Intelligent transmission line ice layer reduction system

A transmission line and ice layer technology, applied in the field of intelligent transmission line ice reduction system, can solve the problems of wire rising or jumping up and down, power supply interruption, robot deicing scheme difficult to apply in large quantities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

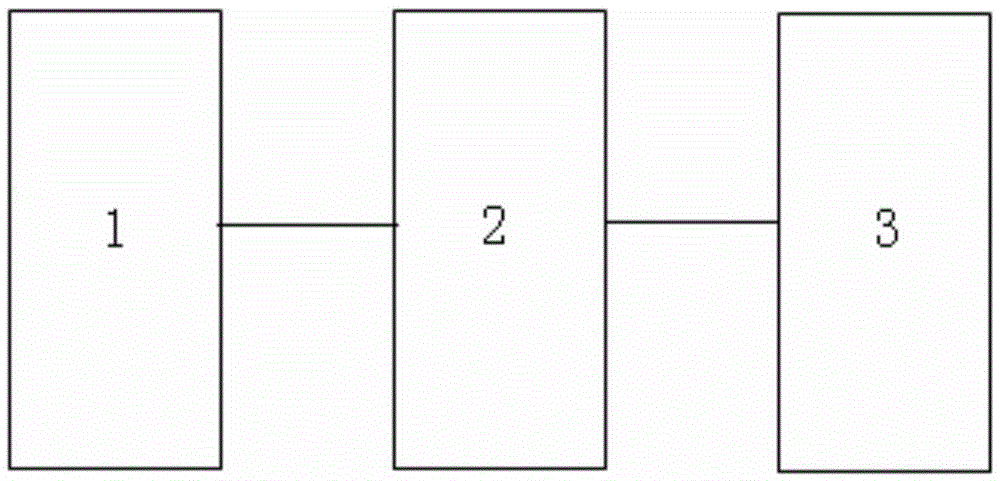

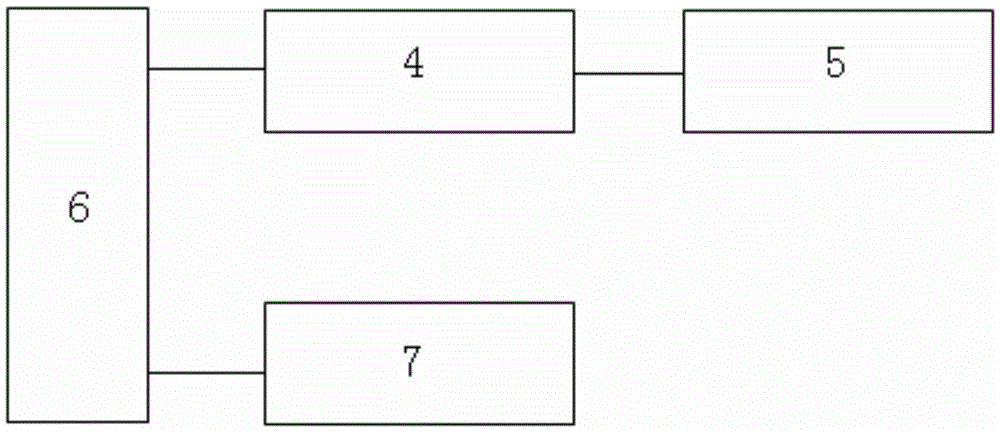

[0018] The implementation of the intelligent power transmission line ice reduction system of the present invention will be described in detail below with reference to the accompanying drawings.

[0019] The icing of transmission lines, that is, the icing of conductors, is closely related to meteorological conditions. Usually, when the temperature around the line is between -2 and -10 degrees, the relative air humidity is about 90%, heavy fog or drizzle, and the wind speed is 5 to 15m / s, it is most likely to form on the ground wire. In addition, it is also related to the structure of the conductor, the height of the suspension point of the conductor, the direction of the line, the water source of the area where the line passes, and the topography.

[0020] If you want to detect the icing of the line in advance, you must master the above relevant information, especially the changeable meteorological information. To solve the problem of line icing hazards, the main thing is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com