Loudspeaker module and manufacturing method of same

A loudspeaker module and loudspeaker technology are applied in the manufacture of loudspeaker module casings and the field of loudspeaker module casings, which can solve the problems of reduction of the effective area of the diaphragm, consistency, reduction of the speaker yield and the controllable rate of production, etc. , to achieve the effect of ensuring effective area, improving yield and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

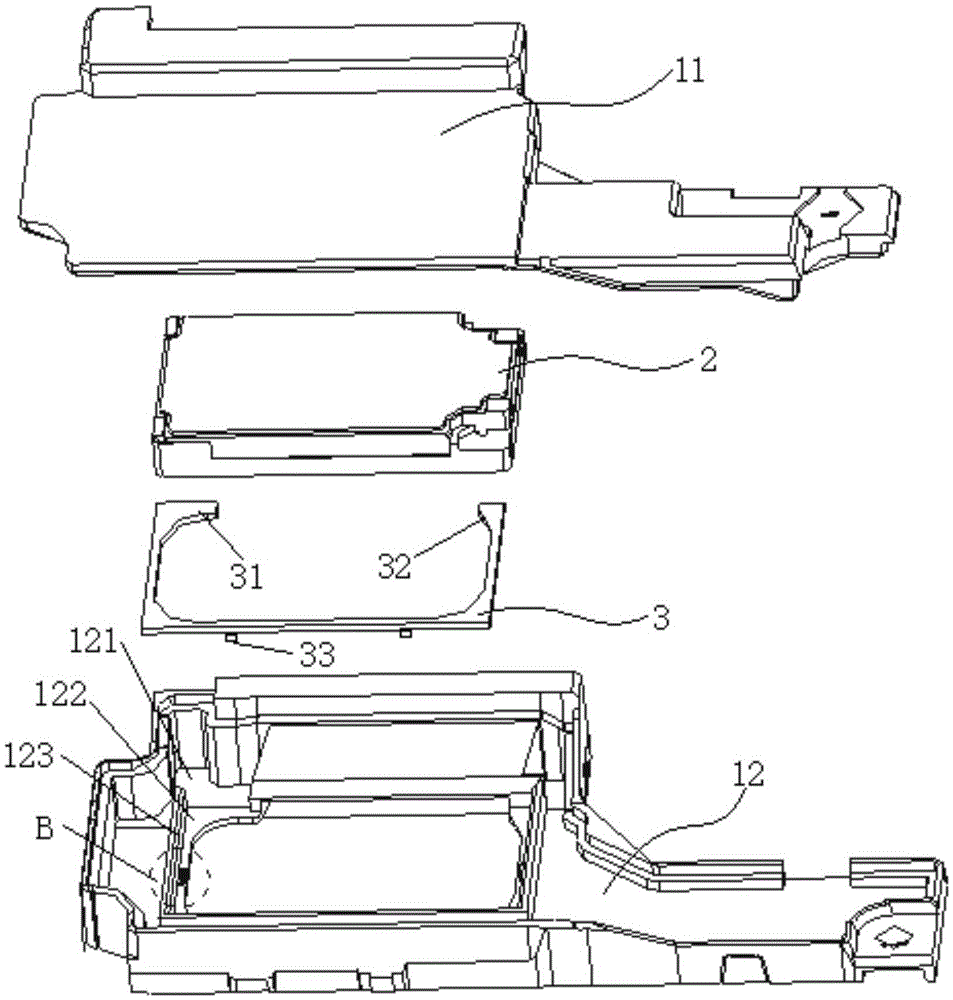

[0047] The present invention also provides a method for manufacturing a loudspeaker module, so as to achieve a better combination between the intermediate connector 3 and the loudspeaker module housing 1, Figure 5 An embodiment of the manufacturing method is shown, which specifically includes the following steps:

[0048] 1) A recess 121 and an intermediate connector platform 122 located at the bottom of the recess 121 are formed on the lower shell 12 of the speaker module housing 1 by a one-time molding process;

[0049] 2) The intermediate connector 3 is formed on the intermediate connector platform 122 in step 1) using a secondary injection molding process. The adoption of the secondary injection molding process can not only ensure the reliability of the connection between the intermediate connector 3 and the intermediate connector platform 122 It can also realize fully automatic production, which is conducive to improving production efficiency and saving human resources; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com