Carbide slag preparation of industrial sodium hydroxide reaction device

A sodium hydroxide and reaction device technology, applied in the direction of alkali metal hydroxides, etc., can solve the problems of lack, low concentration of sodium hydroxide solution, low reaction efficiency, etc., and achieve the effects of good effect, reduced pollution impact, and unique structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

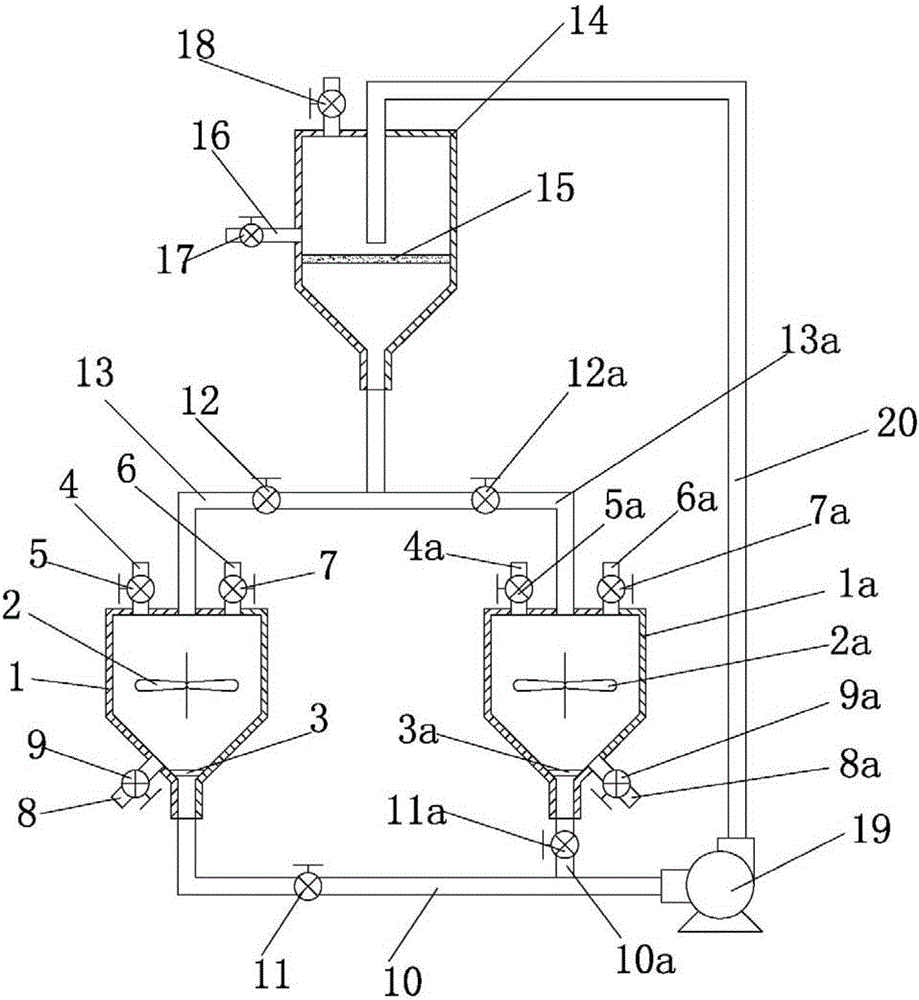

[0021] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] Depend on figure 1 Given, the present invention comprises a concentration column, a first exchange reactor and a second exchange reactor, the first exchange reactor and the second exchange reactor have the same structure, both of which include a shell, the shell is a hollow structure, and the shell There is a liquid outlet at the bottom, a filter cloth is arranged on the liquid outlet, an agitator is arranged in the casing above the filter cloth, a feeding port and a water feeding port are respectively arranged on the upper part of the casing, the first exchange reactor and the second exchange reactor The liquid outlets are respectively connected to the inlet of the alkali-resistant pump 19 through the first circulation pipeline 10 and the second circulation pipeline 10a. The concentration column includes a shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com