Vacuum coating high-speed constant coiling tension apparatus and control method thereof

A technology of vacuum coating and winding tension, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., and can solve problems such as high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

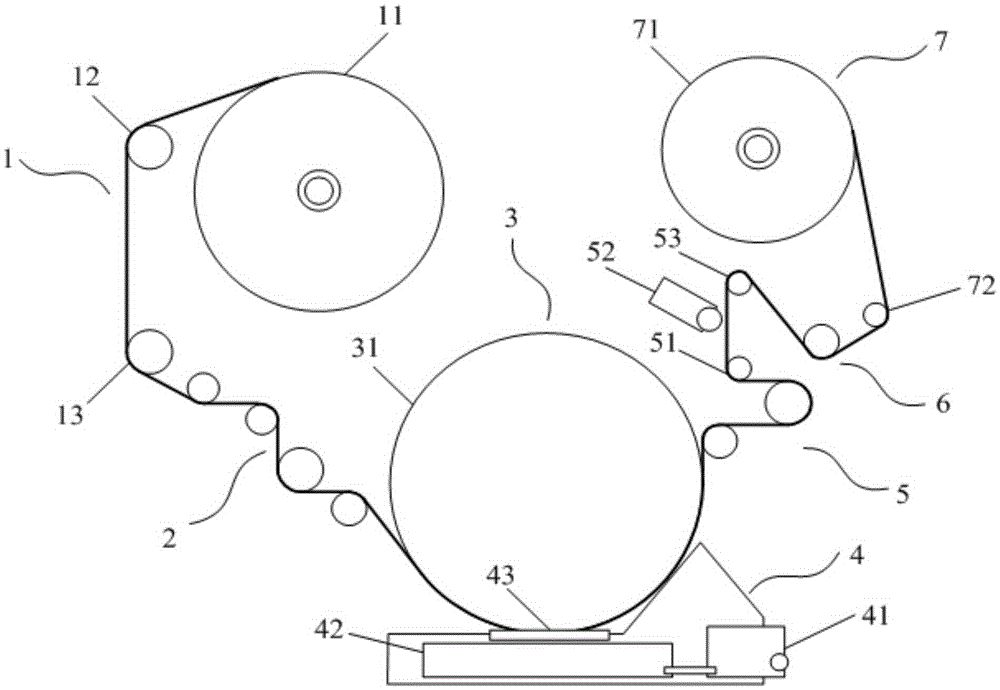

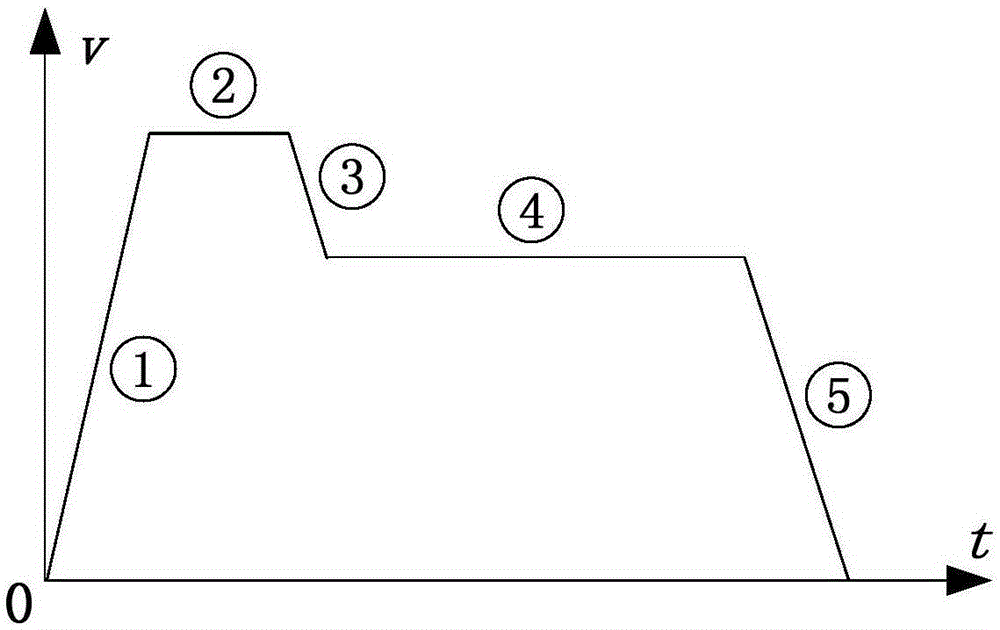

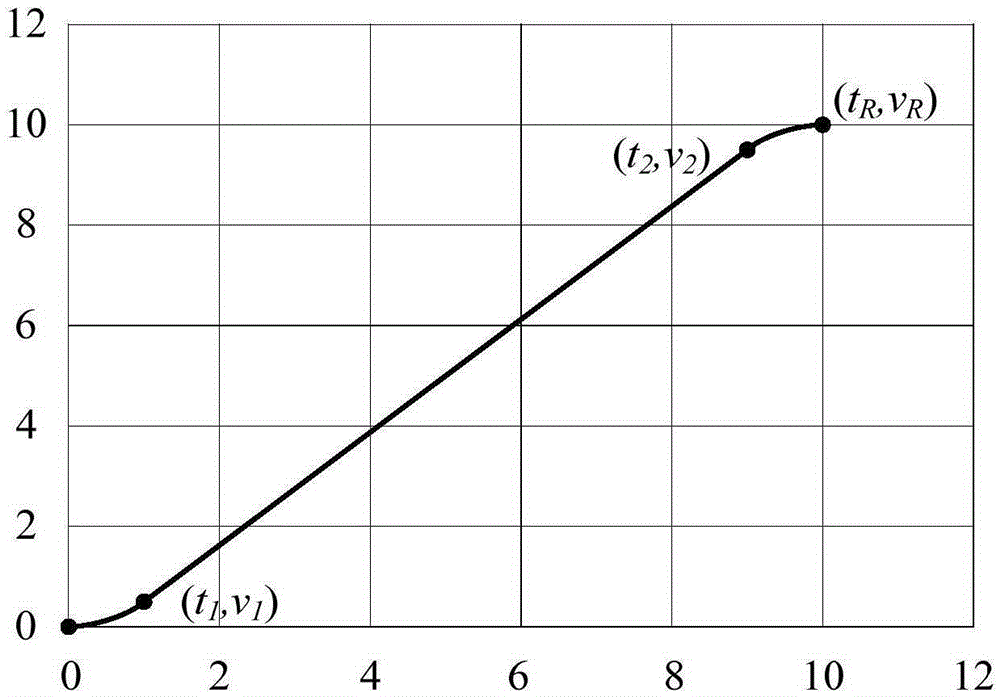

[0047] The embodiment of the present invention provides a vacuum coating high-speed constant winding tension equipment and control method, by adding a monitoring device and a control device to the traditional coating machine, and through the method of controlling the linear speed of the evaporation drum at each stage of the system operation, the acceleration of the evaporation drum The process slope function curve design method and the constant winding tension control method of the coating device realize the fully automatic process control of the film substrate from uncoiling, evaporation and winding, which is used to solve the tension and speed control of the film substrate in the prior art It is manually set and adjusted in real time during the coating process based on experience, resulting in high labor intensity, low coating efficiency and low product quality, and realizes real-time control of system tension and speed, improves production efficiency and coating quality, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com