Building mortar and preparation method and construction application thereof

A mortar and construction technology, applied in the field of ready-mixed mortar, can solve the problems of single variety and function, and achieve the effects of ensuring safety, high negative ion production, and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

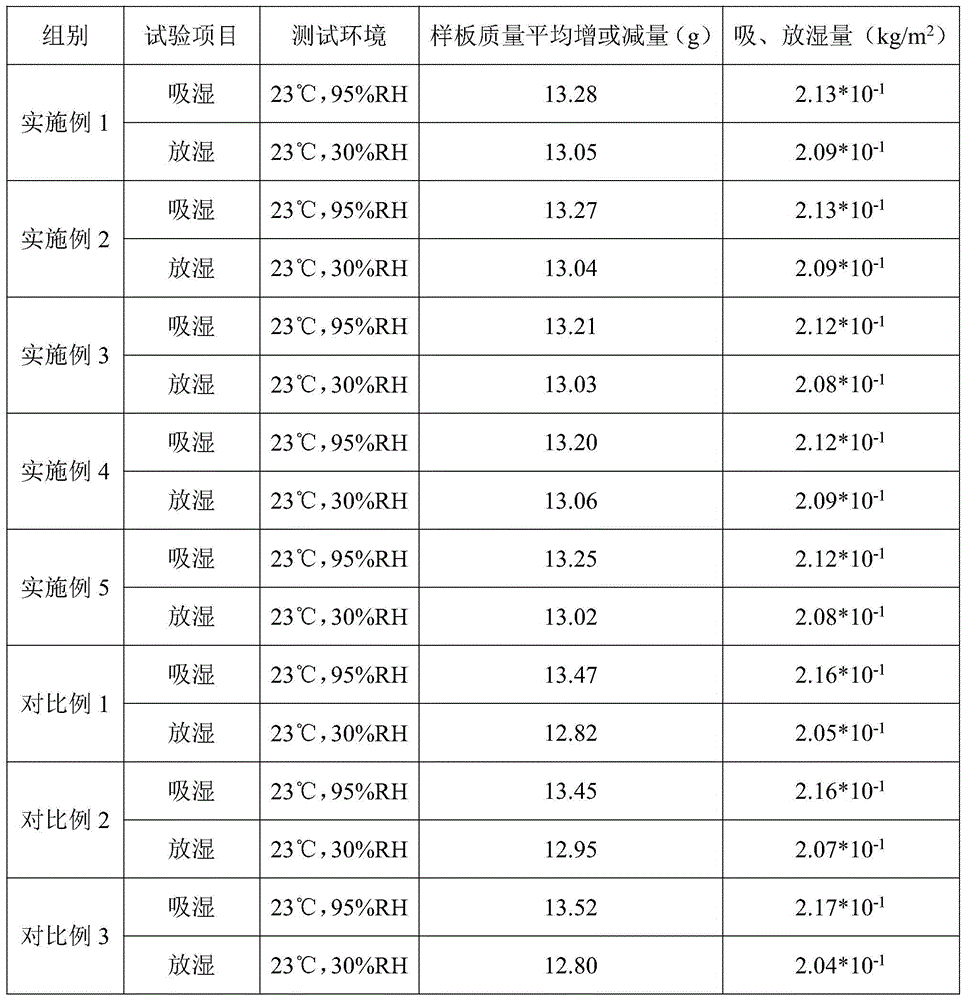

Embodiment 1

[0021] In the embodiment of the present invention, a construction mortar is composed of the following raw materials according to parts by weight: 8 parts of Longzi, 1 part of Uncaria, 22 parts of quartz sand, 6 parts of talcum powder, 65 parts of calcium sulfate, lignin sulfonate Salt 2 parts.

[0022] After washing Longzi and Uncaria with water to remove impurities, add absolute ethanol three times the mass of the two, stir at a temperature of 58°C until the absolute ethanol evaporates to dryness, and then add acetic acid equal to the mass of the two, Stir at a temperature of 50°C until the acetic acid is evaporated to dryness; then freeze-dry the acetic acid-treated Longzi and Uncaria at a temperature of -40°C and a vacuum of 25Pa, and freeze-dry the dried Longzi, Uncaria is ground, passed through a 40-mesh sieve, and then ultrafinely pulverized at -10°C for 10 minutes to obtain pretreated dragon fruit and uncaria. Dry the quartz sand until the moisture content is below 0.3...

Embodiment 2

[0024] In the embodiment of the present invention, a construction mortar is composed of the following raw materials in parts by weight: 15 parts of Longzi, 5 parts of Uncaria, 28 parts of quartz sand, 10 parts of talcum powder, 73 parts of calcium sulfate, lignin sulfonate Salt 5 parts.

[0025] After washing Longzi and Uncaria with water to remove impurities, add absolute ethanol 4 times the mass of the two, stir at 62°C until the absolute ethanol evaporates to dryness, then add acetic acid twice the mass of the two, Stir at a temperature of 53°C until the acetic acid is evaporated to dryness; then freeze-dry the acetic acid-treated Longzi and Uncaria at a temperature of -38°C and a vacuum of 30Pa, and freeze-dry the dried Longzi, Uncaria is ground, passed through a 60-mesh sieve, and then ultrafinely pulverized at -10°C for 12 minutes to obtain pretreated Longzi and Uncaria. Dry the quartz sand until the moisture content is below 0.3%, crush it, and pass through a 100-mesh ...

Embodiment 3

[0027] In the embodiment of the present invention, a construction mortar is composed of the following raw materials in parts by weight: 10 parts of dragon fruit, 2 parts of uncaria, 24 parts of quartz sand, 7 parts of talcum powder, 67 parts of calcium sulfate, lignin sulfonate Salt 3 parts.

[0028] After washing Longzi and Uncaria with water to remove impurities, add 3.5 times the mass of absolute ethanol, stir at 60°C until the absolute alcohol is evaporated to dryness, and then add 1.5 times the mass of acetic acid, Stir at a temperature of 52°C until the acetic acid is evaporated to dryness; then freeze-dry the acetic acid-treated Longzi and Uncaria at a temperature of -39°C and a vacuum of 28Pa, and freeze-dry the dried Longzi, Uncaria is ground, passed through a 60-mesh sieve, and then ultra-finely pulverized at -10°C for 11 minutes to obtain pretreated dragon fruit and uncaria. Dry the quartz sand until the moisture content is below 0.3%, crush it, and pass through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com