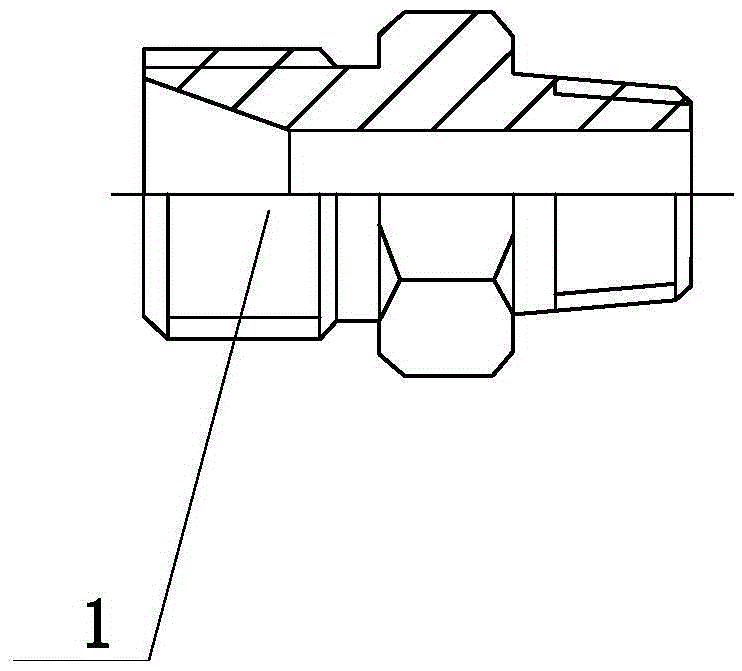

Inner hole deburring device used for screw-in type conical straight joint

A straight-through joint and deburring technology, used in grinding/polishing safety devices, machine tools suitable for grinding workpiece edges, grinders, etc., can solve problems such as hidden dangers of pipeline systems, high labor costs, and inability to control product quality. To achieve the effect of good effect, good polishing effect and high polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

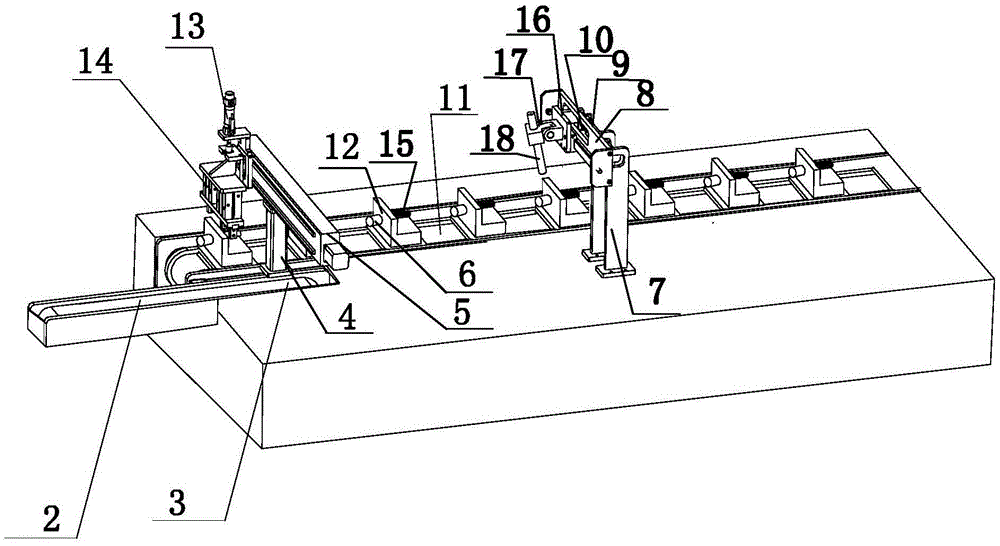

[0009] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0010] Such as Figure 1-2 As shown, a device for deburring the inner hole of a screw-in tapered straight-through joint includes a belt conveying mechanism, a feeding manipulator assembly and a polishing mechanism, and the belt conveying mechanism includes first belts 2 and second belts arranged at intervals. belt 11, and the axis where the first belt 2 is located is parallel to the axis where the second belt 11 is located; the tail end of the first belt 2 is arranged side by side with the second belt 11; the second belt 11 is provided with a plurality of bases 12 at intervals, and the base 12 is an electrically controlled permanent magnet base that can be used to absorb direct joints; a motor 6 is installed on the side plate of the base 12; The installation shaft 15 connected to the output shaft of the motor 6, and a burr brush 15 made of a non-magneti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap