Production method for color-changing engraved-design archaized brick

A production method and technology of antique tiles, applied in the field of antique tiles, can solve the problems of lack of glazed texture changes, etc., and achieve the effect of colorful colors, rich colors, and clear and vivid surface textures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Preparation of yellow glaze:

[0022] Mix 55% feldspar, 30% quartz, 10% calcite, 3% talc, and 2% zirconium vanadium yellow material to obtain a mixture by mass percentage, and then add 0.4% of the mass of the mixture to the mixture Sodium tripolyphosphate and 1% CMC are mixed evenly, finely ground to 250 mesh, and the specific gravity of the prepared glaze slurry is 1.6-1.7g / cm 3 get yellow glaze;

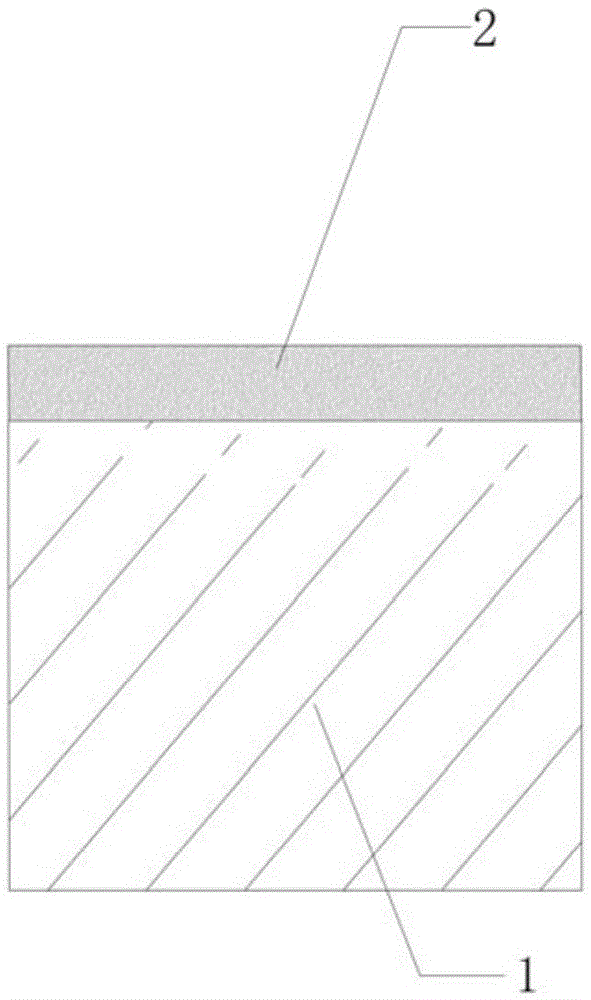

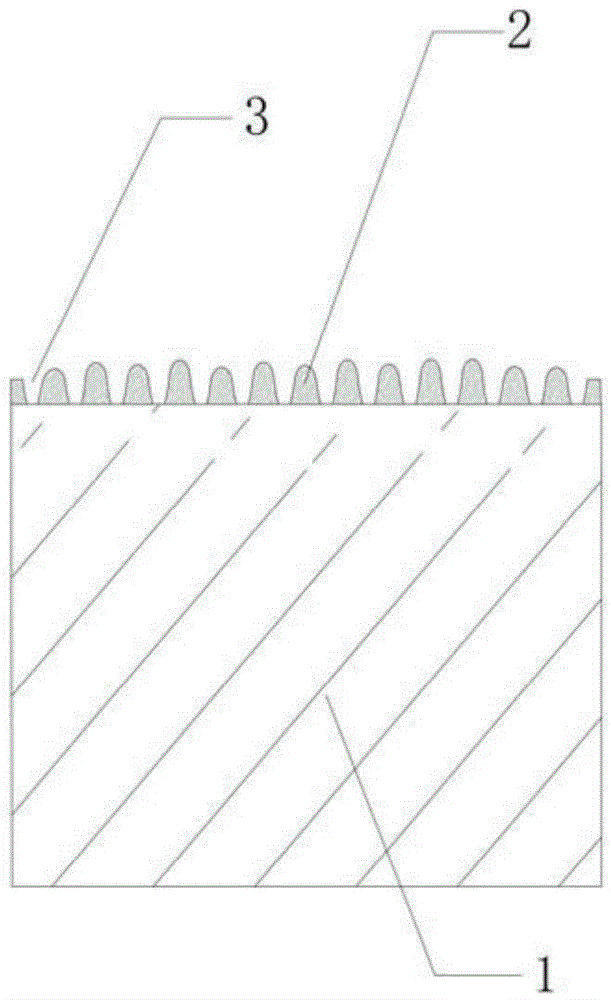

[0023] 2) Apply the glaze slurry evenly on the green body 1 to form the glaze surface 2 (see figure 1 ), then carry out the pick-up process to obtain the sample 3 after pick-up glaze (see figure 2 ), enter the kiln and raise the temperature to 1150°C under a reducing atmosphere, keep it warm for 20 minutes, and cool naturally to obtain yellow glaze pattern tiles;

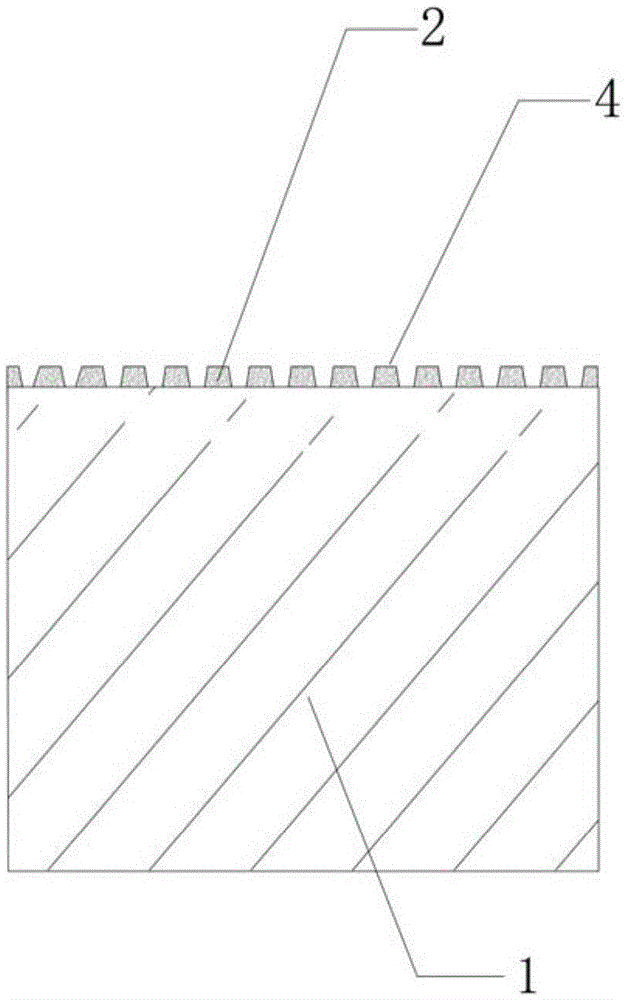

[0024] 3) Use a polishing machine to polish and polish the surface of the yellow glaze pattern tile to obtain the semi-finished product 4 of the concave-convex pattern tile (see image 3 );

[0025] 4) Us...

Embodiment 2

[0027] 1) Preparation of yellow glaze:

[0028] Mix 60% feldspar, 20% quartz, 10% calcite, 5% talc, and 5% zirconium vanadium yellow material to obtain a mixture by mass percentage, and then add 0.4% of the mass of the mixture to the mixture Sodium tripolyphosphate and 1% CMC are mixed evenly, finely ground to 250 mesh, and the specific gravity of the prepared glaze slurry is 1.6-1.7g / cm 3 get yellow glaze;

[0029] 2) Apply the glaze slurry evenly on the green body 1 to form the glaze surface 2 (see figure 1 ), then carry out the pick-up process to obtain the sample 3 after pick-up glaze (see figure 2 ), enter the kiln and raise the temperature to 1200°C under a reducing atmosphere, keep it warm for 15 minutes, and cool naturally to obtain yellow glaze pattern tiles;

[0030] 3) Use a polishing machine to polish and polish the surface of the yellow glaze pattern tile to obtain the semi-finished product 4 of the concave-convex pattern tile (see image 3 );

[0031] 4) Us...

Embodiment 3

[0033] 1) Preparation of yellow glaze:

[0034] Mix 70% of feldspar, 20% of quartz, 5% of calcite, 2% of talc, and 3% of zirconium vanadium yellow material to obtain a mixture by mass percentage, and then add 0.4% of the mass of the mixture to the mixture Sodium tripolyphosphate and 1% CMC are mixed evenly, finely ground to 250 mesh, and the specific gravity of the prepared glaze slurry is 1.6-1.7g / cm 3 get yellow glaze;

[0035] 2) Apply the glaze slurry evenly on the green body 1 to form the glaze surface 2 (see figure 1 ), then carry out the pick-up process to obtain the sample 3 after pick-up glaze (see figure 2 ), enter the kiln and raise the temperature to 1250°C under a reducing atmosphere, keep it warm for 10 minutes, and cool naturally to obtain yellow glaze pattern tiles;

[0036] 3) Use a polishing machine to polish and polish the surface of the yellow glaze pattern tile to obtain the semi-finished product 4 of the concave-convex pattern tile (see image 3 ); ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com