Manipulator movement method and system

A motion system and manipulator technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as unproposed motion trajectories, achieve the effects of improving flexibility, improving production efficiency, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

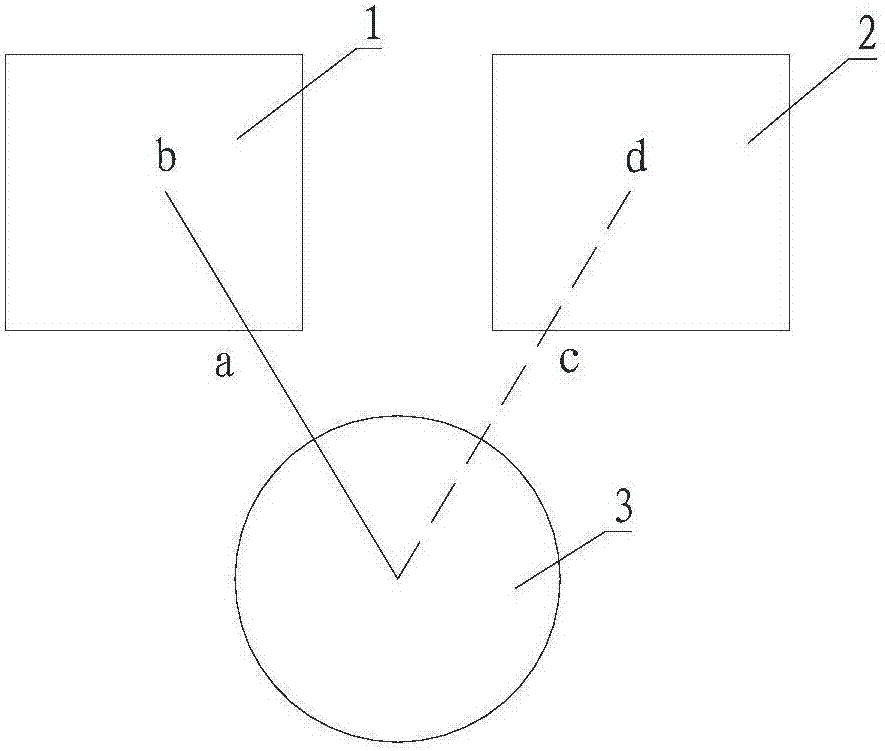

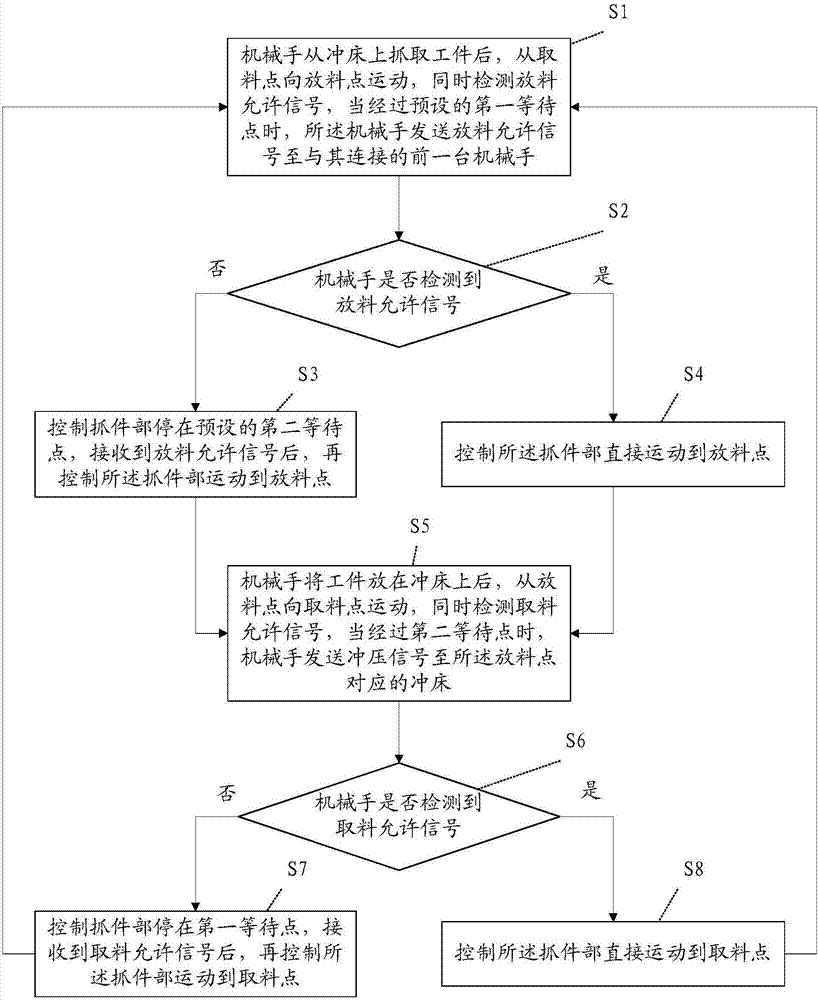

[0069] Please refer to Figure 2-3 , Embodiment 1 of the present invention is: a kind of manipulator movement method, is used for controlling the motion between manipulator loading and unloading, comprises the following steps:

[0070] S1: After the manipulator grabs the workpiece from the punch corresponding to the pick-up point, it moves from the pick-up point to the discharge point, and at the same time detects the discharge permission signal. When passing the preset first waiting point, the manipulator sends the discharge Allows the signal to the previous robot connected to it.

[0071] S2: Judging whether the manipulator detects the material discharging permission signal, if not, execute step S3, and if yes, execute step S4.

[0072] S3: Control the gripping part to stop at the preset second waiting point, and control the gripping part to move from the second waiting point to the material discharging point when the manipulator receives a material discharging permission s...

Embodiment 2

[0083] Please refer to Figure 6-7 , the second embodiment of the present invention is a manipulator motion system corresponding to the above method, including

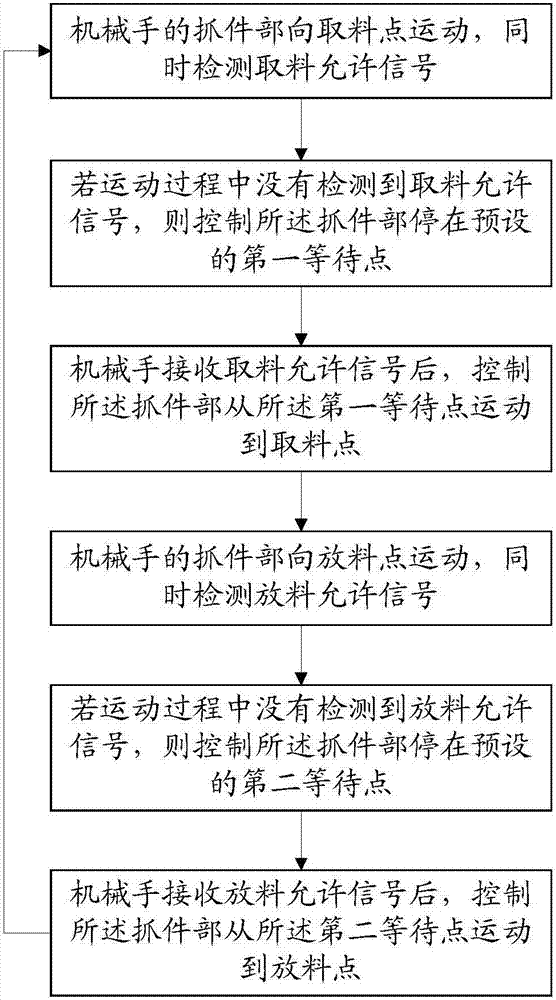

[0084] The first detection module 101 is used for the gripping part of the manipulator to move to the material retrieval point and simultaneously detect the material retrieval permission signal;

[0085] The first control module 102 is configured to control the gripping part to stop at the preset first waiting point if no material retrieving permission signal is detected during the movement;

[0086] The second control module 103 is used to control the gripping part to move from the first waiting point to the material picking point after the manipulator receives the material picking permission signal;

[0087] The second detection module 104 is used for the gripping part of the manipulator to move to the discharge point and simultaneously detect the discharge permission signal;

[0088] The third control module 105 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com