the bath ratio is 1:100. Remove the cotton stalk skin from the mixed solution and place it in 0.3ml / LH 2 SO 4 Soak it for 15 minutes, then take out the c...

Embodiment 3

[0032] Wash 15g of cotton stalk skin with water and place in 4ml / LH 2 SO 4 Boil in acid at 55°C for 2.5 hours, and the bath ratio is 1:30. Then remove the cotton stalk from the H 2 SO 4 Take it out, wash it with water, remove the outer skin of the cotton stalk skin, and then put the cotton stalk skin in 10g / LNaOH, 10ml / LH 2 o 2 Boil in the mixed solution at 65°C for 2 hours, and the bath ratio is 1:100. Remove the cotton stalk skin from the mixed solution and wash it with water, then gently tap it along the axial direction of the cotton stalk skin with a rubber hammer, beat out the pulp in the cotton stalk skin, then wash it with clean water, and repeat the beating-cleaning process 10 Second-rate. Then put the cotton stalk skin of the pulp into 15g / LNaOH, 15ml / LH 2 o 2 Boil in the mixed solution at 75°C for 1 hour, and the bath ratio is 1:120. Remove the cotton stalk skin from the mixed solution and place it in 0.6ml / LH 2 SO 4 Soak it for 10 minutes, then take out t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com