Method for preparing silicon rubber porous material based on additive manufacturing technology

A porous material and additive manufacturing technology, applied in the field of preparing silicone rubber porous materials based on additive manufacturing technology, can solve problems such as no mature technology, and achieve the effect of customization, precise control, and regulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

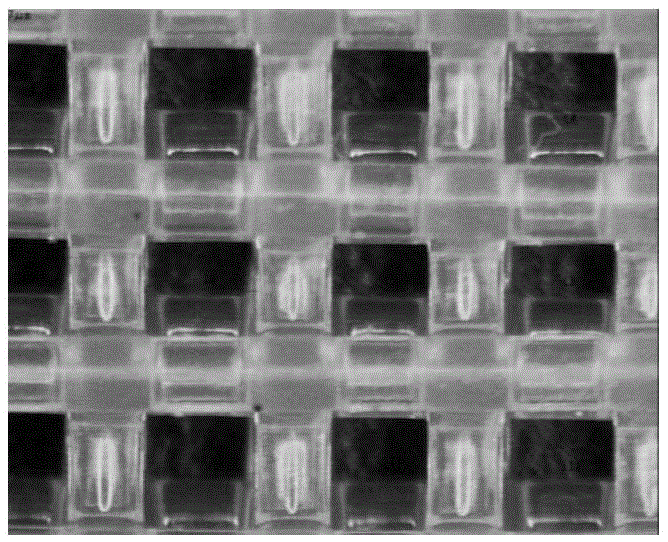

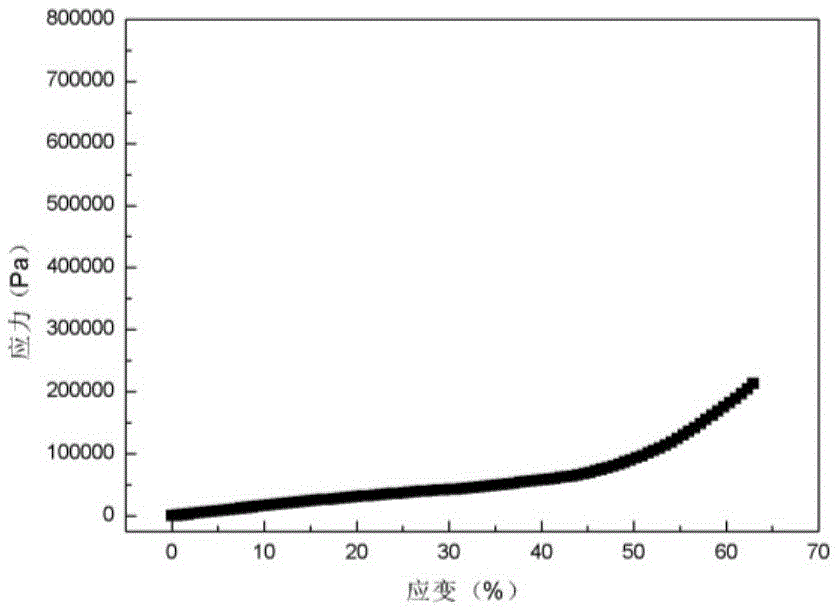

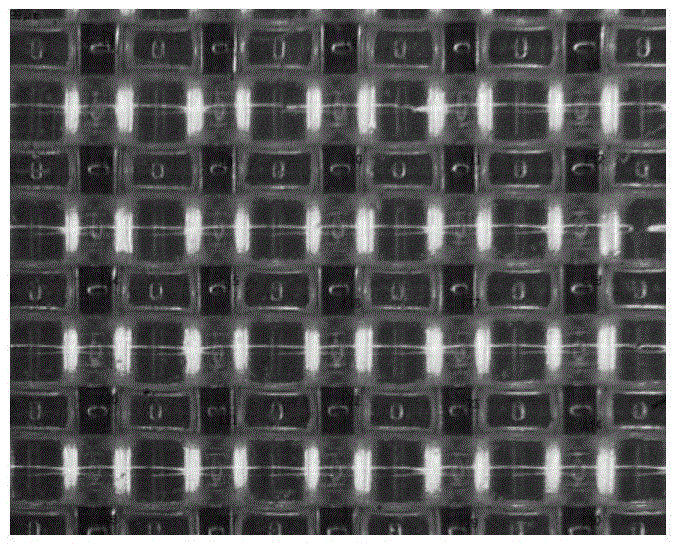

Image

Examples

Embodiment 1

[0041] 100g of viscosity is 5000mPa.s terminal vinyl polydimethylsiloxane, 15g of gas-phase process hydrophilic white carbon black is mixed evenly with a mechanical stirring device, and then 5 parts of hydrogen-containing silicone oil with a hydrogen weight fraction of 7% are added. After the mechanical stirring device is mixed evenly, add the mixed solution of 0.5g tetramethyltetravinylcyclotetrasiloxane inhibitor and platinum-vinylsiloxane complex (the mass fraction of platinum is 2×10 -3) Stir and mix evenly; put the above-mentioned glue into the barrel of the glue dispenser, seal the outlet of the barrel with a cover, then place the barrel in a defoaming machine to remove the air bubbles in the glue, and then put the glue The barrel is connected to the gas-driven valve of the dispenser and fixed on the three-axis mobile platform, and the sealing cap of the barrel is replaced with an extrusion needle with an inner diameter of 0.41mm; the pressure of the dispenser is set to 3...

Embodiment 2

[0043] Mix 100g of hydroxyl-terminated polydimethylsiloxane with a viscosity of 10000mPa.s and 40g of gas-phase hydrophobic silica with a mechanical stirring device, then add 5 parts of tetrapropoxysilane, and mix with a mechanical stirring device , add 0.5 parts of dibutyltin dilaurate, stir evenly; put the above rubber material into the barrel of the glue dispenser, seal the discharge port of the barrel with a cap, then place the barrel in a defoaming machine to remove the glue Bubbles in the material, then connect the barrel with the gas-driven valve of the dispenser and fix it on the multi-axis mobile platform, replace the barrel sealing cap with an extrusion needle with an inner diameter of 0.46mm; set the pressure of the dispenser to 550kPa, Input the coordinate parameters of the mobile platform running on each layer, start the equipment and run the program, so that the mobile platform will run according to the preset program in the three coordinate directions of x, y, an...

Embodiment 3

[0045] Mix 100g of terminal vinylmethylphenyl silicone rubber with a viscosity of 2500mPa.s, 10g of fumed hydrophilic silica, and 30g of fumed hydrophobic silica, and then add 10 parts of hydrogen containing 3.5% Mix the hydrogen silicone oil evenly, and finally add 0.5g of tetramethyltetravinylcyclotetrasiloxane and 0.1g of platinum catalyst with a mass fraction of 1% of Pt and mix evenly; Seal the discharge port of the material cylinder, then place the material cylinder in the degassing machine to remove the air bubbles in the rubber material, then connect the material cylinder with the gas-driven valve of the glue dispenser and fix it on the multi-axis mobile platform, and put the material Replace the cylinder sealing cap with an extrusion needle with an inner diameter of 0.65mm; set the pressure of the dispenser to 300kPa, input the coordinate parameters of the mobile platform running on each layer, start the equipment and run the program, so that the mobile platform is in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com