Gasoline engine type tamping machine with transverse moving, rotating and multi-point tamping functions

A gasoline engine and tamping machine technology, which is applied to roads, tracks, ballast layers, etc., can solve the problems of low tamping efficiency, inconvenience of getting on and off the road, and high failure rate of the tamping pick, and achieve light weight, fast on and off the road, and long life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

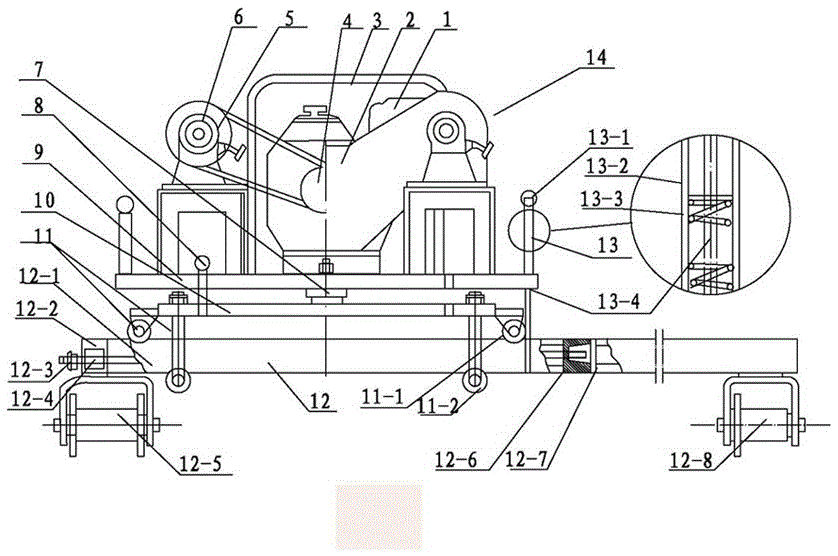

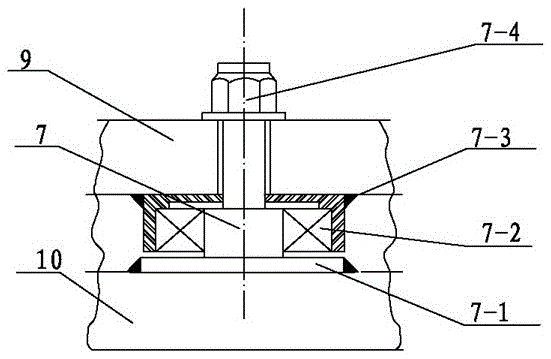

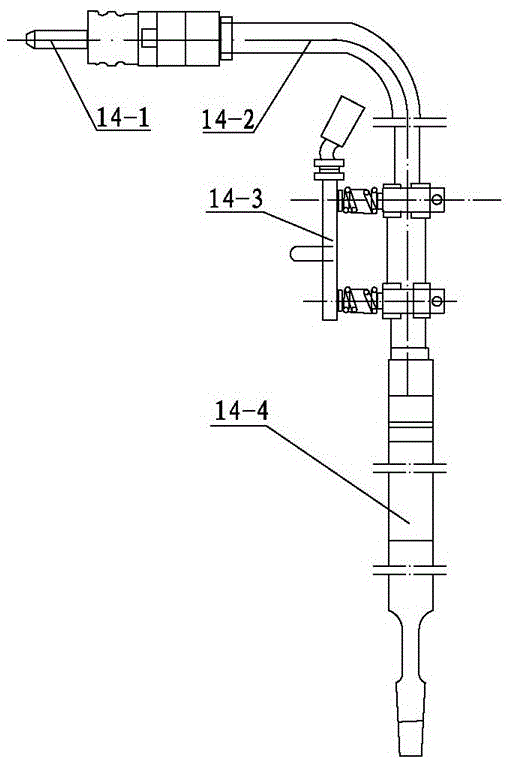

[0009] The details and working process of the present invention will be described in detail in conjunction with the accompanying drawings of the present invention. The gasoline engine 1 with the clutch 4, the belt transmission device 5 and two sets of output mechanisms 6 are fixed on the upper frame 9; the upper frame 9 is connected with the middle frame 10 through the rotating device 7, and is positioned with the positioning pin 8; Connected with the base frame 12, the traversing mechanism 11 is composed of two pairs of double-edged insulating wheels 11-1 and 11-2 which are respectively fixed to the middle frame 10 and roll on both sides of the beam 12-3 of the base frame 12; 12 walks on track, two cover tamping devices 14 each connect output mechanism 6 and realize multi-point tamping, and lifting handle 13 is equipped with on shelf 9 two ends. The rotating device 7 is made up of the shaft 7-1, the tapered roller bearing 7-2, the bearing sleeve 7-3 and the nut 7-4 fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com