Method for fractionating mango kernel fat by virtue of solvent

A solvent extraction and mango technology, applied in the field of oil processing, can solve the problems of reduced flexibility and corresponding efficiency and benefits, hidden dangers to operators' health, consumption of large steam energy, etc., to facilitate the promotion and safety of large-scale industrialization. High, steam reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

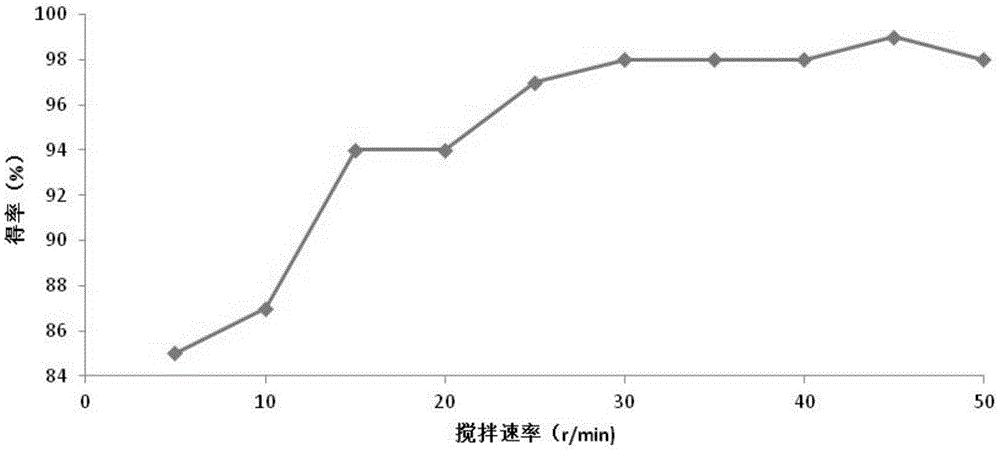

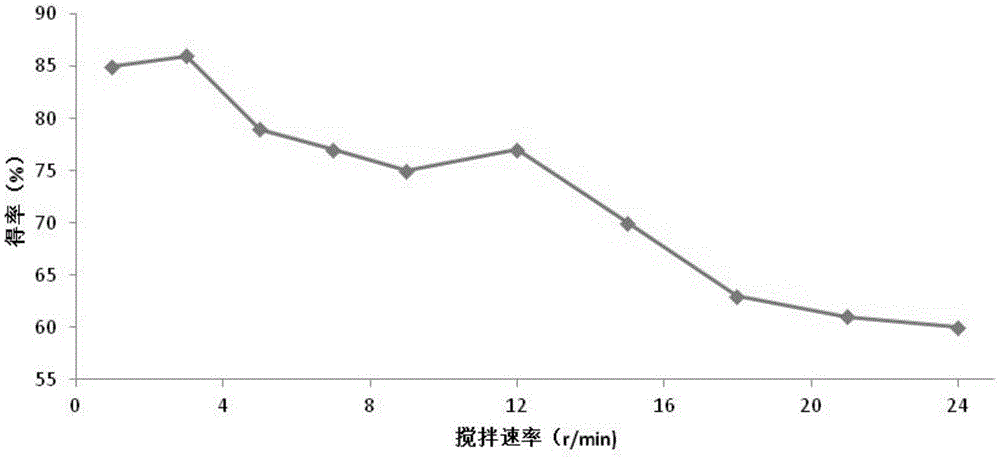

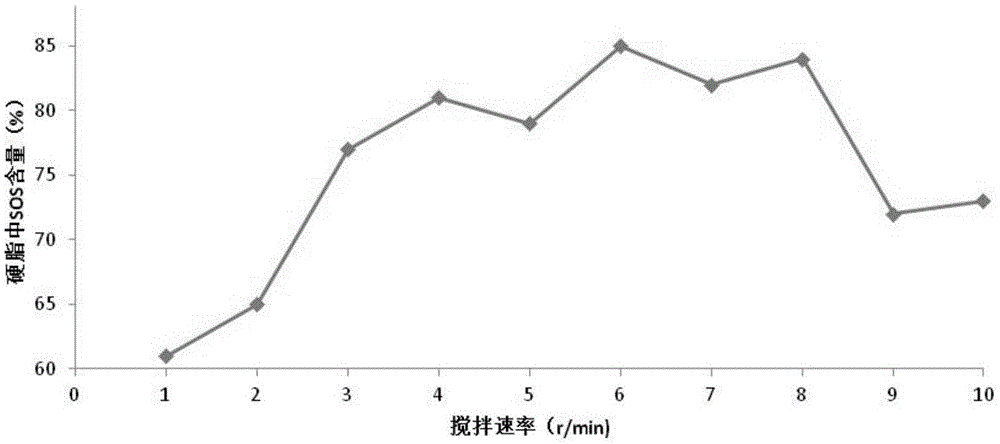

[0033] Methylpentane, wherein, 2-methylpentane: 3-methylpentane is 3:1, and the mass percent of other C6 alkanes<8%, its polarity is slightly greater than symmetrical triglyceride, and can selectively These triglycerides are crystallized, the solvent is mixed with mango kernel butter at 6:1, and the mixed oil is heated to 50°C at a stirring rate of 65r / min to destroy all crystals in the system; the first fraction is extracted at 25r / min At a stirring rate of 1.8°C / min, the temperature of the mixed oil was lowered to 7°C at a cooling rate of 1.8°C / min, and crystallized at a constant temperature for 9 hours to obtain a mixed oil with stearin removed, with a yield of 93% (accounting for the initial raw material, the same below); the second stage Fractional extraction, at a stirring rate of 9r / min, the temperature of the mixed oil after stearin removal was reduced to -12°C at a cooling rate of 1.0°C / min, crystallized at a constant temperature for 6h, and the obtained stearin was di...

Embodiment 2

[0034] Embodiment 2 (comparative example):

[0035] The traditional fractionation solvent n-hexane and mango kernel fat are mixed at a ratio of 6:1, and the mixed oil is heated to 50°C at a stirring rate of 65r / min to destroy all crystals in the system; Under the speed, the temperature of the mixed oil was lowered to 7°C at a cooling rate of 1.8°C / min, and crystallized at a constant temperature for 9 hours to obtain a mixed oil with stearin removed, with a yield of 89% (accounting for the initial raw material, the same below); the second fraction extracted , at a stirring rate of 9r / min, the temperature of the mixed oil after removal of stearin was reduced to -12°C at a cooling rate of 1.0°C / min, crystallized at a constant temperature for 6h, and the obtained stearin was distilled under reduced pressure (absolute pressure 350Pa, indirect steam 95°C, direct steam 125°C) to recover n-hexane, which is secondary stearin (POS content is 11%, SOS content is 43%), and the yield is 72...

Embodiment 3

[0039] Methylpentane, mainly containing 2-methylpentane, the mass percentage of other C6 alkanes < 6%, its polarity is slightly larger than that of symmetrical triglycerides, and these triglycerides can be selectively crystallized. The solvent is mixed with mango kernels Grease was mixed at a ratio of 5:1, and the temperature of the mixed oil was raised to 50°C at a stirring rate of 75r / min to destroy all crystals in the system; The cooling rate lowers the temperature of the mixed oil to 10°C, and crystallizes at a constant temperature for 10 hours to obtain a mixed oil with stearin removed, with a yield of 95% (accounting for the initial raw material, the same below); the second fraction is extracted at a stirring rate of 10r / min , at a cooling rate of 1.2°C / min, the temperature of the mixed oil after removal of stearin was reduced to -10°C, crystallized at a constant temperature for 5 hours, and the obtained stearin was recovered by vacuum distillation (absolute pressure 300P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com