Cylindrical shell metal mold casting demoulding machine

A metal mold casting and demolding machine technology, which is applied to the cylindrical shell metal mold casting and demolding machine belongs to the field of post-casting treatment, and can solve the problems such as difficulty in demoulding the cylindrical shell metal mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

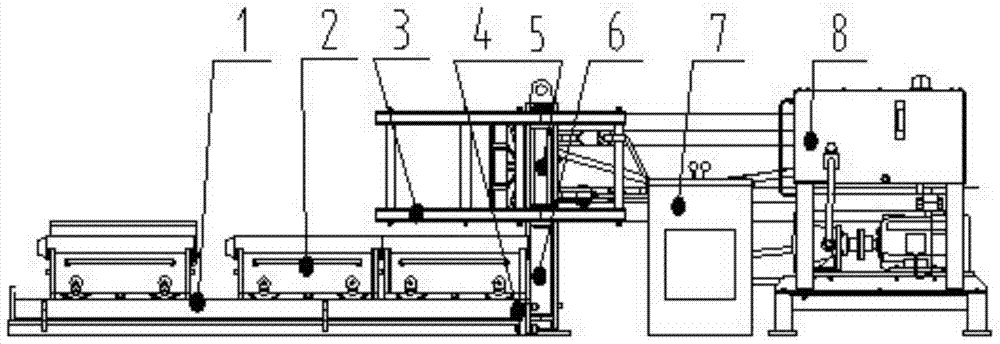

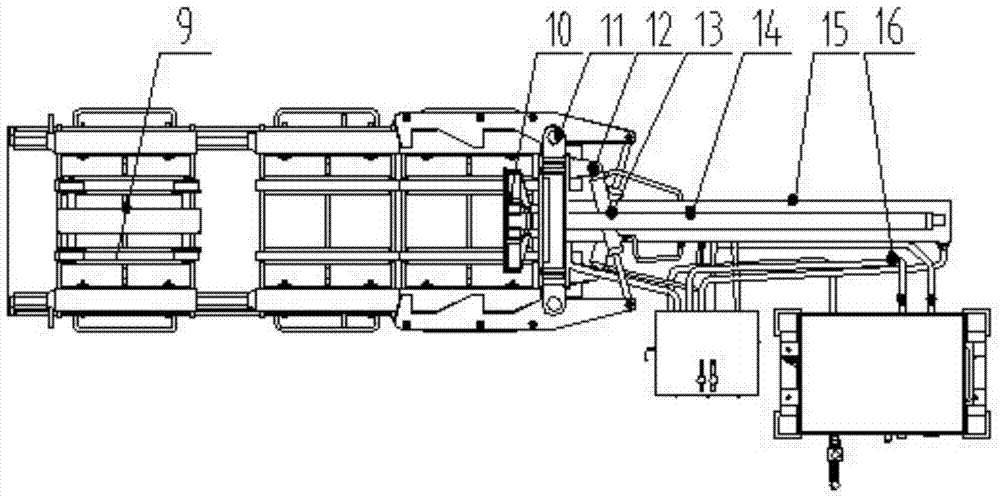

[0012] See figure 1 , figure 2 , the cylindrical shell metal mold casting stripper, the present invention is characterized in that: three carriages 2 are installed on the guide rails of the floor rail workbench 1, and a support carriage 9 is placed on the guide rail of one carriage carriage 2 on the left, The right end plate of the worktable 1 is connected to the cylinder mounting seat 6 through screws 4, and the left and right hydraulic clamping mechanisms 3 are connected to four fixing brackets 11 through two rotating shafts 5. On the other hand, the hydraulic control system 7 and the variable pump type hydraulic pump station 8 are connected with two clamping cylinders 13 and one ejecting hydraulic cylinder 15 through the hydraulic pipeline system 16. One end of the clamping cylinder 13 is hinged with the hydraulic clamping mechanism 3, and the other is hinged. One end is hinged with the fixing bracket 12, the fixing bracket 12 is welded on the right side of the oil cylind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com