Novel high-flexibility mineral insulated special cable

A mineral insulation, special cable technology, applied in the direction of insulated cables, insulated conductors, inorganic insulators, etc., can solve the problems of not easy to bend, uneven insulation distance between conductor and sheath, inconvenient for large-length production, etc., to improve bending performance, Radial distance uniform effect

Inactive Publication Date: 2016-05-18

程学武

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to overcome the shortcomings of existing mineral insulated cables that are not easy to bend, inconvenient for large-length production, and the insulation distance between the conductor and the sheath is uneven; the present invention provides a new type of high-flexibility mineral-insulated special cable. Special cables not only have the excellent properties of general mineral insulated cables, but also have excellent properties such as excellent flexibility and convenient production of any length; and are easier to manufacture

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

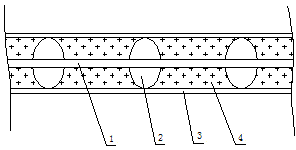

[0013] exist figure 1 Among them, the copper conductor 1 of the new high-flexibility mineral insulated special cable passes through several insulating support frames 2 composed of magnesium oxide materials, and a seamless copper sheath 3 is provided outside the copper conductor 1 and the insulating support frame 2. An insulating material composed of magnesium oxide powder 4 is filled between the sheath 3 and the copper conductor 1 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a novel high-flexibility mineral insulated special cable. The copper conductor passes through a plurality of insulated supporting frames; a metal sheath layer is arranged outside the copper conductor and the insulated supporting frames; and an inorganic powder insulated material fills space between the metal sheath layer and the copper conductor. As the non-sintered inorganic powder fills the inner part of the metal sheath layer, the bending performance of the mineral insulated cable is improved fundamentally; and the insulated supporting frames connected with the conductor can ensure the radial distance between the conductor when bent and the metal sheath is uniform.

Description

technical field [0001] The invention belongs to the technical field of special cables, and is especially suitable for use in occasions requiring high fire protection or corrosion resistance, such as nuclear power, petroleum, chemical industry, ships and high-rise buildings. Background technique [0002] In the past two decades, people have conducted extensive and in-depth research on the flame-retardant and fire-resistant properties of organic insulation or sheath materials for wires and cables, and many flame-retardant and fire-resistant cable products with superior performance have been successfully developed; but unfortunately, these organic materials Harmful gases and dense smoke will still be released during the combustion process, and it is difficult to ensure that some important electrical circuits can work normally during the fire. Mineral insulated cables (generally copper core copper sheathed magnesia insulated cables) are safety cables with excellent performance. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01B3/12H01B7/02H01B7/295

Inventor 程学武

Owner 程学武

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com