Method for eliminating air-suction vortex at water inlet of pumping station under condition of beeline layout of gate and station

A technology for water inlets and pumping stations, applied in pumping stations, hydraulic models, water supply devices, etc., can solve problems that threaten the safe and stable operation of pumping stations, strong vibration of pump units, etc., and achieve easy popularization and application, simple methods, The effect of high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

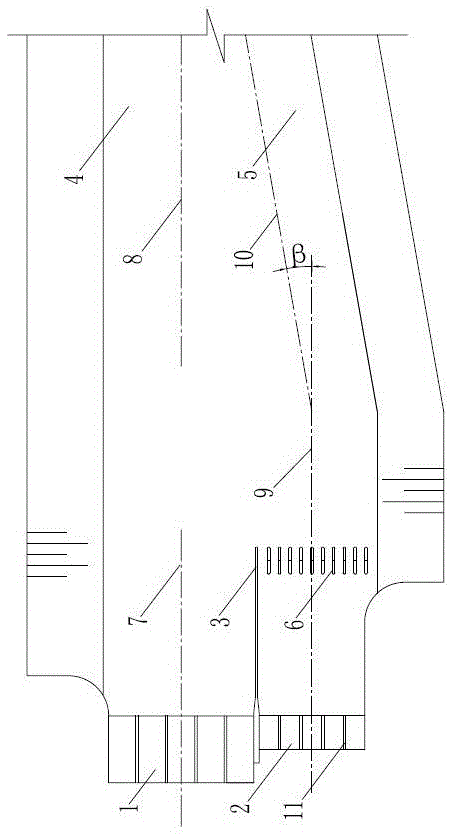

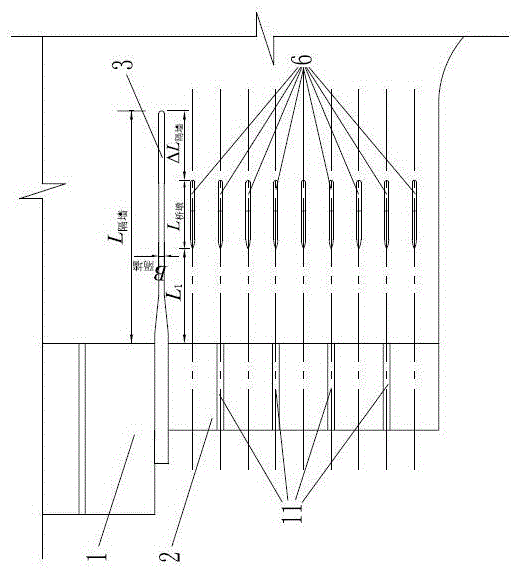

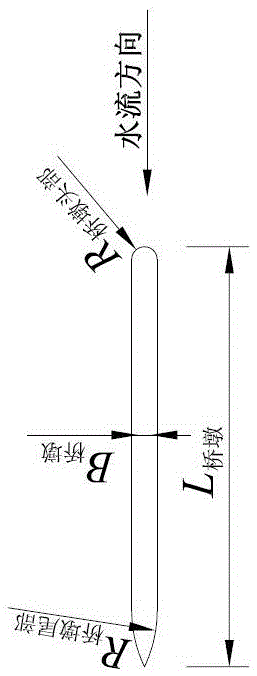

[0070] Such as Figure 6 As shown, a pumping station hub adopts the arrangement of gates and stations side by side. The pumping station 2 of the pumping station hub is equipped with 5 sets of vertical axial flow pump units, and the diameter of the pump impeller is D 0 The pumping station 2 has a length of 24.5m along the flow direction and a width of 38.9m in the vertical flow direction. The angle β between the centerline 9 of the pumping station and the centerline 10 of the diversion river is 10°. The control gate 1 of the pump station hub is divided into 5 holes, each hole has a net width of 10m, the length of the gate body along the water flow direction is 24.5m, and the width of the vertical water flow direction is 53.6m. According to the needs of the structure layout of the cleaning machine bridge, the length and width of the pier 12 of the cleaning machine bridge in the original design are 10m and 1m respectively.

[0071] The pier 12 of the cleaning machine bridge orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com