LED light source substrate and manufacturing method thereof

A technology of LED light source and manufacturing method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve the problem of poor control of the quality of wire bonding and phosphor coating, affecting the packaging yield of LED light source, and prone to problems, etc. problems, to achieve the effects of avoiding capacity bottlenecks, saving gold wire consumables, and high product yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, features and advantages of the present invention clearer, the specific implementation of the present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments. In the following description, many specific details are set forth for the convenience of The invention is fully understood, but it can be practiced in many other ways than that described. Accordingly, the present invention is not limited to the specific implementations disclosed below.

[0019] Such as Figure 1-Figure 6 Shown, a kind of manufacturing method of LED light source substrate, comprises the following steps:

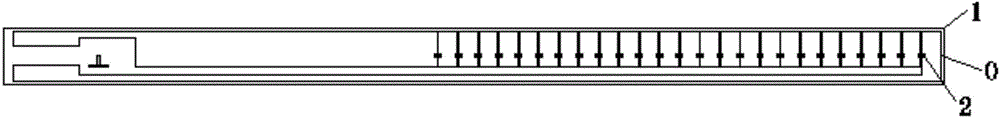

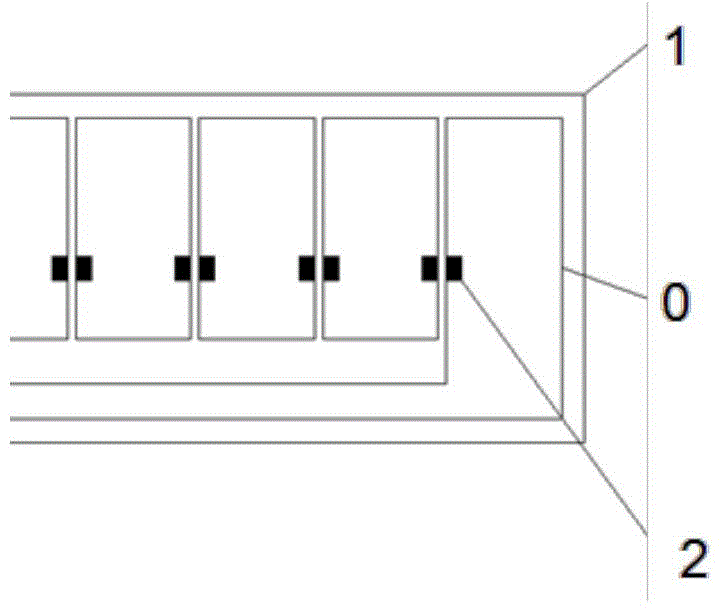

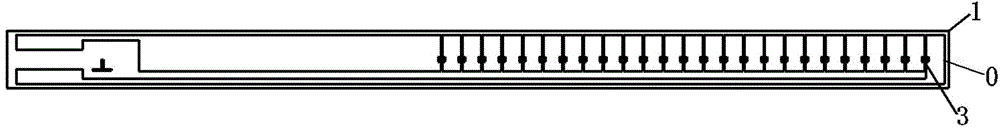

[0020] S1, printing solder paste: such as figure 1 , figure 2 As shown, on the substrate 1 with the line 0 set, the solder paste 2 is printed on the positions corresponding to the positive and negative electrodes of the LED chip, and the solder paste 2 is printed by stencil printing;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com