Variable-color engraved archaized tile and preparation method

An antique brick and yellow technology, which is applied in the field of color-changing antique bricks and its preparation, can solve the problems of lack of glaze texture changes, achieve the effect of three-dimensionality and fidelity enhancement, clear and vivid surface texture, and increase detail changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

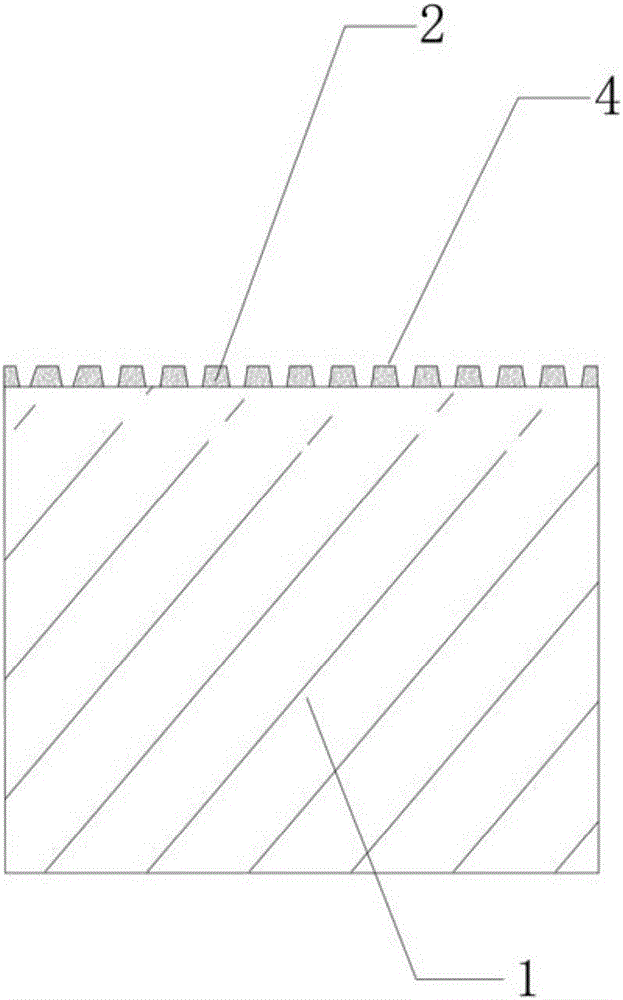

[0024] The invention provides a preparation method of color-changing anti-pattern bricks. Firstly, the prepared yellow glaze is applied on the body, and then after the process of de-patterning, it is put into a kiln and heated to the firing temperature under a reducing atmosphere. Heat preservation for a certain period of time, after natural cooling, the surface of the fired tiles is polished and polished to obtain a semi-finished product with concave-convex pattern tiles, and then evenly sprayed with a nano-silicon oxide photonic crystal film, and then heat-treated again to prepare it.

[0025] The preparation of the yellow glaze is as follows: firstly, in parts by mass, 55-70 parts of feldspar, 20-30 parts of quartz, 5-10 parts of calcite, 1-5 parts of talc and 2-5 parts of zirconium vanadium yellow material are uniformly mixed to obtain Mixed material, then add sodium tripolyphosphate and CMC to the mixed material and mix evenly, finely grind to 250 mesh, and prepare the spe...

Embodiment 1

[0036] 1) Preparation of yellow glaze:

[0037] By mass percentage, mix 55% feldspar, 30% quartz, 10% calcite, 3% talc, and 2% zirconium vanadium yellow material to obtain a mixture, and then add 0.4% of the mixture to the mixture. 1% sodium tripolyphosphate and 1% CMC are mixed evenly, finely ground to 250 mesh, and the specific gravity of the prepared glaze slurry is 1.6-1.7g / cm 3 , to obtain yellow glaze slurry;

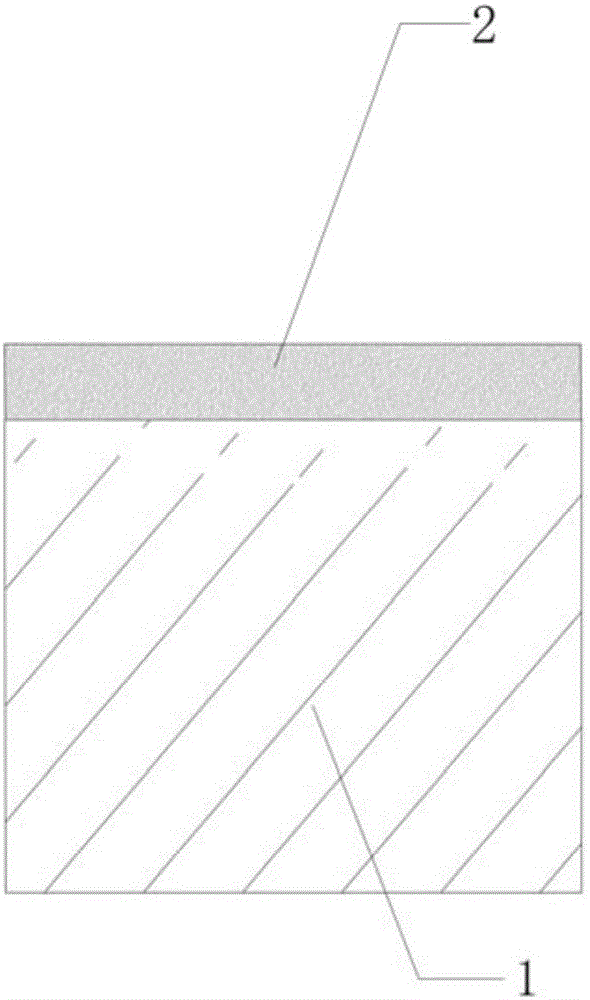

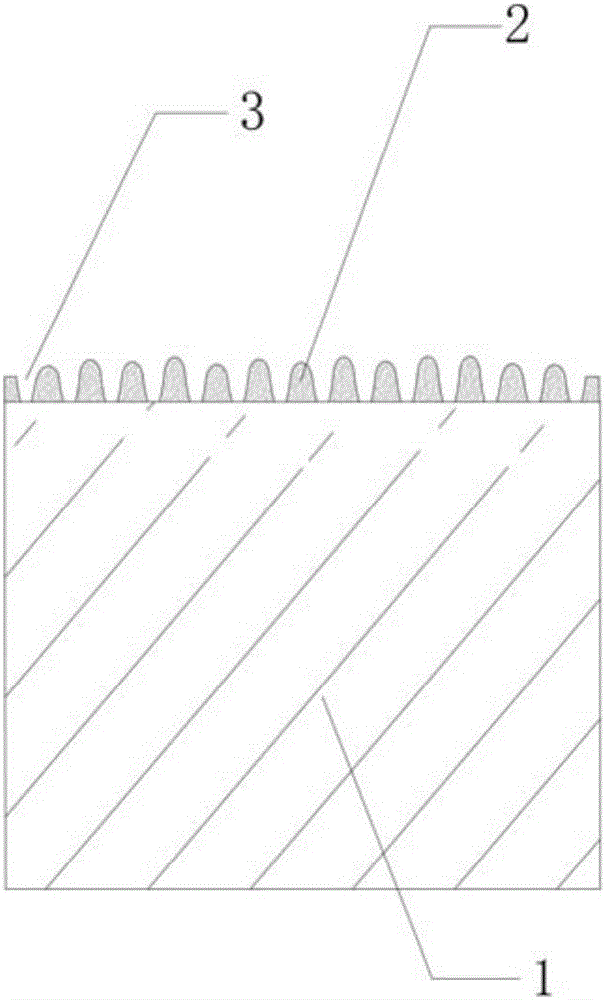

[0038] 2) see figure 1 , the glaze slurry is evenly applied on the green body 1 to form a glazed surface 2, and patterns are drawn on the glazed body glazed surface of the yellow glaze, and then the pattern removal process is carried out to obtain the sample 3 after the glaze removal (see figure 2 ), put into the kiln and raise the temperature to 1150°C in a reducing atmosphere, keep it warm for 20 minutes, and cool naturally to obtain yellow glaze pattern tiles; the flower picking process is to use the traditional method of Yaozhou kiln flower picking porcelai...

Embodiment 2

[0043] 1) Preparation of yellow glaze:

[0044] By mass percentage, mix 60% feldspar, 20% quartz, 10% calcite, 5% talc, and 5% zirconium vanadium yellow material to obtain a mixture, and then add 0.4% of the mixture to the mixture. 1% sodium tripolyphosphate and 1% CMC are mixed evenly, finely ground to 250 mesh, and the specific gravity of the prepared glaze slurry is 1.6-1.7g / cm 3 , to obtain yellow glaze slurry;

[0045] 2) Apply the glaze slurry evenly on the green body 1 to form the glaze surface 2 (see figure 1 ), draw patterns on the body glaze surface of the yellow glaze, and then carry out the deglazing process to obtain the sample 3 after deglazing (see figure 2 ), enter the kiln and raise the temperature to 1200°C under a reducing atmosphere, keep it warm for 15 minutes, and cool naturally to obtain yellow glaze pattern tiles; go;

[0046] 3) Use a polishing machine to polish and polish the surface of the yellow glaze pattern tile to obtain the semi-finished pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com